Preparation method and use method of complete feed for fattening cattle

A technology for full-price feed and fattening cattle, which is applied in the field of preparation of full-price feed for fattening cattle, can solve the problems that the growth needs of fattening cattle cannot be met, and the full-price ration cannot be used directly, and achieves improved palatability and fragrant taste. , the effect of restoring moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

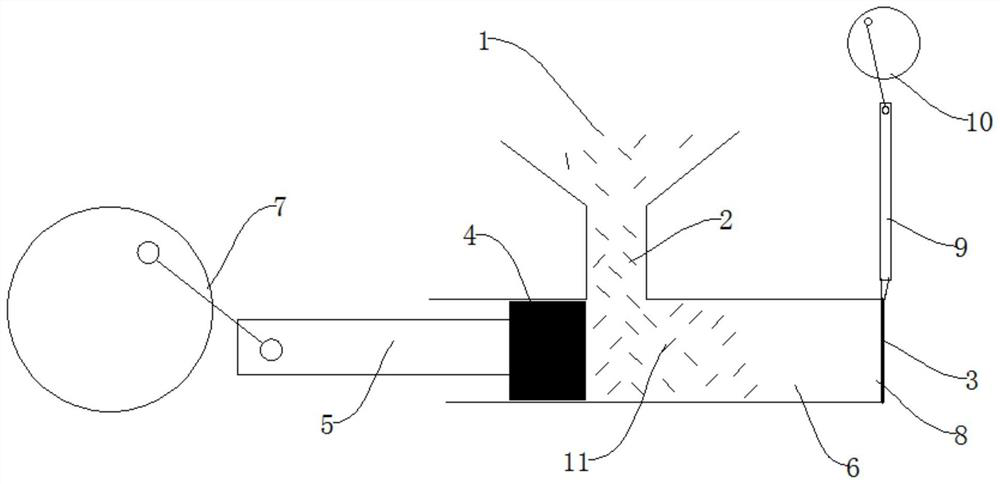

[0028] The present embodiment provides a briquetting machine, the structural diagram of the briquetting machine as shown Figure 1As shown, the briquetting machine comprises an inlet port 1, an inlet channel 2, a briquette channel 6, a baffle 3, a press block 4, a connecting rod 5 and a reciprocating compression mechanism 7, the feed port 1 and the feed channel 2 are connected, the feed channel 2 and the briquetting channel 6 are connected, and the feed channel 2 and the briquetting channel 6 together form a "T" shape; the briquette channel 6 at one end is provided with an outlet port 8, the outlet port 8 is provided with a baffle 3, the baffle 3 is movable, By the movement of the baffle 3 to achieve the opening and closing of the briquette channel 6; the connecting rod 5 and the briquette 4 are connected, and both are located in the briquette channel 6, the briquette 4 towards the baffle 3; the other end of the briquetting channel 6 is provided with a reciprocating compression mec...

Embodiment 2

[0032] The present embodiment is a method for preparing full-price feed for fattening cattle;

[0033] The method comprises the following steps:

[0034] (1) The freshly harvested corn straw processing growth rate of 8cm, the stalk diameter is less than 0.04cm of green material, the sugarcane tail leaves, wormwood processing growth of 8cm green material, and then the corn stalk, sugarcane tail leaf and wormwood mixed, dried until the moisture content is 12%, to obtain mixed green material backup; corn stalks, sugarcane tail leaves and wormwood are freshly picked, wherein the corn straw, sugarcane tail leaves and wormwood mass ratio of 2:2:1; the stalk diameter is the cross-sectional diameter or width of the straw;

[0035] (2) The tofu residue and cassava residue are mixed according to the ratio of 1:2 mass ratio, dried until the moisture content is 12%, and then the two are sent to the puffing machine for puffing treatment, the extruded concentrate is obtained, and then the puffed ...

Embodiment 3

[0039] The present embodiment is a method for preparing full-price feed for fattening cattle;

[0040] The method comprises the following steps:

[0041] (1) The freshly harvested corn straw processing growth rate of 7cm, the stalk diameter is less than 0.04cm of green material, the sugarcane tail leaves, wormwood processing growth of 7cm of green material, and then the corn straw, sugarcane tail leaves and wormwood mixed, dried until the moisture content is 14%, to obtain mixed green material standby; corn straw, sugarcane tail leaf and wormwood are freshly picked, wherein the corn straw, sugarcane tail leaves and wormwood mass ratio of 3:1:1; the stalk diameter is the cross-sectional diameter or width of the straw;

[0042](2) The tofu residue and cassava residue are mixed according to the ratio of 1:3 mass ratio, dried until the moisture content is 14%, and then the two are sent to the puffing machine for extrusion treatment, the extruded concentrate is obtained, and then the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com