Patents

Literature

35results about How to "Has a grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

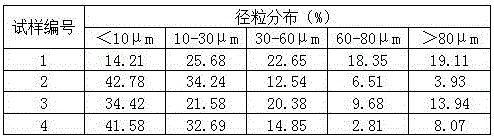

Method of preparing superfine modified powder by composite grinding and modification

InactiveCN1475310AHas a grinding effectRealize modified treatmentMicrowave heatingGrain treatmentsScience and engineeringAirflow

Owner:WUHAN UNIV OF TECH

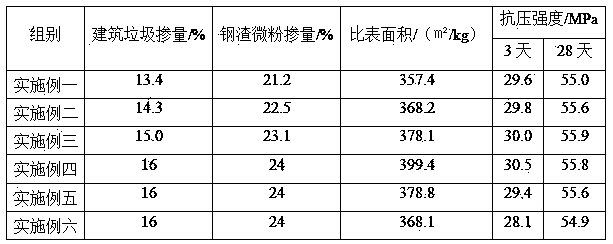

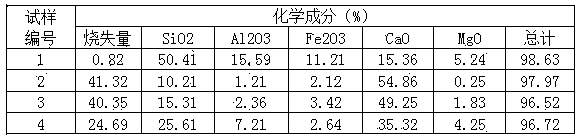

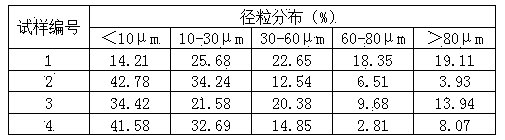

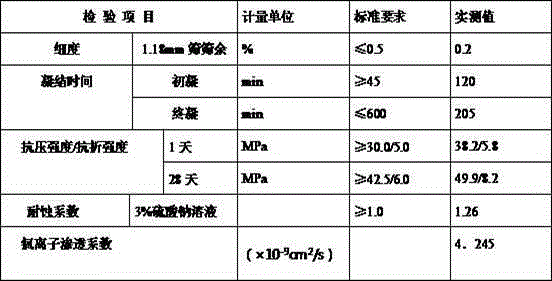

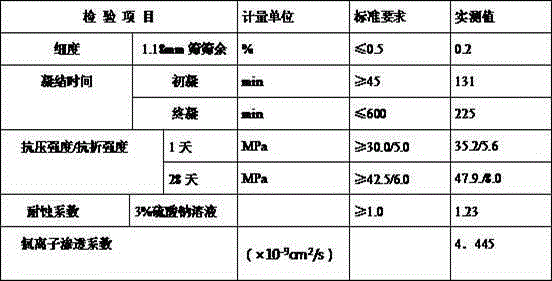

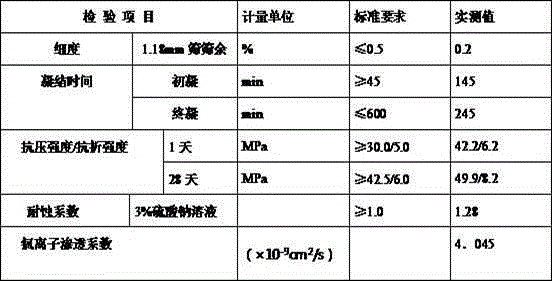

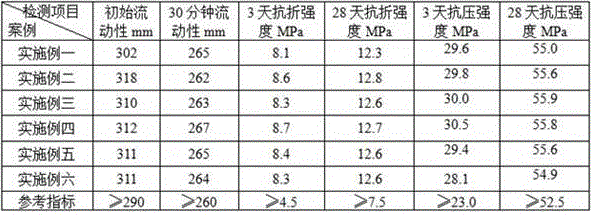

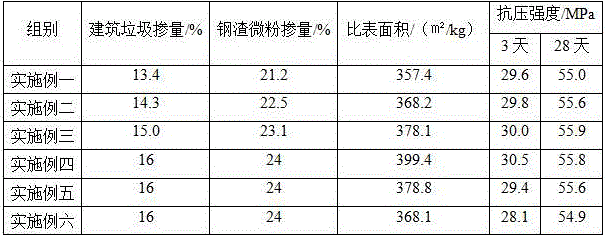

Method for producing green ecological cement resistant to seawater corrosion by using construction wastes

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using construction wastes. The cement comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinkers, 5-20 parts of construction wastes, 20-25 parts of steel slag powder, 0.06-0.08 part of compound activating agent, 2-5 parts of early strength agent, 0.3-0.5 part of water reducing agent, 0.005-0.007 part of air entraining agent and 0.3-0.5 part of retarder. The production method is characterized by breaking, grinding and homogenizing the construction wastes, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Method for producing seawater corrosion-resistant green ecological cement from stone waste

ActiveCN104291717AReduce stone dust pollutionWide variety of sourcesCement productionScrapCorrosion resistant

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste. The seawater corrosion-resistant green ecological cement comprises the following raw materials in parts by weight: 30-40 parts of stone waste, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of a complex activator, 2-4 parts of an early-strength agent, 0.3-0.5 part of a water-reducing agent, 0.005-0.007 part of an air entraining agent, and 0.3-0.5 part of a retarder; and the production method comprises the following steps: respectively crushing the stone waste, sulphate aluminum cement clinker, complex activator and early-strength agent, grinding, homogenizing, then mixing and homogenizing according to a proportion, then adding the water-reducing agent, air entraining agent and the retarder, mixing and homogenizing to obtain the seawater corrosion-resistant green ecological cement. The seawater corrosion-resistant green ecological cement has the excellent properties of being high-strength, seawater corrosion-resistant, seawater scouring-resistant and the like besides the performances of common cement, and is especially applicable to underground engineering, ports, wharfs and other engineering corroded by erosion media.

Owner:广西云燕特种水泥建材有限公司

Green ecological cement with stone wastes as raw material and production method of green ecological cement

The invention discloses green ecological cement with stone wastes as raw materials and a production method of the green ecological cement. The green ecological cement comprises the following raw materials in parts by weight: 30-40 parts of stone wastes, 40-50 parts of Portland cement clinker, 0.03-0.05 part of a complex activator and 2-4 parts of an early strength agent. The cement clinker is Portland cement with the grade being more than 52.5, and the stone wastes are mixtures of marble powder and granite powder. The production method comprises the following steps of drying, burdening, grinding and homogenizing the raw material to obtain the green ecological cement. According to the method for producing the green ecological cement with the stone waste as the raw material, by adulterating the stone waste, the proportion of the clinker in the cement is reduced, the product cost is reduced, the performance of the cement is improved, and stone powder pollution caused by stone processing industry can be substantially reduced.

