Industrial solid waste polymer anti-seepage and anti-freezing material and preparation method thereof

An industrial solid waste and polymer technology, applied in the field of polymer concrete, can solve problems such as surface spalling, building material damage, unsafe incidents, etc., and achieve the effects of reducing the formation of connected pores, improving compactness, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides an industrial solid waste polymer impermeability and antifreeze material, and the industrial solid waste polymer impermeability and antifreeze material of this embodiment is prepared by the following steps:

[0035] Step 1, recycle industrial solid waste, remove impurities, and obtain fly ash and coal gangue respectively;

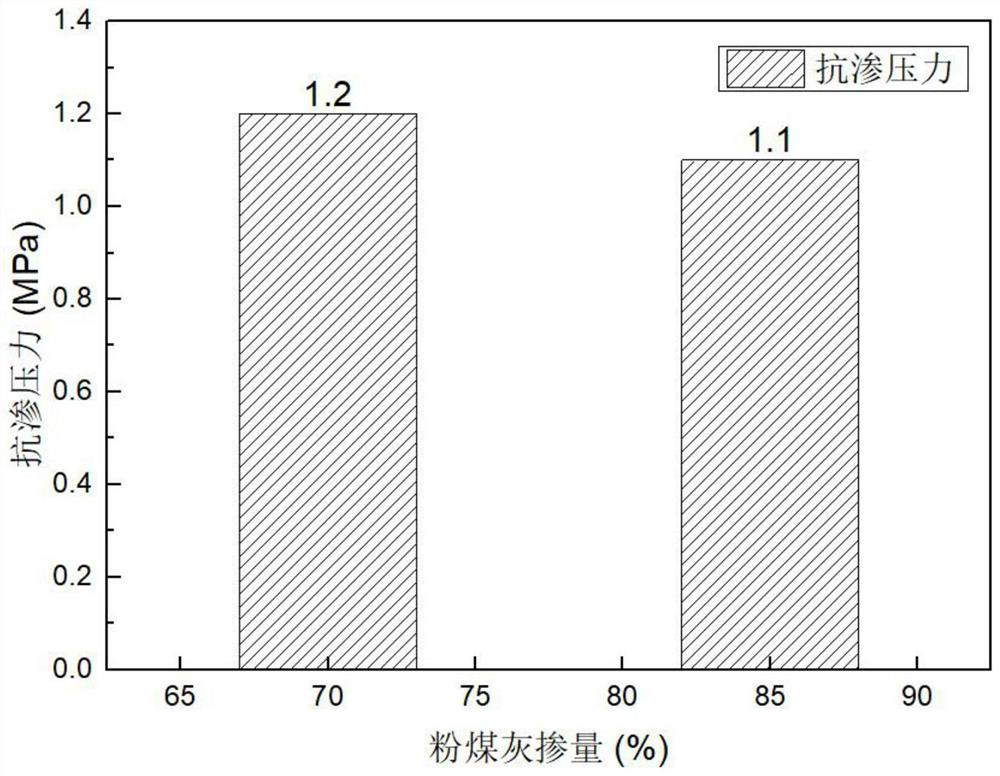

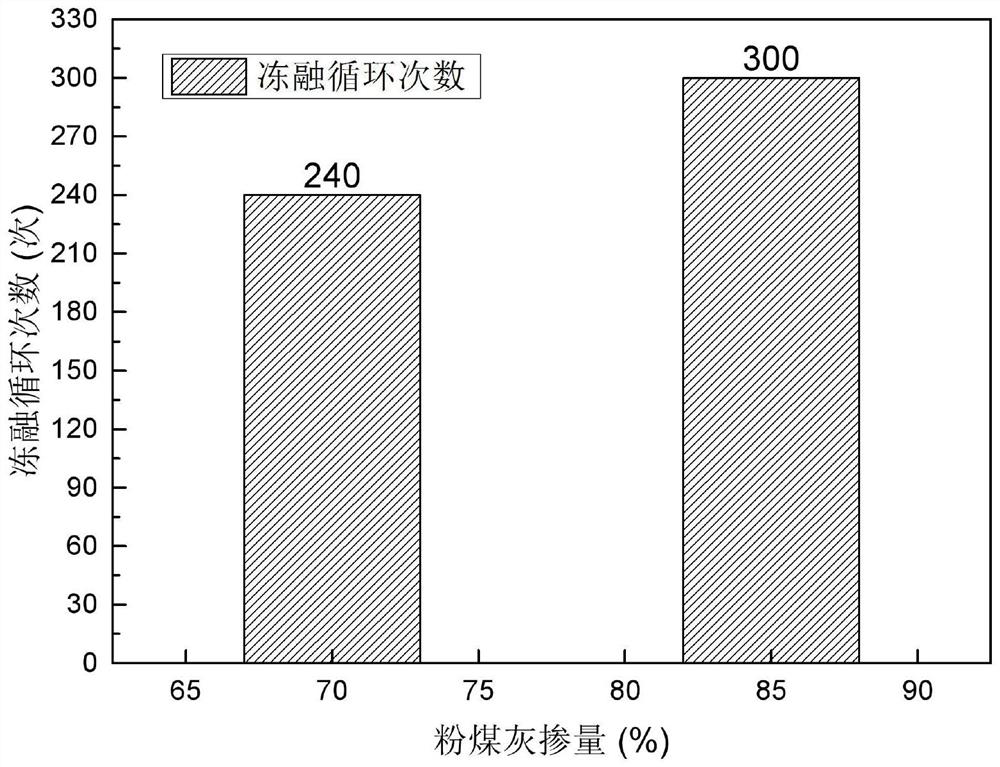

[0036] Grind the fly ash and coal gangue respectively to particles with a particle size of 0.1 mm, then, according to weight parts, take 85 parts of fly ash and 15 parts of coal gangue and send them to the mixer to mix evenly, and stir at a speed of 100r / min for 5min Then, add 0.4 parts of defoamer and 2.5 parts of granite rock powder, stir at 100r / min for 5min and mix well, then add 15 parts of alkaline activator, stir at 130r / min for 30min and mix well to form amorphous Aluminosilicate gel; then add 0.4 parts of water repellent and mix evenly to obtain the impermeable and antifreeze concrete material of industrial solid was...

Embodiment 2

[0045] This embodiment provides an industrial solid waste polymer impermeability and antifreeze material, and the difference between the preparation method of the industrial solid waste polymer impermeability and antifreeze material in this embodiment and Embodiment 1 is only:

[0046] In this embodiment, the weight parts of fly ash is 70 parts.

Embodiment 3

[0048] This embodiment provides an industrial solid waste polymer impermeability and antifreeze material, and the industrial solid waste polymer impermeability and antifreeze material of this embodiment is prepared by the following steps:

[0049] Step 1, recycle industrial solid waste, remove impurities, and obtain fly ash and coal gangue respectively;

[0050] Grind the fly ash and coal gangue to particles with a particle size of 0.15mm respectively, then, according to weight parts, take 60 parts of fly ash and 30 parts of coal gangue and send them to the mixer to mix evenly, and stir at a speed of 150r / min for 2min Then, add 0.2 parts of defoamer and 1.5 parts of granite rock powder, stir at 150r / min for 2min and mix well, then add 20 parts of alkaline activator, stir at 150r / min for 30min and mix well to form amorphous Aluminosilicate gel; then add 0.2 part of water repellent and mix evenly to obtain the impermeable and antifreeze concrete material of industrial solid waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com