Full-automatic mining dry dust collector based on PLC control

A dry dust collector, fully automatic technology, applied in chemical instruments and methods, separation methods, human health protection, etc., can solve the problems of reduced air suction, paralysis of dust removal systems, increased resistance, etc., to improve performance and reliability. , Improve the effect of blowing and cleaning, and increase the gas storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

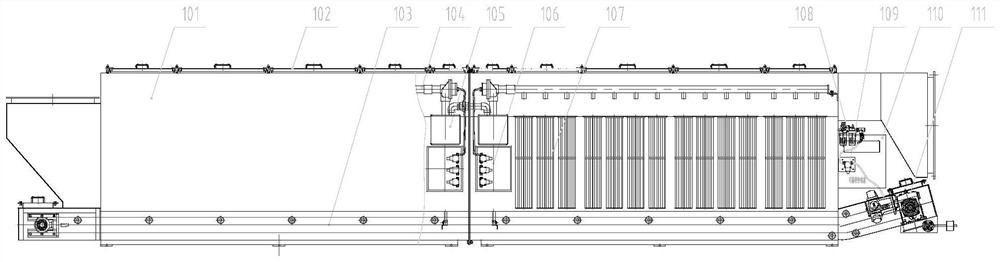

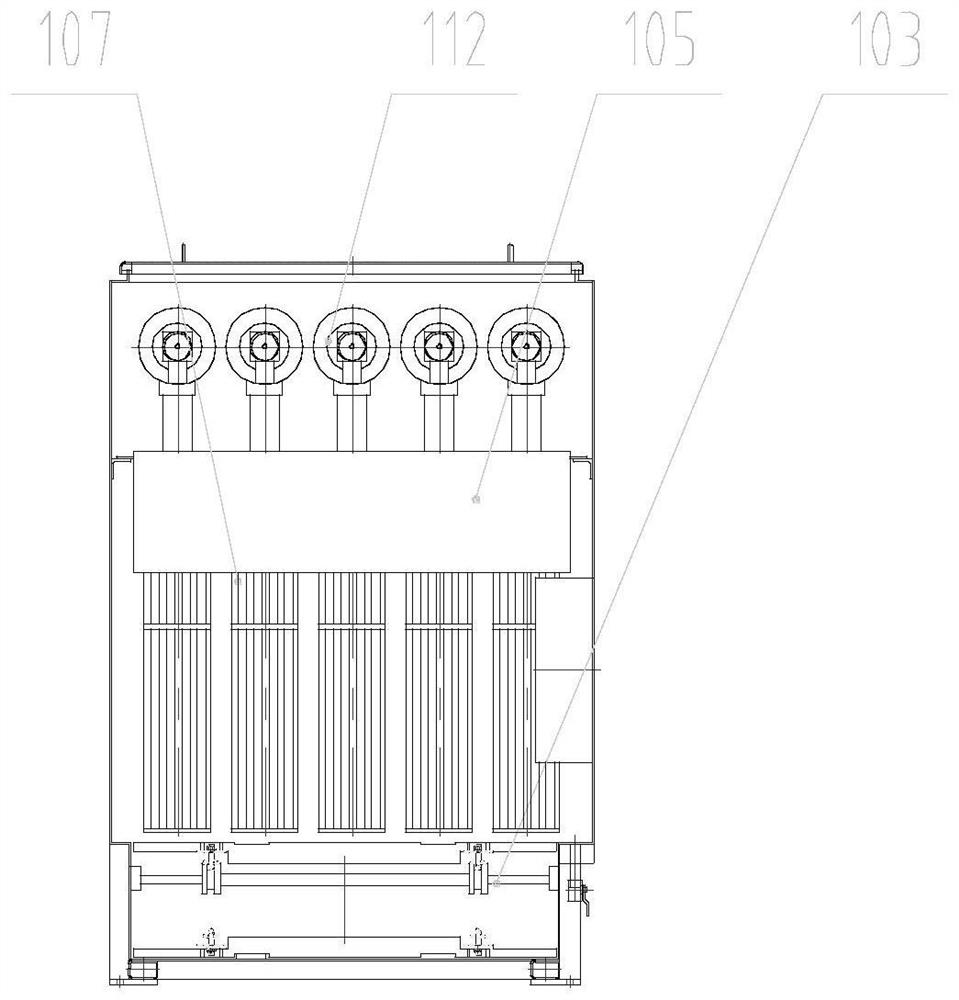

[0026] as Figure 1- Figure 3 As shown, a fully automatic mining dry dust collector based on PLC control, comprising the body part and the control part, the body part comprises a shell, a blowing ash cleaning device, a scraper ash conveying device 103, a filter cartridge 107, a compressed air system, the housing is composed of two boxes 101 in series, each box 101 is separated into upper and lower parts by a flower plate, the flower plate is branched and column fixed multiple filter cartridges 107, and the upper part of the filter cartridge 107 is arranged spraying ash cleaning device, The scraper ash conveying device 103 is arranged at the bottom of the box 101, the shell portion of the scraper ash conveying device 103 is indented inward from both sides of the box 101, and the housing of the dust collector is integrated into a structure, so that the height of the box 101 is reduced; the scraper ash conveying device 103 adopts an aerodynamic motor 111 transmission drive; the compre...

Embodiment 2

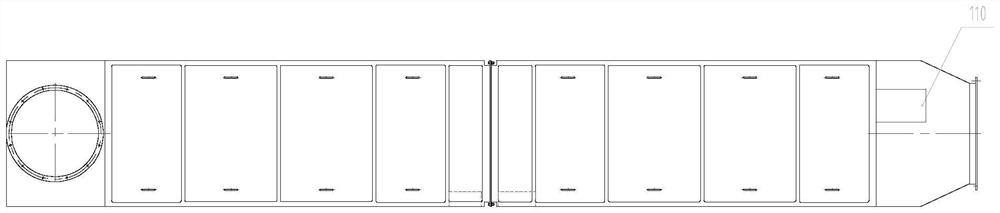

[0031] as Figure 4 、 Figure 5 、 Figure 6 Shown, is another way of structure of the present invention. The difference between Example II and the embodiment is that the direction of the access door 102 is arranged on the side panel of the box 101, and the air inlet is arranged in the horizontal direction. In addition, other structures are associated with Figure 1 、 Figure 2 、 Figure 3 Same.

[0032]The working principle of the present invention is: PLC control box 110 after the input power supply, in standby. When the main control signal input, such as the fan and other upper associated equipment start and stop signal, or when the differential pressure transmitter 5 input pressure exceeding the limit signal, the PLC control box 110 began to work, in turn to start the first pneumatic solenoid valve 109 or the second pneumatic solenoid valve 106. When opening the second pneumatic solenoid valve 106, the pneumatic pulse valve 112 will be connected to the pneumatic pulse valve 112 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com