Down jacket with high thermal insulation performance and preparation method thereof

A down jacket and performance technology, applied in the field of garment processing, can solve the problems of poor thermal insulation effect, thin down jacket, poor thermal insulation effect, etc., and achieve the effects of preventing coating from falling off, good heat storage and thermal insulation performance, and improving bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

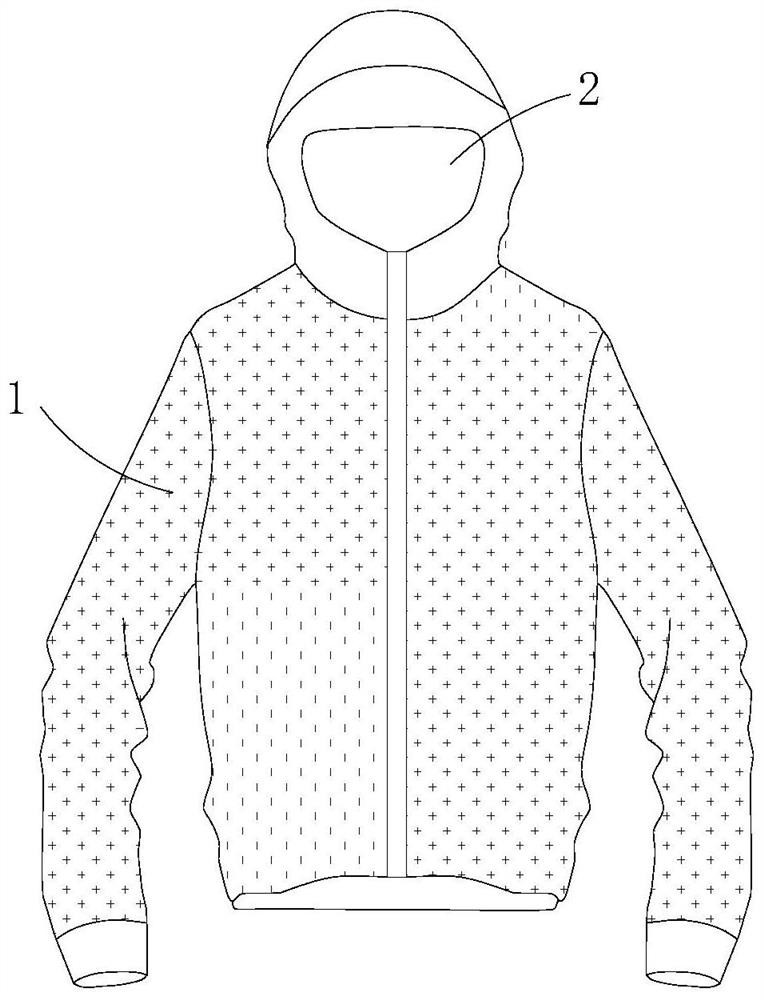

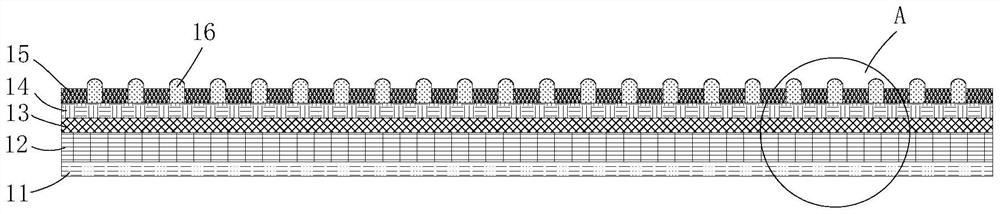

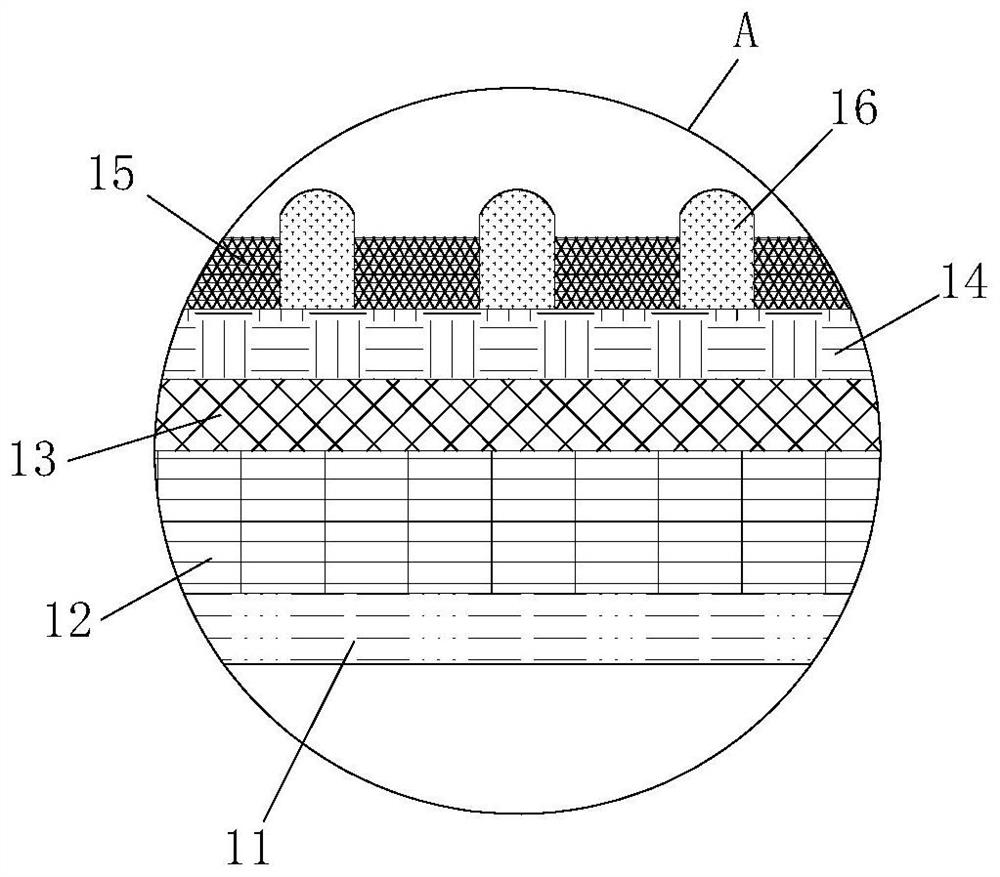

[0031] like Figure 1-3 As shown, a down jacket with high thermal insulation performance includes a fabric 1, a lining 2, and a down set between the fabric 1 and the lining 2. The fabric 1 includes a blended fabric layer 11, a first Insulation layer 12 , elastic fiber layer 13 , second insulation layer 14 , printing layer 15 .

[0032] Wherein, the first heat insulation layer 12 and the second heat insulation layer 14 are both bonded to the adjacent layers by using a water emulsion adhesive formed by 20 parts of coating PU glue and 80 parts of epoxy resin adhesive.

[0033] Among them, the ultrafine mineral fiber reinforced SiO 2 The first thermal insulation layer 12 is obtained by mixing the aerogel and the rigid polyurethane foam resin at 60-80°C.

[0034] The second heat insulating layer 14 is obtained by blending 70% of Nomex fibers and 30% of kaifula fibers by weight.

[0035] Among them, the printing layer 15 is evenly provided with a plurality of resin protruding end...

Embodiment 2

[0045] like Figure 1-3 As shown, a down jacket with high thermal insulation performance includes a fabric 1, a lining 2, and a down set between the fabric 1 and the lining 2. The fabric 1 includes a blended fabric layer 11, a first Insulation layer 12 , elastic fiber layer 13 , second insulation layer 14 , printing layer 15 .

[0046] Wherein, the first heat insulating layer 12 and the second heat insulating layer 14 are both bonded to the adjacent layers using a water emulsion adhesive formed by 30 parts of coating PU glue and 70 parts of epoxy resin adhesive.

[0047] Among them, the ultrafine mineral fiber reinforced SiO 2 The first thermal insulation layer 12 is obtained by mixing the aerogel and the rigid polyurethane foam resin at 60-80°C.

[0048] The second heat insulating layer 14 is obtained by blending 70% of Nomex fibers and 30% of kaifula fibers by weight.

[0049] Among them, the printing layer 15 is evenly provided with a plurality of resin protruding ends 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com