Process for producing milk beverage by using ultrahigh pressure assisted browning and milk beverage

A technology for ultra-high pressure and milk beverages, which is applied in the direction of milk substitutes, dairy products, and other dairy products. It can solve the problems of difficulty in inhibiting and promoting Maillard reactions, complex structures of final products, and many reaction factors, so as to reduce browning. The effect of changing time and energy consumption, unique caramel flavor, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The present embodiment provides a browned soymilk beverage, wherein the soymilk preparation process adopted is the same as that of Comparative Example 1.

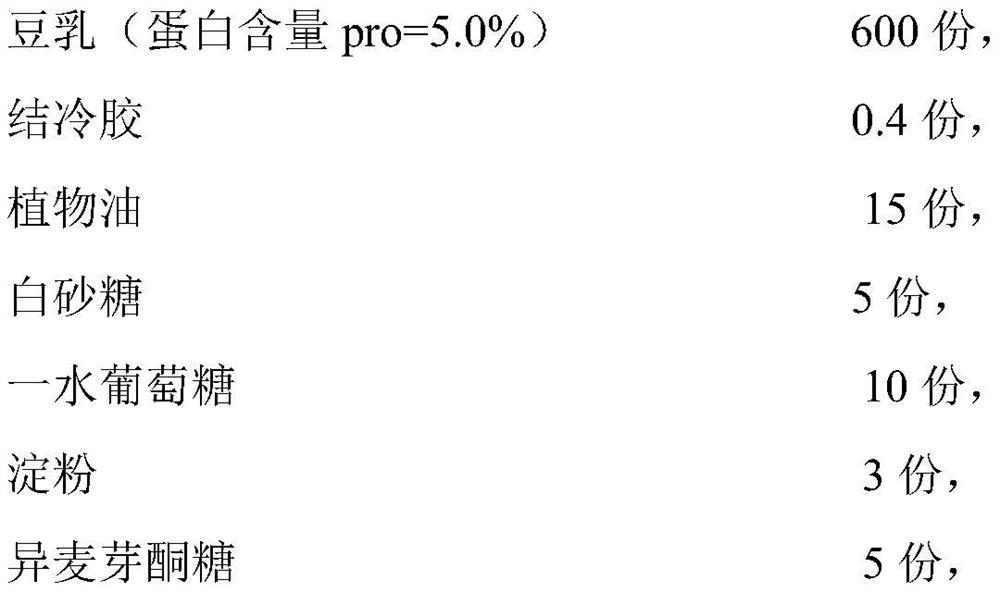

[0063] In 1000 parts by weight, the soymilk beverage includes the following raw materials by weight:

[0064]

[0065]

[0066] Make up 1000 parts by weight with water.

[0067] The soy milk drink is prepared according to the following steps:

[0068] Mix the raw materials of the soymilk drink, and perform the first homogenization. The homogenization pressure is 250bar for the primary pressure and 50bar for the secondary pressure;

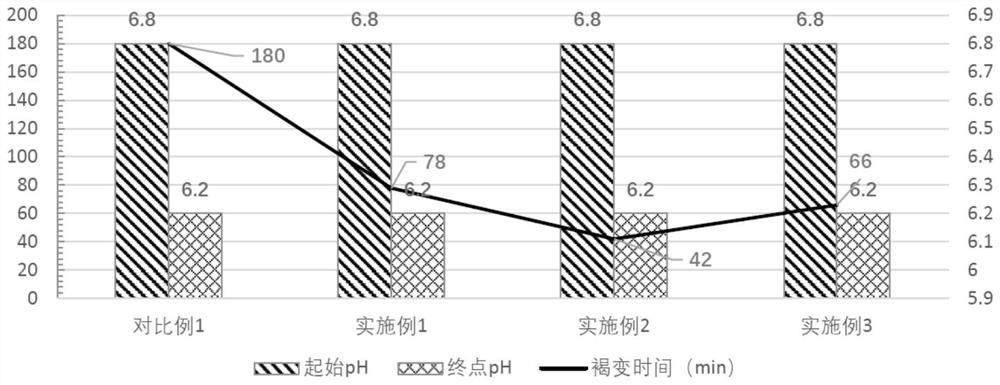

[0069] The homogenized material was browned to pH=6.2 under the conditions of 85°C and 200MPa, and the browning time was 78 minutes;

[0070] Perform secondary homogenization of the browned material, the homogenization pressure is 200bar for the primary pressure and 50bar for the secondary pressure;

[0071] Ultra-high temperature sterilization is carried out on the secondary hom...

Embodiment 2

[0073] The present embodiment provides a browned soymilk beverage, wherein the soymilk preparation process adopted is the same as that of Comparative Example 1.

[0074] In 1000 parts by weight, the soymilk beverage includes the following raw materials by weight:

[0075]

[0076] Make up 1000 parts by weight with water.

[0077] The soy milk drink is prepared according to the following steps:

[0078] Mix the raw materials of the soymilk drink, and perform the first homogenization. The homogenization pressure is 250bar for the primary pressure and 50bar for the secondary pressure;

[0079] The homogenized material was browned to pH=6.2 at 95°C and 400MPa, and the browning time was 42 minutes;

[0080] Perform secondary homogenization of the browned material, the homogenization pressure is 200bar for the primary pressure and 50bar for the secondary pressure;

[0081] Ultra-high temperature sterilization is carried out on the secondary homogenized material, the temperatur...

Embodiment 3

[0083] The present embodiment provides a browned soymilk beverage, wherein the soymilk preparation process adopted is the same as that of Comparative Example 1.

[0084] In 1000 parts by weight, the soymilk beverage includes the following raw materials by weight:

[0085]

[0086] Make up 1000 parts by weight with water.

[0087] The soy milk drink is prepared according to the following steps:

[0088] Mix the raw materials of the soymilk drink, and perform the first homogenization. The homogenization pressure is 250bar for the primary pressure and 50bar for the secondary pressure;

[0089] The homogenized material was browned to pH=6.2 at 90°C and 300MPa, and the browning time was 66 minutes;

[0090] Perform secondary homogenization of the browned material, the homogenization pressure is 200bar for the primary pressure and 50bar for the secondary pressure;

[0091] Ultra-high temperature sterilization is carried out on the secondary homogenized material, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com