Owner:XINCHENG COUNTY HONGYUN CEMENT

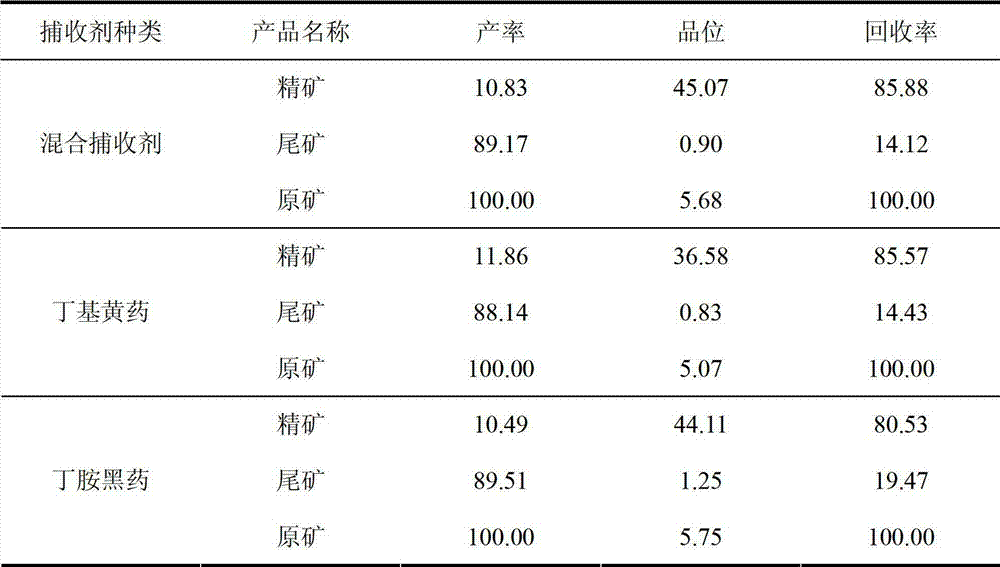

Collecting agent for copper converter slag flotation and use method thereof

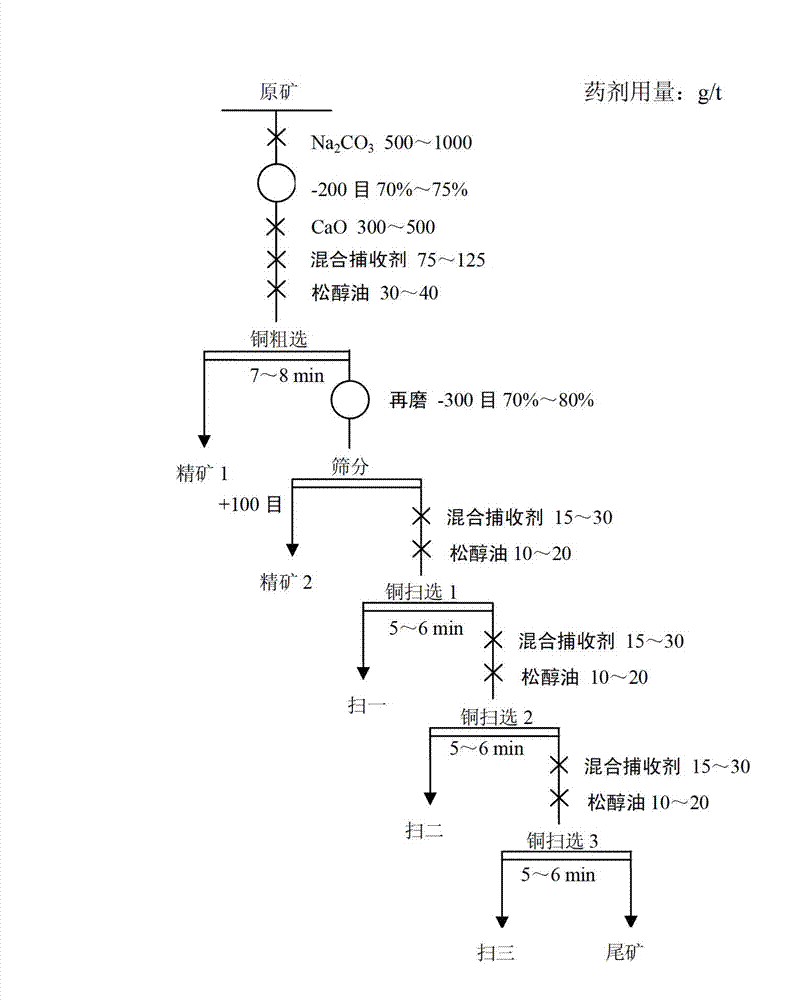

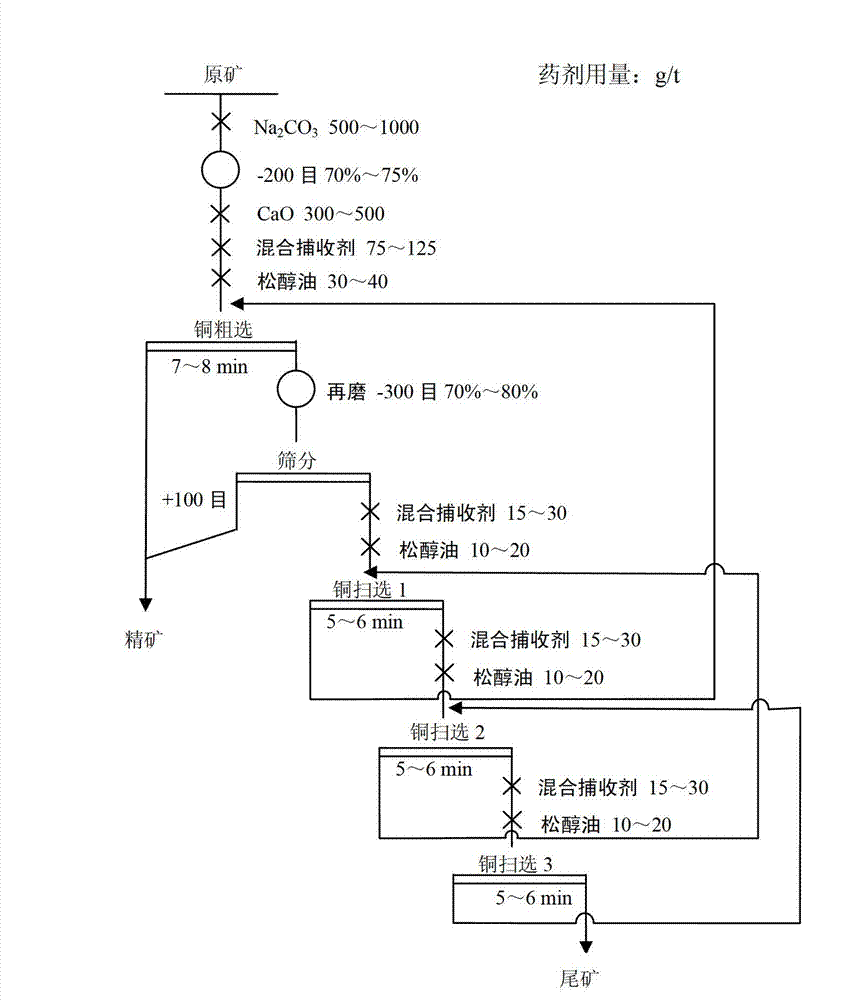

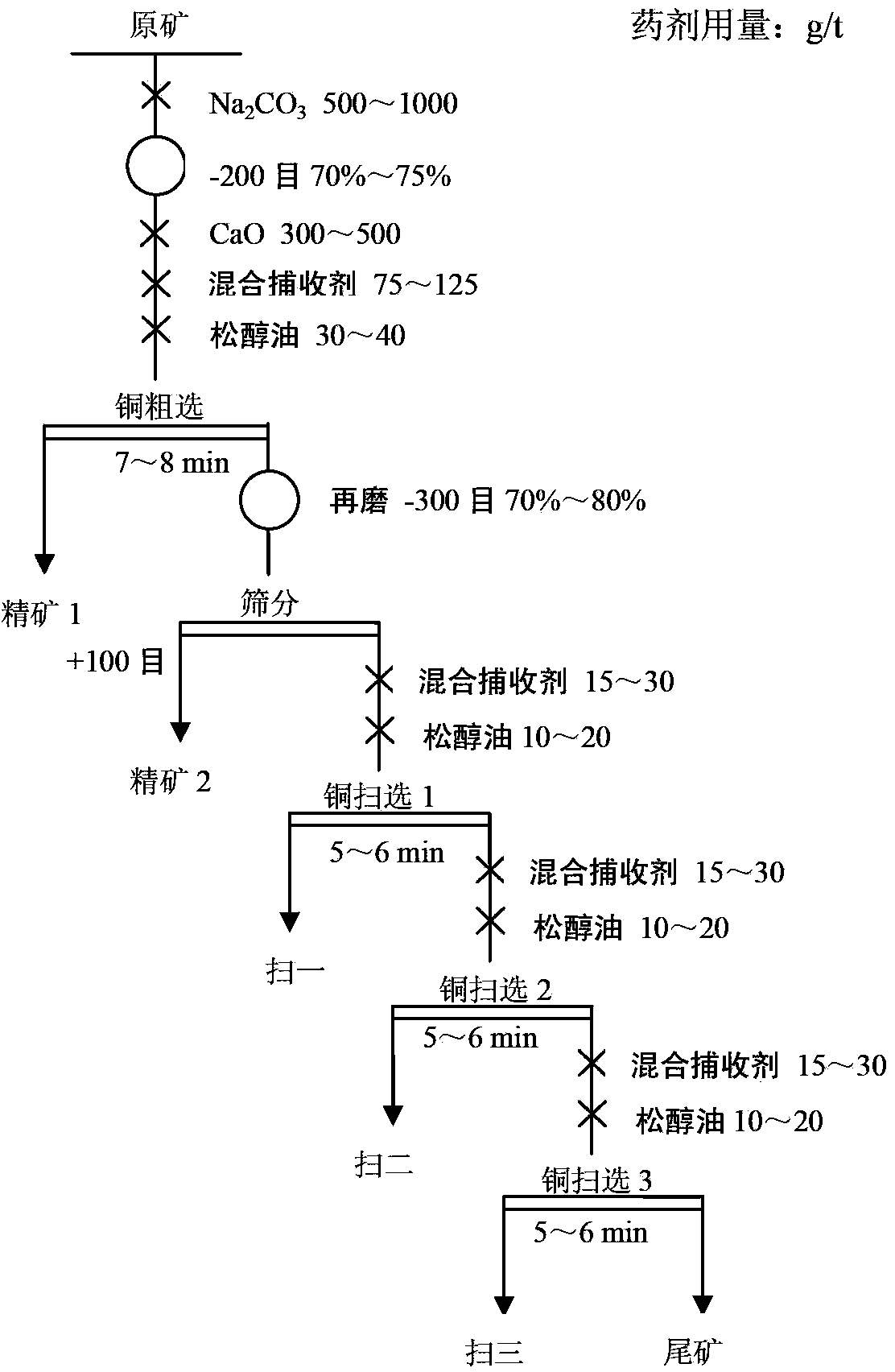

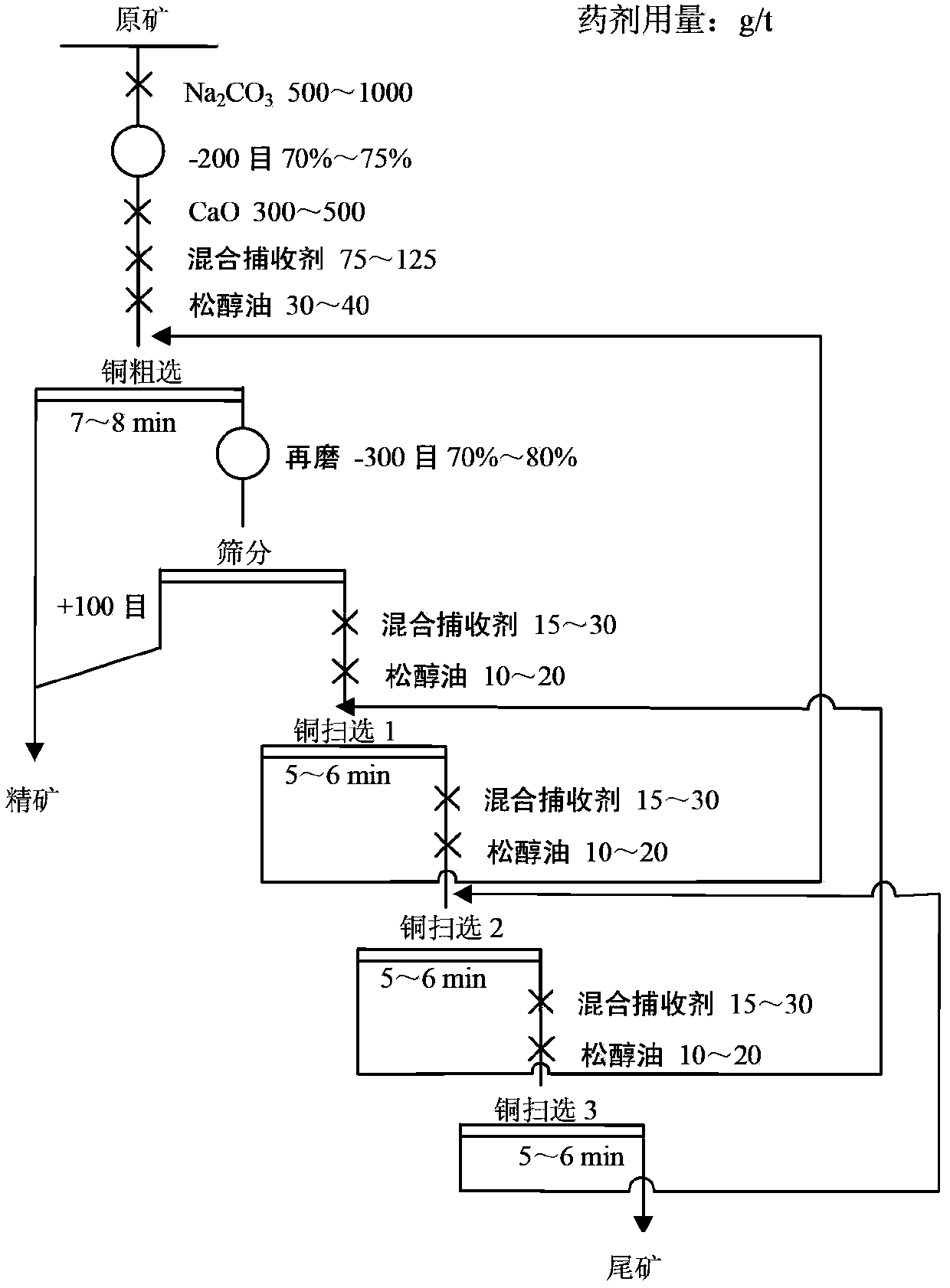

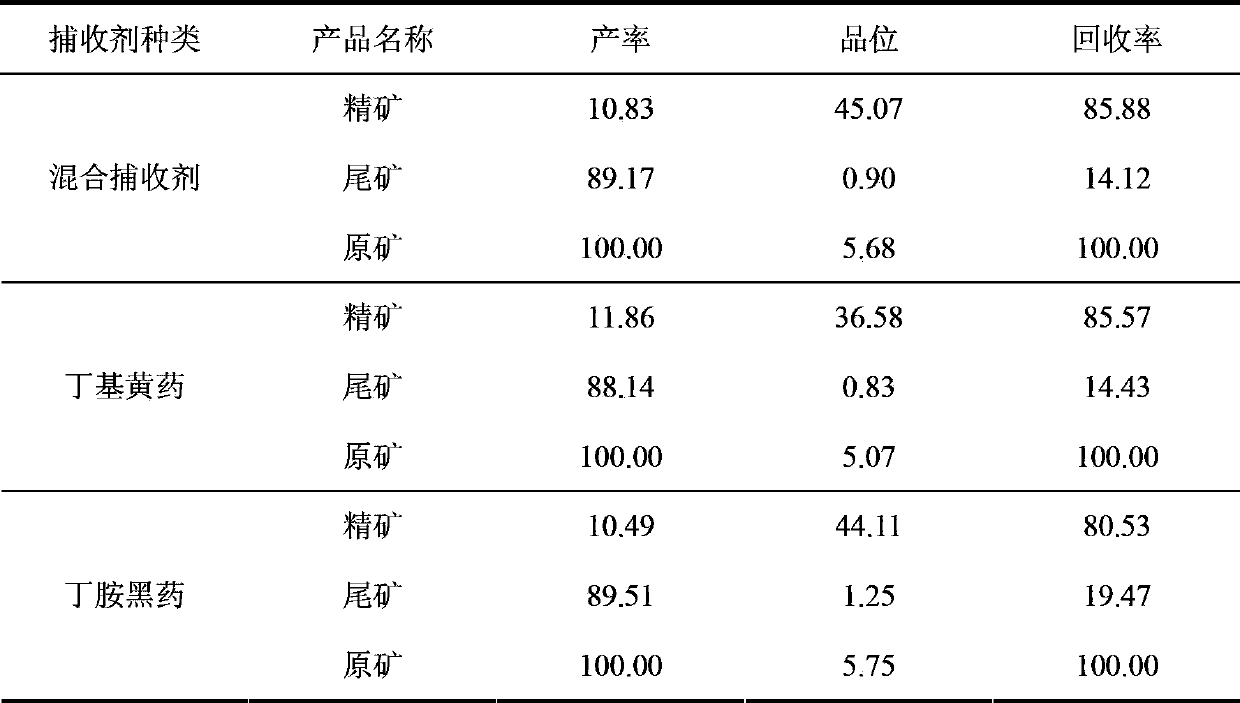

The invention discloses a collecting agent for copper converter slag flotation and a use method thereof. The collecting agent is a mixture prepared from butyl xanthate, butyl amine black powder and xanthate type collecting agent Y89-4 in a mass ratio of (1:1:1)-(3:2:2). When the collecting agent is used, 500-1000g / t of sodium carbonate is added in the first section of copper converter slag grinding process; after the grinding is finished, 300-500g / t of lime is added; the ore pulp pH is adjusted to 10-11; 75-125g / t of the mixed collecting agent and 30-40g / t of foaming agent terpenic oil are further added and stirred and subjected to rough selection; after the rough selection, flotation tailings are subjected to further grinding and screening; screened products are subjected to three times of scavenging; 15-30g / t of mixed collecting agent and 10-20g / t of foaming agent terpenic oil are added for each scavenging. By adopting the technical scheme provided by the invention to process copper converter slag of which cooper content is 5.54 percent, copper concentrate of which the copper grade is 36.26 percent and the recovery rate is 94.82 percent can be obtained through a small-sized closed circuit test, and the copper grade of the floatation tailing is 0.35 percent, so that the recovery index is effectively improved; and meanwhile compared with an ordinary agent, the combined agent has the advantages of low dosage, good index, less pollution and the like.

