Deep-sea oyster raft processing system adopting composite basalt fibers

A basalt fiber and processing system technology, applied in application, climate change adaptation, fish farming, etc., can solve problems to be strengthened, and achieve the effect of improving competitiveness, efficient processing process, and saving post-maintenance and upgrade costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

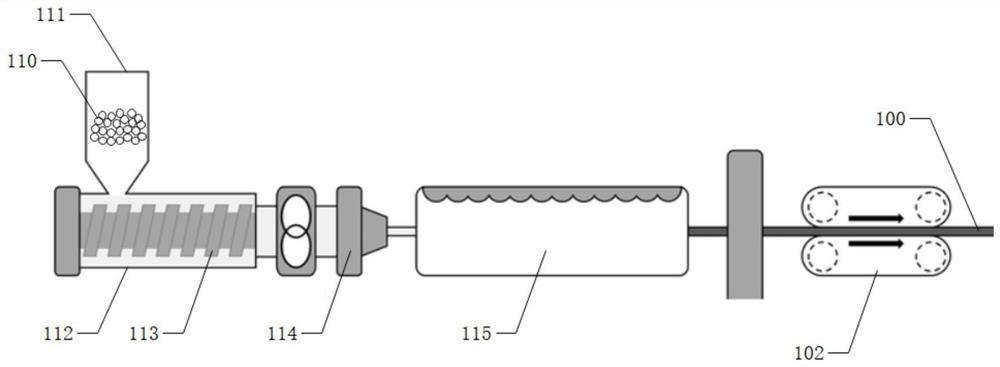

[0039] as attached figure 1 As shown, a deep-sea oyster steak processing system using composite basalt fiber, the processing system includes:

[0040] Extrusion unit 101 for forming connected composite tubes by continuously extruding molten material through an extrusion die;

[0041] a pulling unit 102 for pulling the composite pipe to flow in the processing system;

[0042] The rolling unit 103 is used for rolling the reinforcement grid;

[0043] an expansion unit, configured to further expand the formed reinforced grid in the composite pipe, and make the reinforced grid fit the inner wall of the composite pipe;

[0044] a control unit, used to communicate and connect the extrusion unit 101, the pulling unit 102, the rolling unit 103 and the expansion unit, and control the above units to work together;

[0045]Wherein, the expansion unit includes an umbrella-shaped openable expansion rack, and the expansion rack is stretched by extending the expansion rack along the axial ...

Embodiment 2

[0076] This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improved on the basis thereof;

[0077] In order to further keep the welding position fixed until cooling after the ultrasonic welding is completed, the present embodiment includes using an inflatable device to maintain the welding zone;

[0078] as attached Figure 8 As shown, the expansion rack 501 has 4 umbrella-shaped brackets, and the 4 umbrella-shaped brackets are evenly distributed in the circumference; the inflatable device includes 4 airbags, which are respectively located between every two umbrella-shaped brackets; the airbags are fixed on the central handle of the expansion rack, and connect and inflate with an external inflatable device, such as a compressor, through a trachea; after the inner gas is inflated, the airbag expands to the reinforcement grid, and further strengthens the reinforcement The mesh is pressed to the inner wal...

Embodiment 3

[0082] This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improved on the basis thereof;

[0083] When welding a composite pipe with a length of more than 2 meters, if the working arm extends too long, the farthest end of the working arm will have a significant deflection effect on the entire working arm due to the effect of gravity, thereby further reducing the machining accuracy;

[0084] In this embodiment, the expansion frame is used as the support of the working arm;

[0085] as attached Figure 9 As shown, the length of the center handle 601 of the expansion rack extends to just below the working arm; in this embodiment, the length of the center handle 601 extends toward the second end of the composite pipe until it exceeds the length of the first embodiment The second expansion rack is shown; and in some embodiments, the central handle 601 may extend between the first expansion rack and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com