Hydrated and carbonized composite hardened cementing material based on steel slag and preparation method of hydrated and carbonized composite hardened cementing material

A cementitious material and hardening technology, applied in the field of hydration carbonization composite hardening cementitious material and its preparation, can solve the problems of low carbonization hardening body strength, high consumption of natural ore, narrow application range, etc. Dispersion, design science, the effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

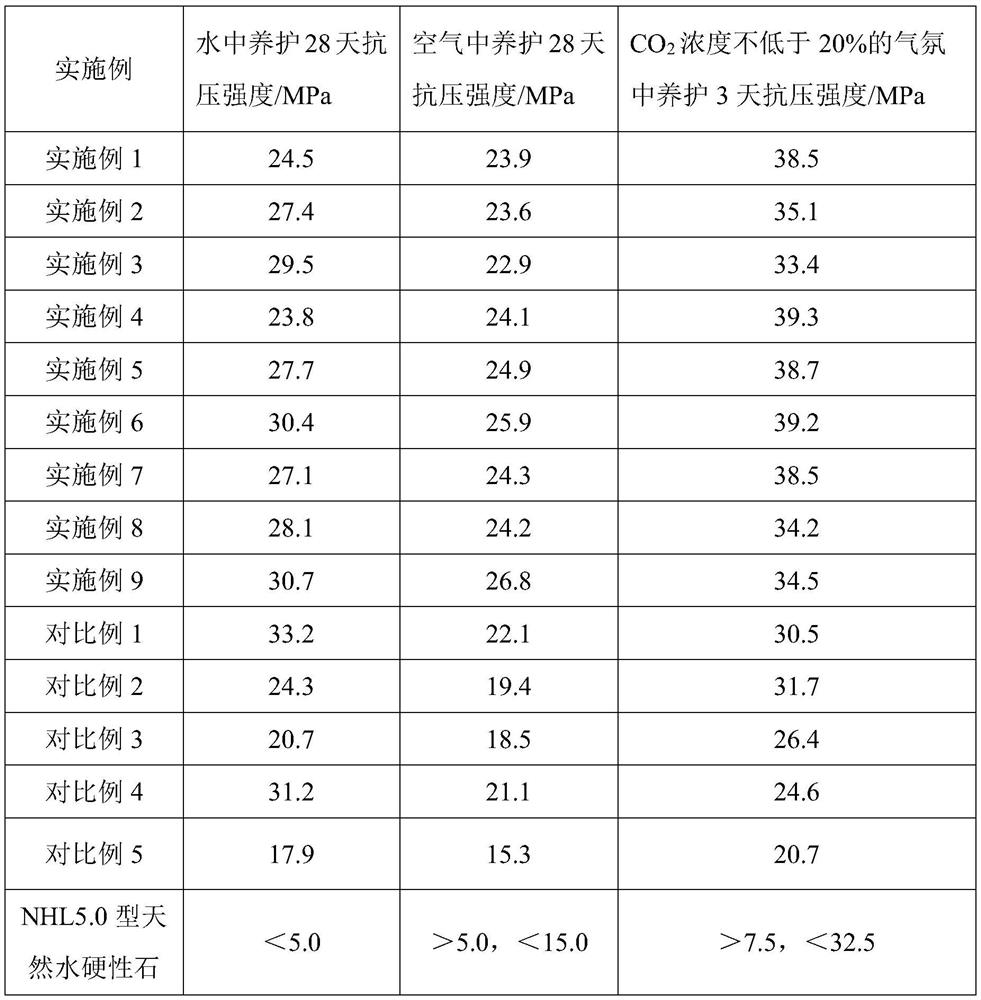

Examples

preparation example Construction

[0051] The preparation method of the hydration carbonization composite hardening cementitious material based on steel slag of the present invention comprises the following steps:

[0052] S1. Ingredients: prepare each raw material according to the mass percentage;

[0053] S2. Iron selection: the prepared raw materials are sent to the magnetic separator, and the magnetic iron and its oxides in the raw materials are selected;

[0054] S3. Grinding: Grind the mixed raw material from which the magnetic iron has been removed through the iron selection operation into powder to obtain a hydrated carbonized composite hardening cementitious material based on steel slag.

[0055] Preferably, after the iron selection is completed, the animal protein hydrolyzed liquid accounting for 0.05-0.5% of the raw material mass is sprayed into the raw material, fully mixed with the raw material, and then ground; preferably, the animal protein hydrolyzed liquid accounting for 0.1% of the raw materia...

Embodiment 1

[0063] The present embodiment discloses the preparation method of the steel slag-based hydration carbonization composite hardening cementitious material of the present invention, specifically:

[0064] S1. Preparation of raw materials: by mass percentage, 25% of cement clinker, 25% of pretreated carbide slag, 1.5% of industrial by-product gypsum, 5% of bentonite, 1% of hydration and carbonization accelerator and the balance The proportion of the steel slag (42.5%) is taken as the raw materials of each component. The total amount of raw materials is 100kg, including 25kg of cement clinker, 25kg of pretreated carbide slag, 1.5kg of industrial by-product gypsum, 5kg of bentonite, 1kg of hydration carbonization accelerator, and 42.5kg of steel slag.

[0065] S2. iron selection: the prepared raw materials enter the magnetic separator, and the magnetic iron and its oxides in the materials such as steel slag and carbide slag are selected;

[0066] S3. Grinding: After the raw materia...

Embodiment 2

[0069] The present embodiment discloses the preparation method of the steel slag-based hydration carbonization composite hardening cementitious material of the present invention, specifically:

[0070] S1. Preparation of raw materials: by mass percentage, 28% of cement clinker, 25% of pretreated carbide slag, 1.8% of industrial by-product gypsum, 5% of bentonite, 1.0% of hydration and carbonization accelerator and the balance The proportion of the steel slag (39.2%) is taken from the raw materials of each component. The total amount of raw materials is 100kg, including 28kg of cement clinker, 25kg of pretreated carbide slag, 1.8kg of industrial by-product gypsum, 5kg of bentonite, 1kg of hydration and carbonization accelerator, and 39.2kg of steel slag.

[0071] S2. Iron selection: The prepared raw materials enter the magnetic separator, and the magnetic iron and its oxides in the steel slag, carbide slag and other materials are selected;

[0072] S3. Grinding: After the raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com