Owner:CENT SOUTH UNIV

Blast-furnace slag powder and blast-furnace slag and coal cinder compound powder excitant

A trigger for stimulating the early-phase activity of the blast furnace slag powder or the mixture of blast furnace slag powder and cinder powder is proportionally prepared from triethanolamine and early strengthening agent (calcined gypsum or bihydrated gypsum or potassium chromium sulfate).

Owner:SOUTH CHINA UNIV OF TECH

Method for producing high-salinity maritime work cement through mineral waste residue waste materials

The invention discloses a method for producing high-salinity maritime work cement through mineral waste residue waste materials. The high-salinity maritime work cement is prepared from, by weight, 30-40 parts of mineral waste residues, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of composite activating agents, 2-4 parts of early strength agents, 0.3-0.5 part of water reducing agents, 0.005-0.007 part of air entraining agents and 0.3-0.5 part of retarder. The method for producing the high-salinity maritime work cement comprises the steps that the mineral waste residue waste materials, the sulphate aluminum clinker, the composite activating agents and the early strength agents are smashed, ground into powder and homogenized respectively and then dosed, mixed and homogenized according to proportions, then the water reducing agents, the air entraining agents and the retarder are added, mixed and homogenized, and the product is obtained. The high-salinity maritime work cement has the performance of common cement, further has the excellent characters of early-stage hardness resisting, long-term corrosion resistance, retardation progressive increasing and the like, and is especially suitable for ports, wharfs and other engineering which are corroded by corrosive media.

