Granulator

A granulator and machine body technology, applied in the direction of dispersed particle separation, dispersed particle filtration, separation methods, etc., can solve the problems of not having the function of forming particle size screening, not having the function of dust removal, etc., to reduce health impacts and reduce safety hazards , The effect of convenient retrieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

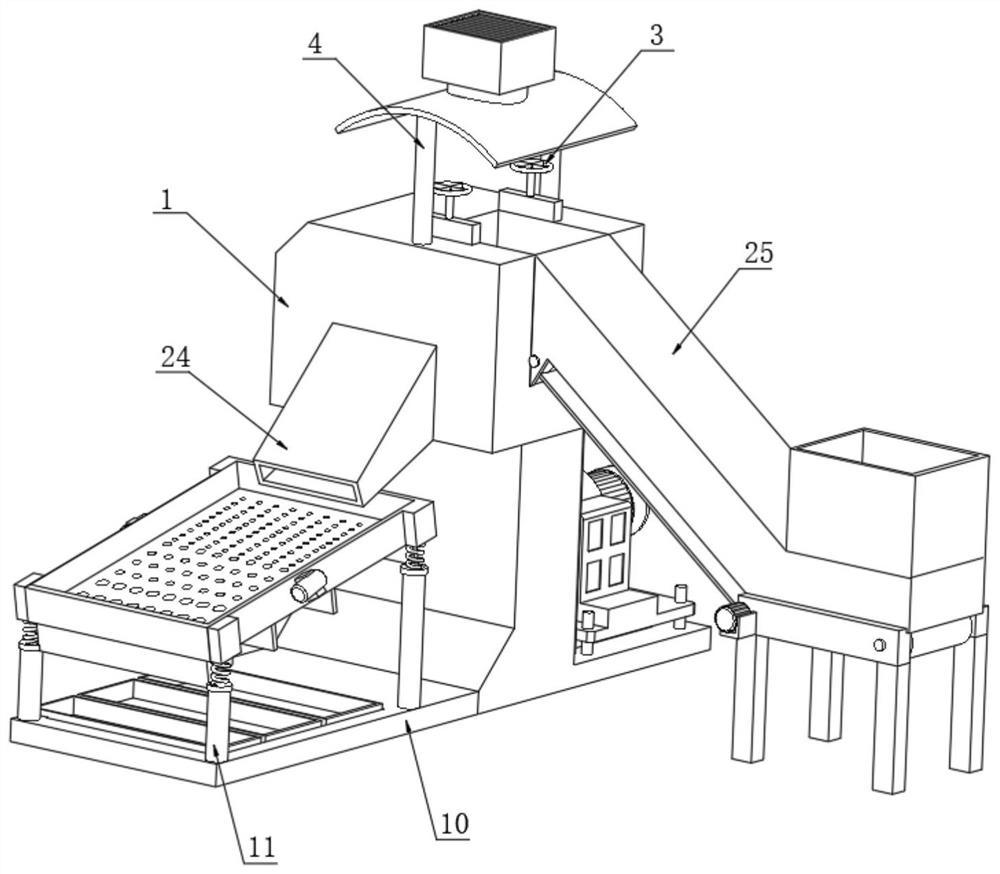

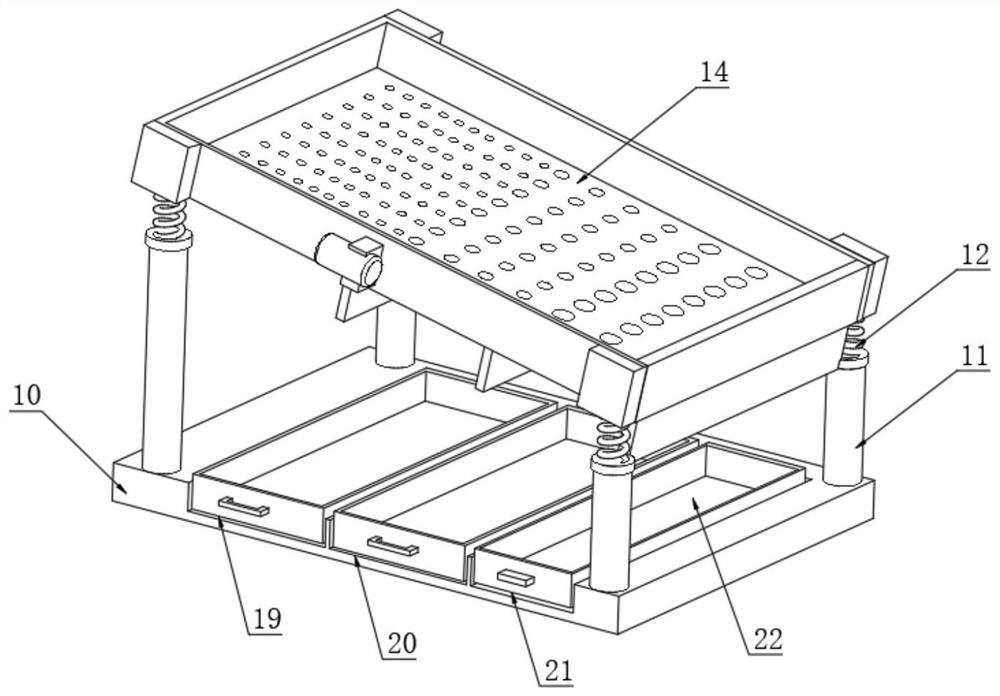

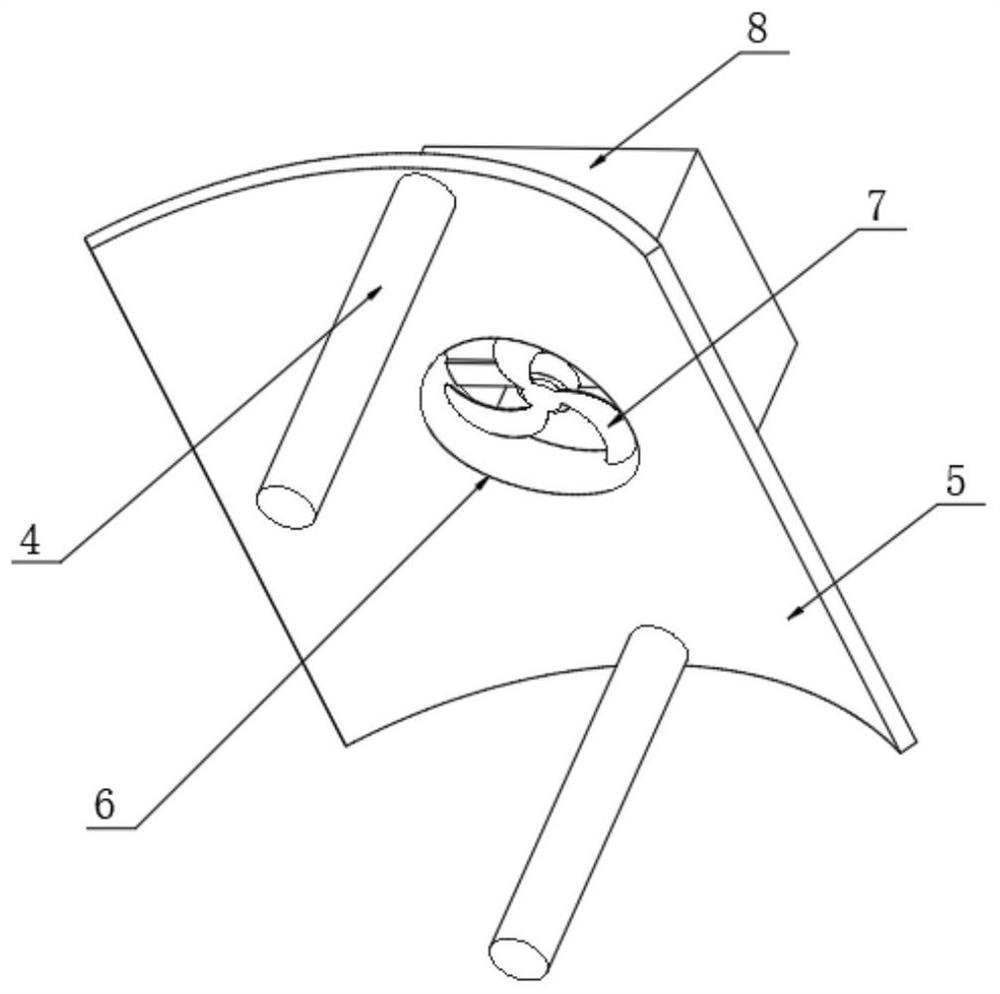

[0027] see Figure 1-6 , the present invention provides the following technical solutions: a pelletizer, comprising a body 1, a power bin 2 is installed on one side of the body 1, an adjusting wheel 3 is provided on the upper surface of the body 1, and one side of the upper surface of the body 1 is fixedly connected There is a support column 4, the top of the support column 4 is fixedly connected with a dust collecting plate 5, the upper surface of the dust collecting plate 5 is provided with a through hole 6, the fan 7 is installed inside the through hole 6, and one side of the outer surface of the through hole 6 is fixed A fixed box 8 is connected, the interior of the fixed box 8 is fixedly connected with a filter screen 9, the side of the outer surface of the body 1 close to the bottom is fixedly connected with a base 10, the upper surface of the base 10 is fixedly connected with a column 11, and the upper surface of the column 11 is fixed A spring 12 is attached.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com