Straight-through type honeycomb filler biological membrane reaction system

A honeycomb filler and reaction system technology, applied in sustainable biological treatment, biological water/sewage treatment, water pollutants, etc. Transfer rate and utilization of dissolved oxygen, enhanced gas transfer efficiency, uniform and sufficient aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

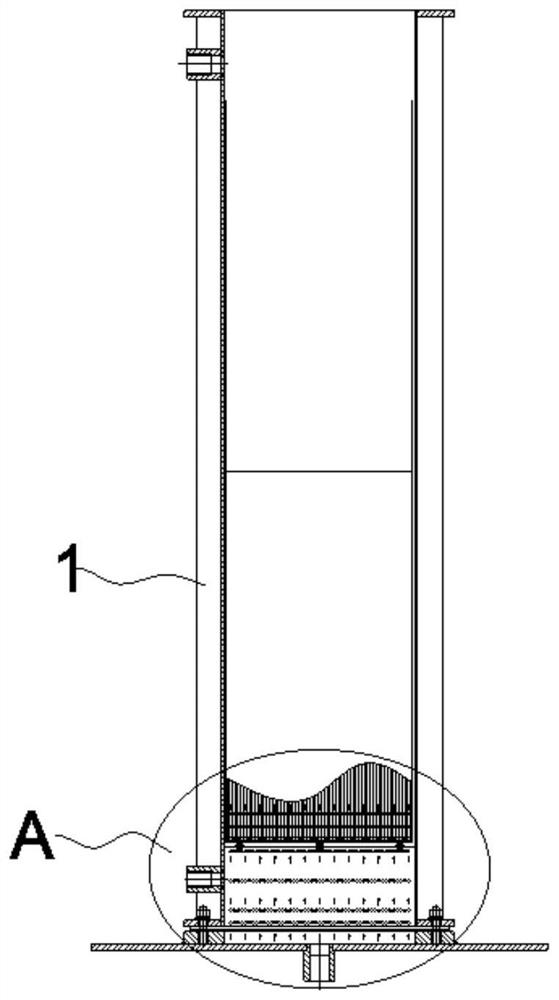

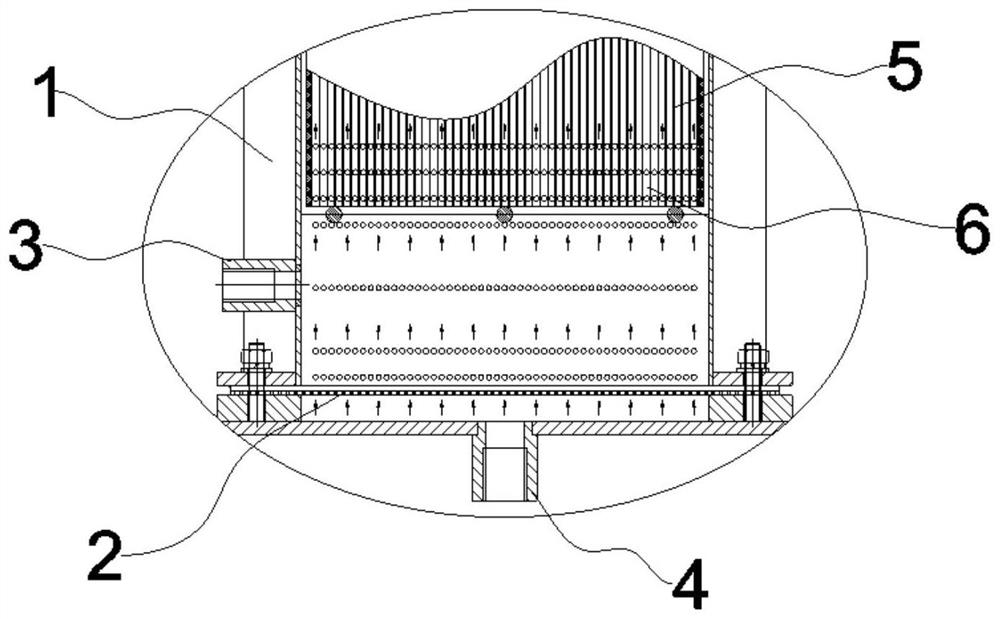

[0026] Using the straight-through honeycomb packing biofilm reaction system provided by the present invention nitrification treatment of the above-described river sewage, by adding honeycomb packing 5 to achieve a biological hanging film, the packing 5 is a cube, the structural form of aperture 6 is a straight-through honeycomb distribution, the pore diameter is 5mm.

[0027] The aeration device provides oxygen to the reaction system, and the microorganisms nitrify under aerobic conditions to achieve the removal of ammonia nitrogen. The distribution density of the pores of the aeration film 2 of the aeration device is not lower than the distribution density of the filler 5 pores 6.

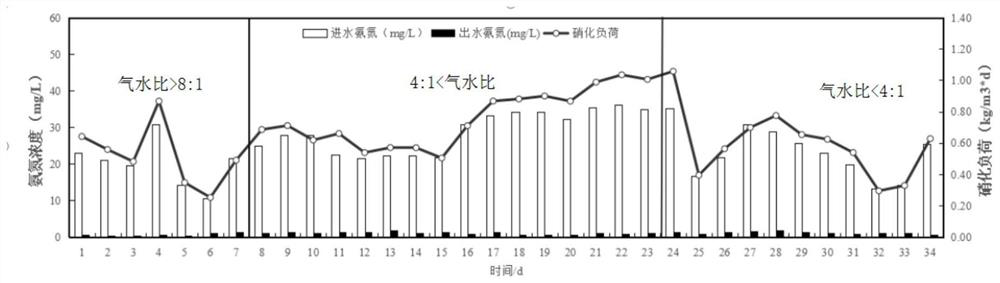

[0028] See Figure 3 , hanging film stage:

[0029] After the installation of the equipment, the filler 5 is added to the reaction tank 11, and the inlet and inlet operation is carried out through the aeration pipe 4 and the inlet pipe 3 after the packing 5 is completed, and the water inlet is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com