Owner:广西云燕特种水泥建材有限公司

High-efficiency ceramic water reducing agent

InactiveCN104163636AHigh water reducing and dispersing effectReduce usageAmmonium polyphosphatePolypropylene

The invention discloses a high-efficiency ceramic water reducing agent. The high-efficiency ceramic water reducing agent is characterized by comprising the following substances by weight: 15 to 37 parts of hydroxyethyl cellulose, 10 to 38 parts of low molecular polyethylene wax, 1 to 9 parts of vinyl bisstearamide, 3 to 11 parts of alumina, 5 to 17 parts of silica, 24 to 44 parts of ethylene-vinyl acetate copolymer, 3.5 to 17.8 parts of zinc oxide, 15 to 39 parts of a persulfate solution, 31 to 49 parts of polymethylmethacrylate, 1 to 21 parts of ammonium polyphosphate, 2 to 8 parts of polypropylene ester and 11 to 26 parts of titanate. The high-efficiency ceramic water reducing agent provided by the invention has higher water reducing and dispersing effects, exerts a certain grinding assisting effect on ceramic clay, performs an obvious reinforcing effect on a ceramic biscuit, can reduce the usage amount of a grinding aid and a reinforcing agent in the preparation process of ceramics, uses cheap and easily available monomers and easily realizes industrial production.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Ceramic water reducing agent with good dispersion effect

The invention discloses a ceramic water reducing agent with a good dispersion effect. The ceramic water reducing agent with the good dispersion effect is characterized by comprising, by weight, 11 to 28 parts of magnesium carbonate, 5 to 17 parts of hydroxyethyl cellulose, 20 to 34 parts of low molecular polyethylene wax, 10.6 to 35.4 parts of ammonium ferrous sulfate, 15 to 47 parts of calcite, 5 to 61 parts of magnesite, 1 to 7 parts of polypropylene ester, 1.5 to 7.8 parts of barium carbonate, 10 to 20 parts of zirconium silicate, 15 to 34 parts of diboron trioxide, 1 to 8 parts of reactive resin adhesives, 10 to 30 parts of talc, 3 to 7 parts of ammonium polyphosphate and 10 to 50 parts of titanate esters. The ceramic water reducing agent has better water reduction and dispersion effects, has a certain grind-aiding effect on ceramic clay materials and has an obvious enhancing effect on ceramic biscuits, using amount of grinding aid agents and reinforcing agents can be reduced in a ceramic preparing process, a monomer is low in price and easy to obtain, and industrial production is easy to achieve.

Owner:QINGDAO XIANGHAI ELECTRONICS

Production technology for bauxite homogenized-material mud blank

The invention belongs to the technical field of refractory material production, and particularly relates to a production technology for bauxite homogenized-material mud blanks. The production technology includes the steps as follows: (1) breaking bauxite raw ore and deironing to obtain a material A; (2) adding aluminium polychlorid, lignocellulose and water in the material A, conducting ball-milling to obtain a mud material B; and (3) dewatering the mud material B so as to form bauxite homogenized-material mud blank. Due to the common action of the aluminium polychlorid and the lignocellulose, the bauxite homogenized-material mud blank obtains high plasticity and high strength and avoids deformation, cracking and dropping.

