Limit condition adaptive protection design method suitable for deep space sampling high-power direct current motor

A DC motor and overcurrent protection technology, which is applied in the direction of emergency protection circuit device for limiting overcurrent/overvoltage, control generator, motor generator control, etc., can solve the problem of high cost, few components, and power device voltage and current impact, etc., to achieve the effect of both continuity and simple and reliable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The invention provides a method for synergistic protection of software and hardware under extreme working conditions of a high-power DC motor.

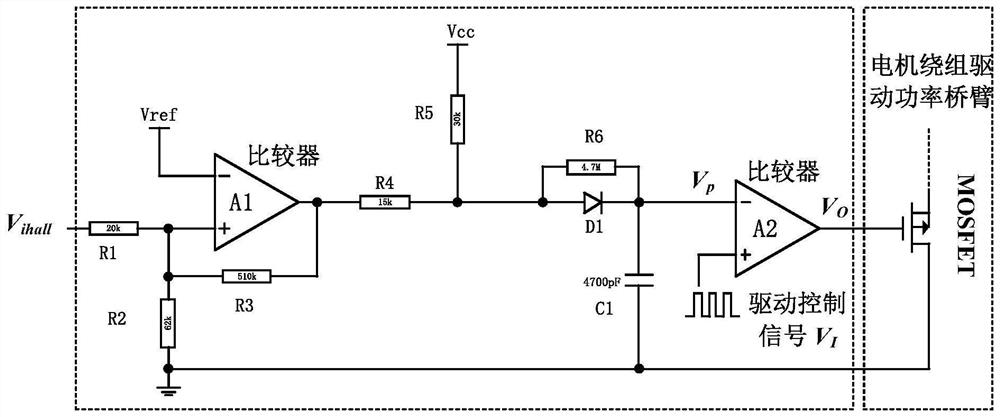

[0025] The topological circuit of software and hardware cooperative protection such as figure 1 shown.

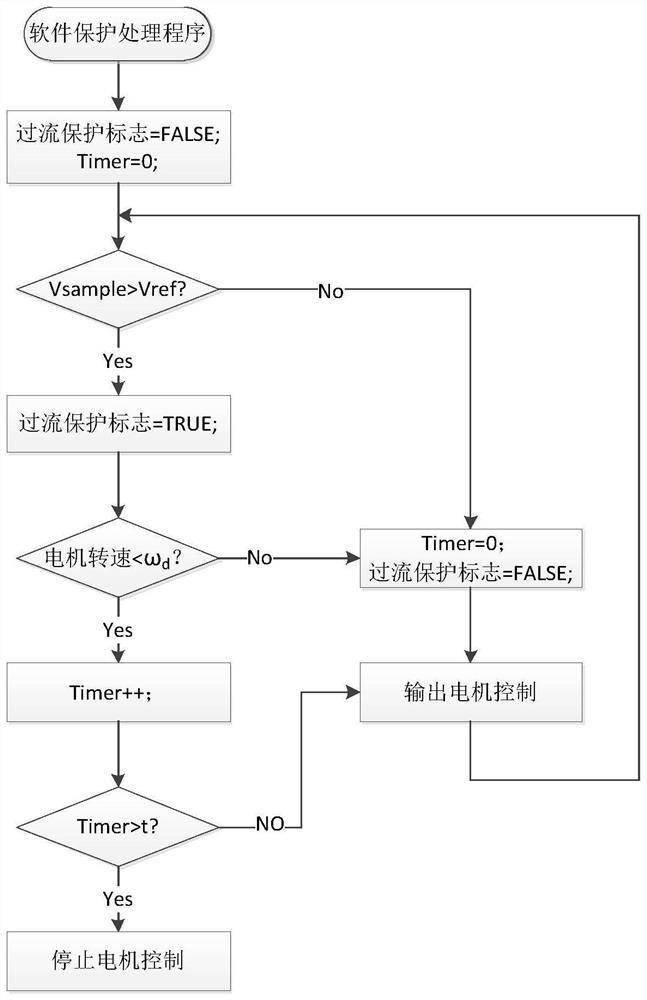

[0026] The specific control method of the software and hardware cooperative protection control process is as follows:

[0027] Step 1: Collect DC motor bus current. Usually, the method of measuring the voltage drop of the sampling resistor is used to measure and realize the detection of the motor bus current. The sampling resistor is generally placed at the negative end of the bus and connected in series with the motor load.

[0028] Step 2: The topology of the hardware protection circuit is as figure 1 As shown, the sampling voltage is output to the figure 1 In Vihall, another output to the control board for A / D acquisition. The Vihall signal is divided by resistors and compared with the reference voltage Vref. Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com