Owner:SANMENXIA XINYANGSHAO SYNTHETIC MATERIALS

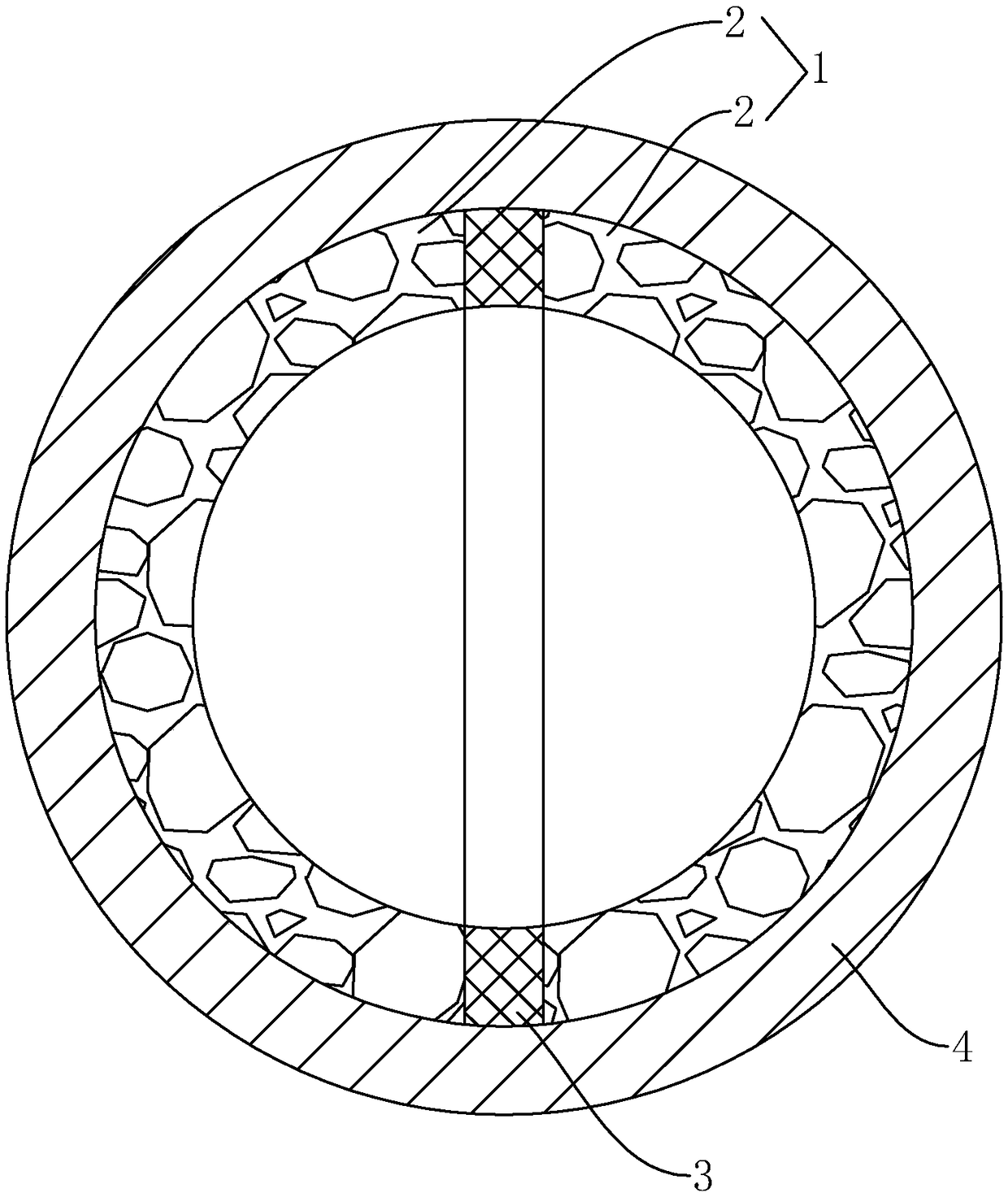

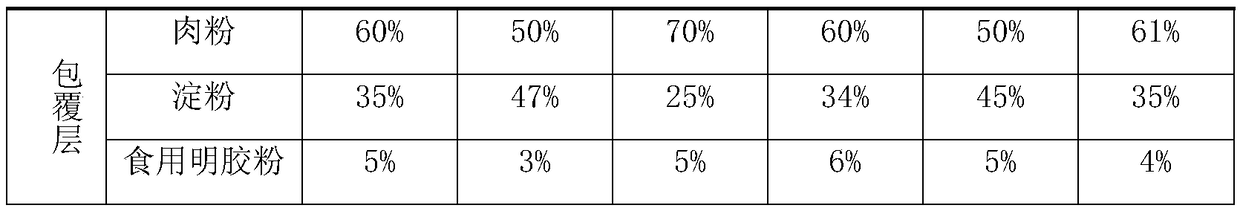

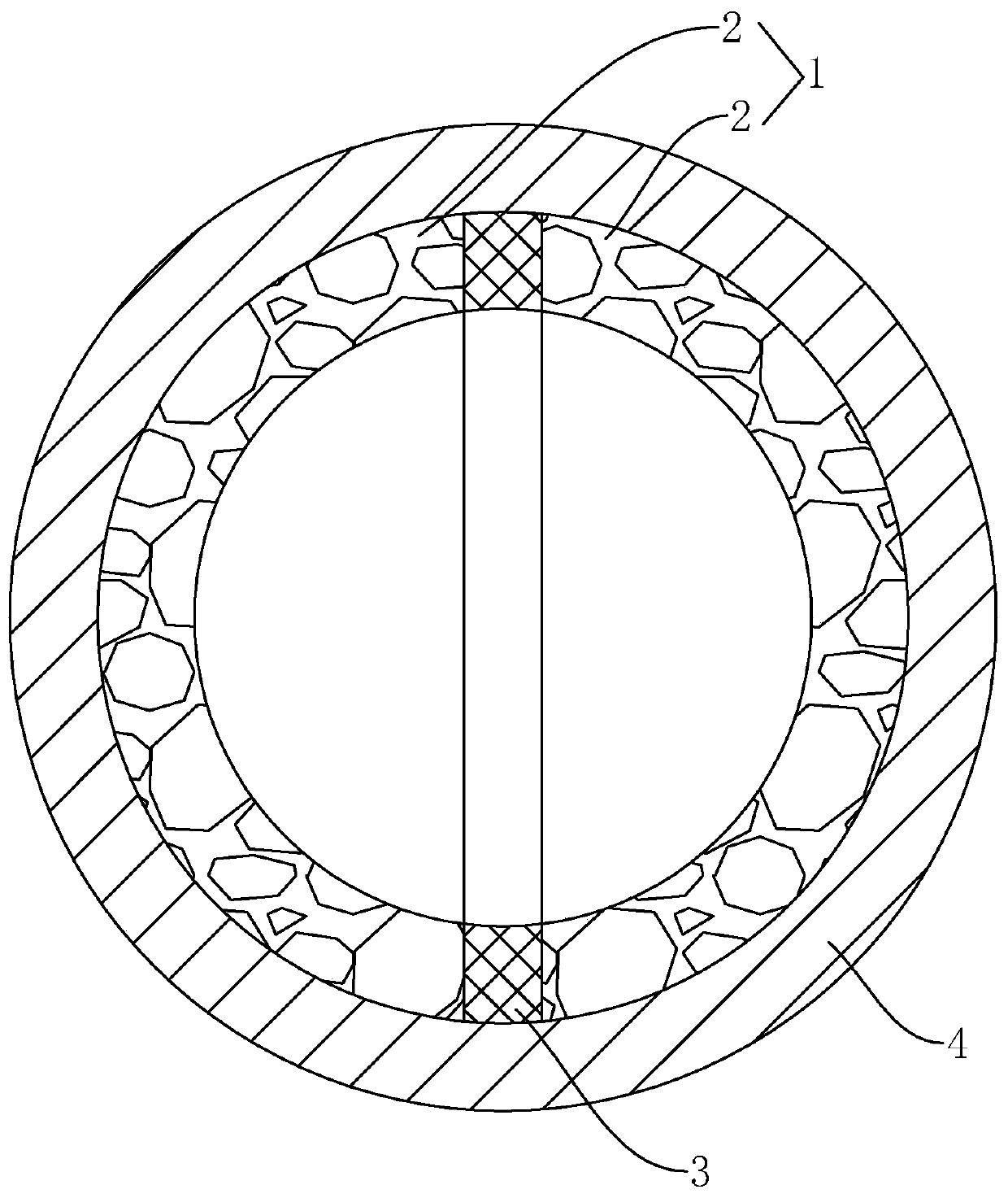

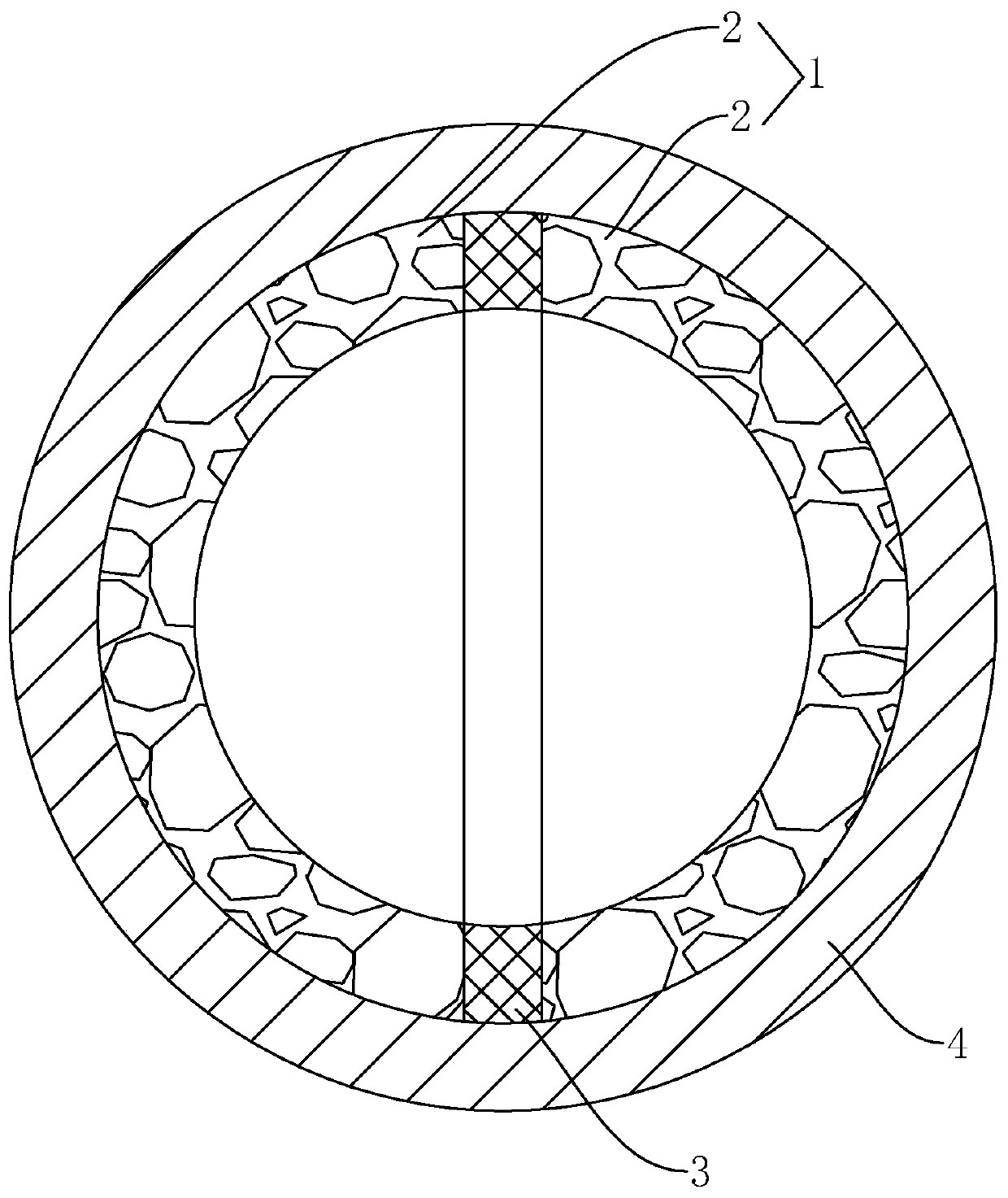

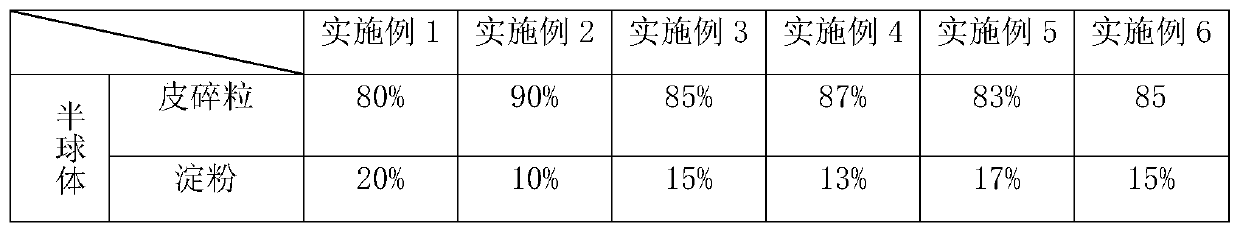

Spherical dog chew and preparation method thereof

ActiveCN108849605AEasy to dryExtended shelf lifeAnimal feeding stuffAccessory food factorsEngineeringTeeth grinding

The invention discloses a spherical dog chew and a preparation method thereof, and belongs to the field of pet foods. The spherical dog chew comprises a hollow ball body, the ball body comprises two hemispheres, the outer side walls of the two hemispheres are wrapped with an elastic coating layer, and the two hemispheres are sealed in the coating layer. The dog chew has the advantages that the ball body of a hollow spherical structure enables the dog chew to have better elasticity, the hollow structure of the ball body is achieved by the splicing of the two hemispheres, which can effectively reduce the processing difficulty and cost, and the elastic coating layer further enhances the flexibility of the dog chew and improves playability. The spherical dog chew has higher attraction to dogs,and has a better interaction function of human and pets, and the dog chew itself has a teeth grinding effect on the dogs.

Owner:温州致兴宠物营养科技有限公司

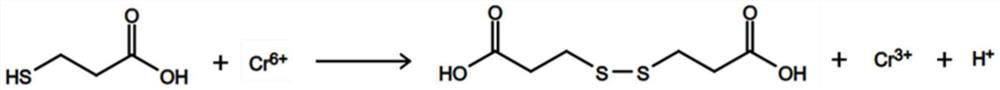

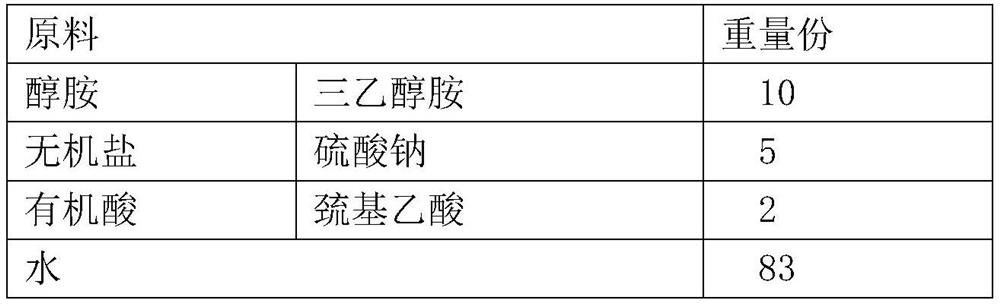

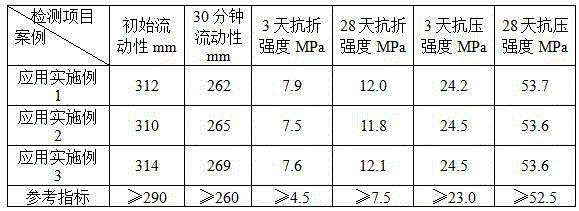

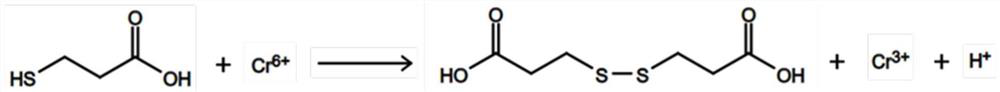

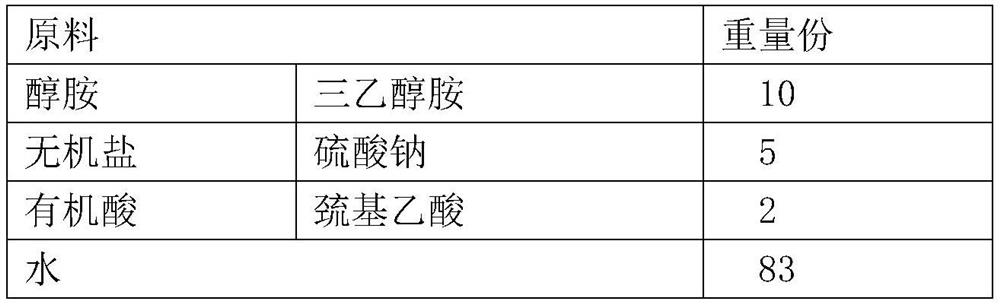

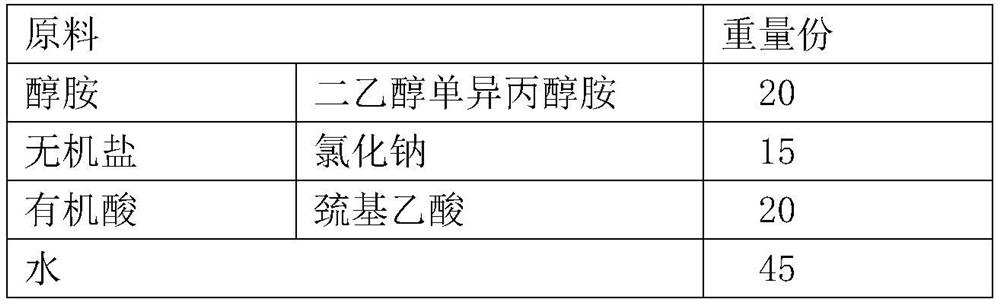

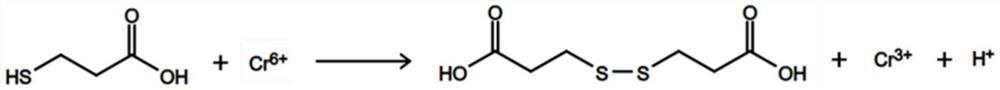

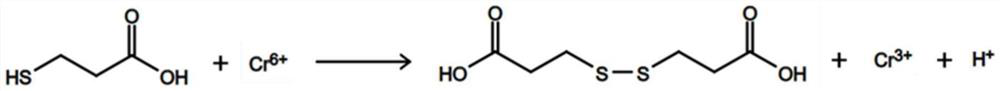

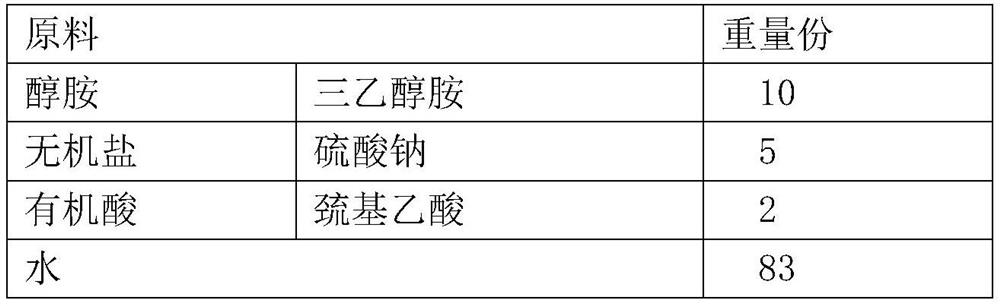

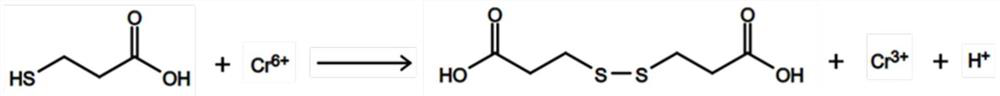

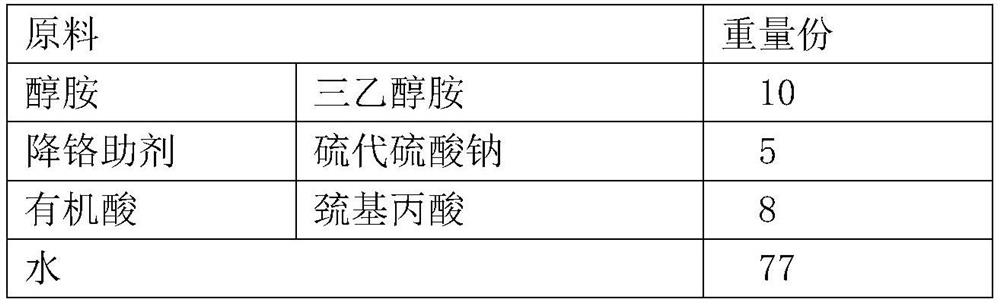

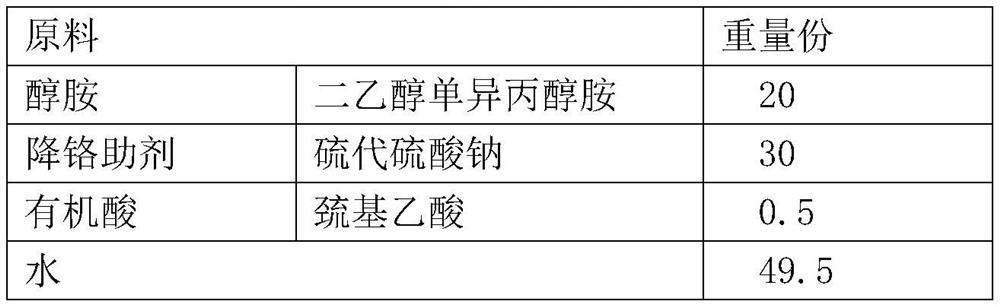

Chromium-reducing cement and preparation method thereof

ActiveCN111635150AImprove high temperature oxidation resistanceHigh temperature oxidation resistanceInorganic saltsOrganic acid

The invention provides chromium-reducing cement and a preparation method thereof, and solves the technical problems that in the prior art, ferrous sulfate and chromium-reducing cement are exposed in air, so that the chromium-reducing effect is influenced and the requirement on the use temperature is strict as the ferrous sulfate and the chromium-reducing cement are both gradually oxidized. The chromium-reducing cement comprises the following steps: by weight, 10-20 parts of alkylol amine, 5-15 parts of an inorganic salt, 2-20 parts of an organic acid and 45-83 parts of water. Due to the addition of a chromium-reducing grinding aid, the chromium-reducing grinding aid not only has the grinding aid effect of the grinding aid, but also has strong oxidation resistance, is suitable for long-termstorage, and can prevent the chromium-reducing effect from being influenced by oxidation during storage. A finished product is a uniform solution, so that pump blockage caused by precipitation accumulation can be avoided, the high-temperature-resistant performance is excellent, and the cement working condition temperature change can be well adapted. The production process is simple, operation andquality control are easy, and obvious technical advantages and wide market prospects are achieved.

Owner:ANHUI CONCH GRP +3

Blast-furnace slag powder and blast-furnace slag and coal cinder compound powder excitant

A trigger for stimulating the early-phase activity of the blast furnace slag powder or the mixture of blast furnace slag powder and cinder powder is proportionally prepared from triethanolamine and early strengthening agent (calcined gypsum or bihydrated gypsum or potassium chromium sulfate).

Owner:SOUTH CHINA UNIV OF TECH

Special collision-resistance and modification microcrystalline ceramic abrasive material for machine tool industry, and manufacturing method thereof

ActiveCN110104974AHas a soft elastic effectLubriciousOther chemical processesSilicic acidUnsaturated monomer

The invention discloses a special collision-resistance and modification microcrystalline ceramic abrasive material for machine tool industry, and a manufacturing method thereof. The microcrystalline ceramic abrasive material comprises two parts, wherein the first part is a microcrystalline ceramic formed by sintering alumina powder, lanthanum nitrate hexahydrate and hydroxyapatite in a shuttle kiln, the second part is obtained by polymerizing three components A, B and C, the component A is a mixture of a vinyl olefin-based unsaturated monomer, a phosphorus bidentate ligand, lead powder, activecarbon powder and titanium dioxide powder, the component B is an acrylate-based olefin-based unsaturated monomer, the component C is a sodium silicate aqueous solution with a solute mass fraction of10%, and the second part is a microcapsule structure using the lead powder, the active carbon powder and the titanium dioxide powder as a core, using a silicic acid gel as a medium, and using the vinyl olefin-based unsaturated monomer and acrylate-based olefin-based unsaturated monomer polymer as a mold shell. According to the present invention, the special collision-resistance and modification microcrystalline ceramic abrasive material has characteristics of microcrystalline structure, fine and dense grinding blade, high strength, good toughness, self-loss resistance and durability.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

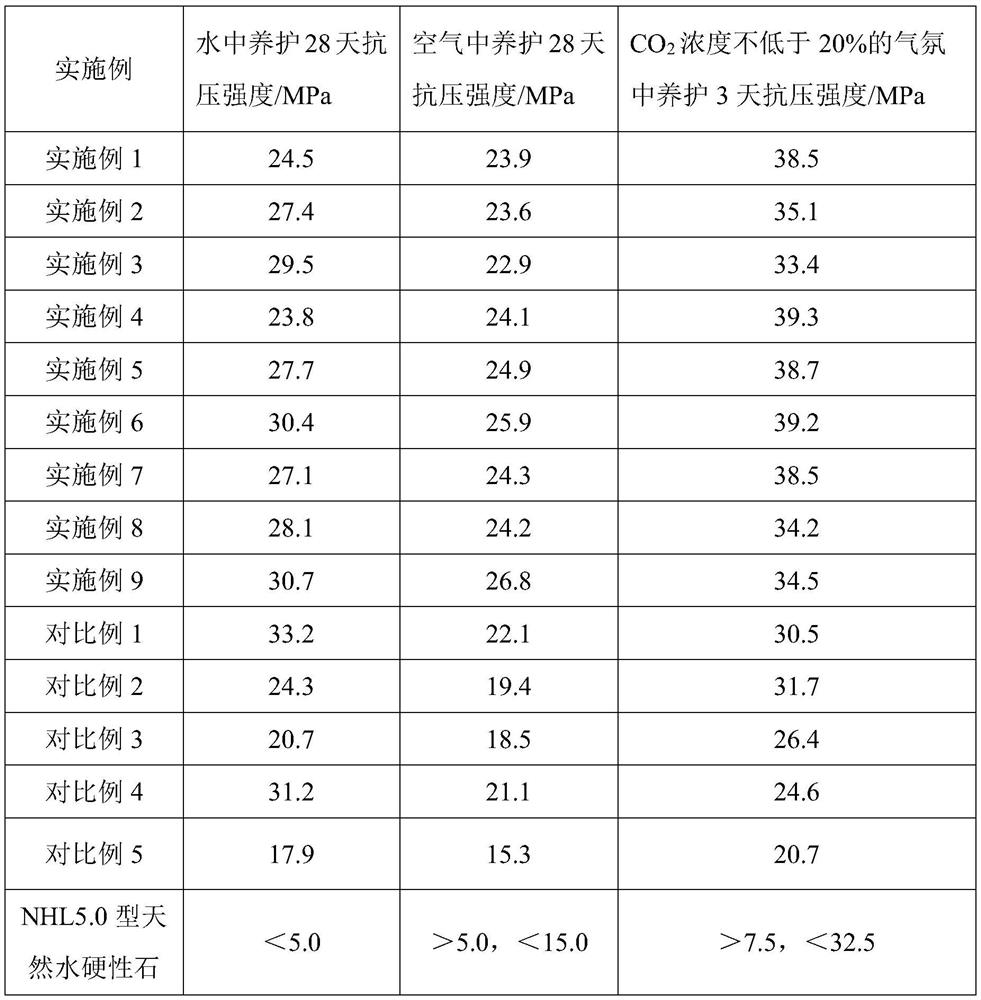

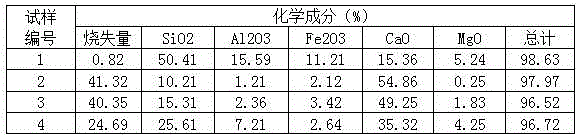

Hydrated and carbonized composite hardened cementing material based on steel slag and preparation method of hydrated and carbonized composite hardened cementing material

The invention discloses a hydrated and carbonized composite hardened cementing material based on steel slag and a preparation method thereof, belongs to the technical field of building materials, and solves the problems of high consumption, high energy consumption, large CO2 emission, low carbonized and hardened body strength and narrow application range in production of natural ore from hydraulic lime / natural hydraulic lime. The hydrated and carbonized composite hardened cementing material based on steel slag comprises the following raw materials: 25-30% of cement clinker, 20-25% of pretreated carbide slag, 1.5-2.0% of industrial byproduct gypsum, 3-5% of bentonite, 0.5-1.0% of a hydrated and carbonized accelerant and the balance of steel slag. The method comprises the following steps: preparing materials, selecting iron, and grinding into powder. The hydration and carbonization composite hardening cementing material based on the steel slag has good hydration hardening performance and carbonization hardening performance, a hardened body shows good mechanical performance in water, air and CO2 atmosphere, and the application field is widened.

Owner:JIAHUA SPECIAL CEMENT +1

Method for producing green ecological cement resistant to seawater corrosion with stone waste

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste, which comprises the following raw materials in parts by weight: 30-40 parts of stone waste; 40-50 parts of sulphoaluminate cement clinker; 0.03-0.05 parts of activator; 2-4 parts of early strength agent; 0.3-0.5 parts of water reducing agent; 0.005-0.007 parts of air-entraining agent; The salt cement clinker, composite activator and early strength agent are crushed separately, pulverized, homogenized, then mixed and homogenized according to the proportion, and then added with water reducer, air-entraining agent and retarder, mixed and homogenized to obtain the product. The seawater corrosion-resistant green ecological cement of the present invention, in addition to the performance of ordinary cement, also has excellent characteristics such as high strength, seawater erosion resistance, seawater erosion resistance, etc., and is especially suitable for underground projects, ports, wharves and other erosive media. project.

Owner:广西云燕特种水泥建材有限公司

A kind of reduced chromium type cement grinding aid and preparation method thereof

ActiveCN111517687BHas a grinding effectImprove high temperature oxidation resistanceInorganic saltsOrganic acid

Owner:安徽海螺材料科技股份有限公司 +1

A kind of reduced chromium type cement and preparation method thereof

ActiveCN111635150BImprove high temperature oxidation resistanceHigh temperature oxidation resistanceInorganic saltsOrganic acid

The invention provides a reduced-chromium cement and a preparation method thereof, which solves the problem of ferrous sulfate and reduced-chromium cement in the prior art. Due to exposure to air, both ferrous sulfate and reduced-chromium cement will be gradually oxidized , which in turn affects the chromium reduction effect, and there is a technical problem of strict requirements on the use temperature. Its preparation comprises the following components by weight: 10-20 parts of alcohol amine; 5-15 parts of inorganic salt; 2-20 parts of organic acid; 45-83 parts of water. Due to the addition of chromium-reducing grinding aid in the present invention, it not only has the grinding-aiding effect of the grinding aid itself, but also has strong oxidation resistance, is suitable for long-term storage, and can avoid storage being oxidized and affecting the chromium-reducing effect; the finished product is uniform solution, which can avoid the phenomenon of sediment accumulation and easy pump blockage; and has excellent high temperature resistance, which can well adapt to the temperature change of cement working conditions; the production process is simple, easy to operate and quality control, and has obvious technical advantages and a broad market prospect.

Owner:ANHUI CONCH GRP +3

Grinding aid for gold ore grinding with leaching assisting effect and preparation method therefor

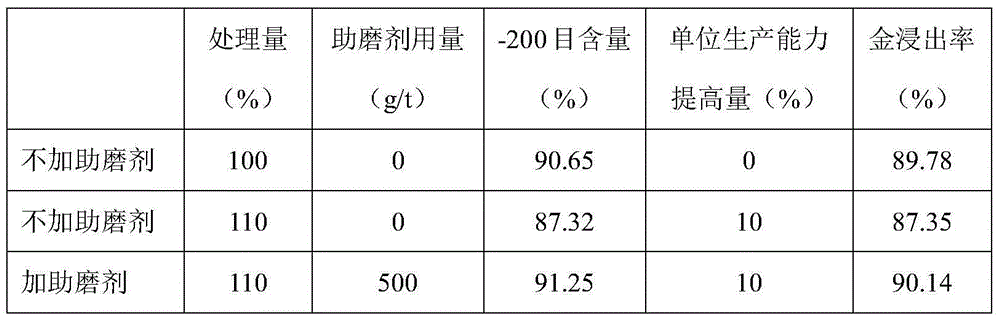

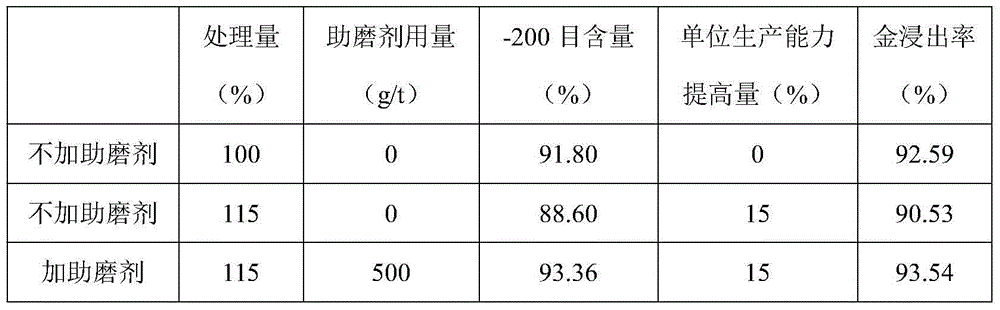

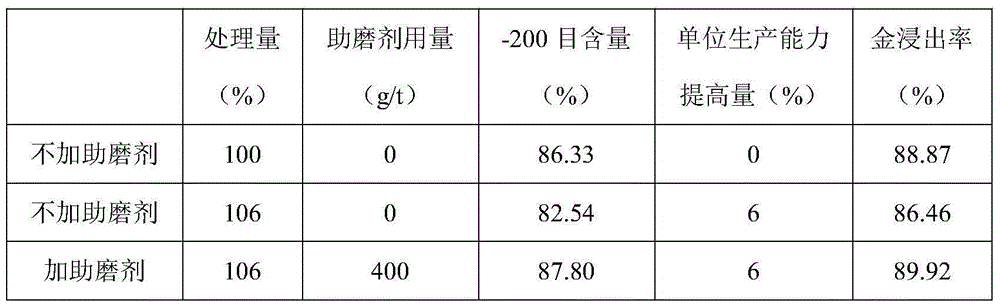

ActiveCN105733505AIncrease throughputImprove grinding effectOther chemical processesProcess efficiency improvementGold oreBall mill

The invention relates to a grinding aid for gold ore grinding with a leaching assisting effect. The grinding aid is prepared from the ingredients in percentage by weight: 10% to 20% of CaO2, 20% to 30% of NaCl, 20% to 30% of sodium tripolyphosphate and 20% to 30% of sodium humate, wherein the sum of weight percent of all the ingredients is 100%. The grinding aid is prepared through uniformly mixing all the ingredients proportionally. The grinding aid has the advantages that the use level is low, the grinding assisting effect is good, the grinding aid plays a role in helping the leaching of gold and is directly added from an inlet of a ball mill in the form of solid, and the operation is simple.

Owner:HENAN GREEN GOLD MINING TECH CO LTD

Preparation method of activated grinding aid for concrete composite admixture

ActiveCN113354330BImprove grinding efficiencyReduce limit finenessPolyacrylamideUltrasonic generator

The invention provides a preparation method of an activated grinding aid for concrete composite admixture, comprising: pretreating polyacrylamide to obtain 3 + cationic polyacrylamide solution; add the K12 solution with a mass concentration of 8~12% to the cationic polyacrylamide solution at a constant speed, and at the same time, use an ultrasonic generator with a power of 200~500W and a frequency of 40~120kHz , heated to 60°C and stirred at a constant temperature for 1-2 hours; after the dropwise addition was completed, turn off the ultrasonic generator, stop stirring, and lower the temperature to 50°C for 1-2 hours; put the solution obtained after ultrasonication in a vacuum drying oven, without The activated grinding aid for the concrete composite admixture is obtained by evaporating, drying and concentrating at a temperature exceeding 50°C. The grinding aid prepared by the method of the invention can slowly release K12 molecules during the grinding process to continuously produce the grinding aiding effect, thereby greatly improving the grinding efficiency.

Owner:HUNAN UNIV +1

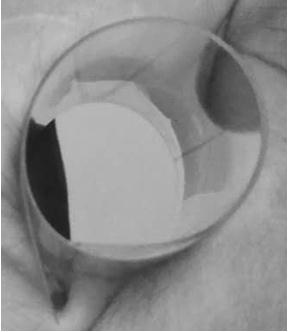

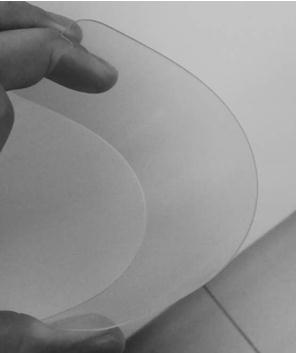

A kind of preparation method of ultra-thin glass

The invention relates to the technical field of glass, in particular to a preparation method of ultra-thin glass, comprising the following steps: (1) taking glass, soaking the glass in a thinning etchant, and performing the first thinning treatment on the glass; (2) The thinned glass is double-sided grinding and polishing; (3) The double-sided grinding and polishing glass is attached to the carrier glass, and then soaked in the thinning etchant, and the glass is subjected to the second thinning treatment to make Get ultra-thin glass. The ultra-thin glass preparation method of the present invention can prepare ultra-thin glass with thin thickness, strong light transmission, good softness, and high touch sensitivity. It is used to prepare ultra-thin glass with a thickness of 0.03mm.

Owner:东莞市嘉逸光电有限公司

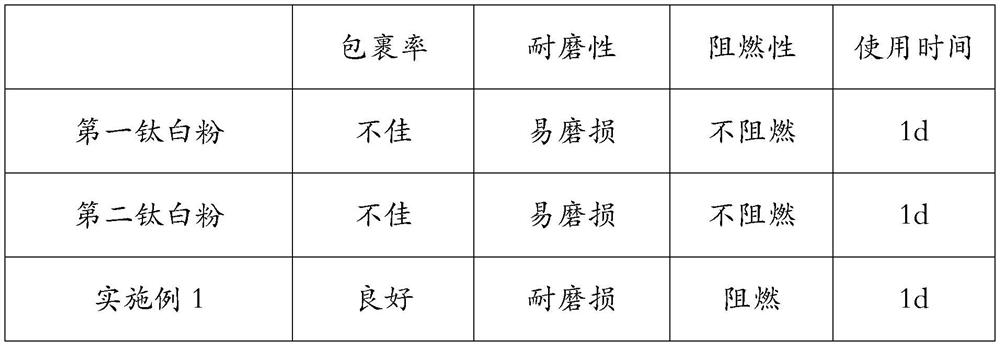

Novel nanoscale liquid titanium dioxide for coating

InactiveCN112175417AHas a grinding effectIncrease coverageFireproof paintsNanotechnologyMaterials scienceDioxide titanium

The invention provides novel nanoscale liquid titanium dioxide for a coating, and relates to the technical field of titanium dioxide, and the novel nanoscale liquid titanium dioxide for the coating comprises the following raw materials in parts by weight: 60-80 parts of titanium dioxide particles, 100-120 parts of calcium carbonate powder, 50-70 parts of wear-resistant and acid-resistant powder, 660-880 parts of deionized water, 6-16 parts of an activating agent and 8-20 parts of a flame retardant. According to the novel nanoscale liquid titanium dioxide for papermaking, the coating rate of titanium dioxide powder to calcium carbonate nano-powder can be increased, the used calcium carbonate powder and titanium dioxide powder are both ground to be nanoscale, the coating effect can be further guaranteed, wear-resistant and acid-resistant powder is added in the preparation process, the prepared nanoscale liquid titanium dioxide has a good wear-resisting effect after being used, and meanwhile, the added flame retardant enables the nanoscale liquid titanium dioxide to have flame retardance after being used so that the liquid titanium dioxide with excellent quality is prepared.

Owner:许荣

Novel high-efficiency ceramic water reducer

The invention discloses a novel high-efficiency ceramic water reducer which is characterized by comprising the following substances in parts by weight: 25-67 parts of polymethacrylic acid vinegar, 5-23 parts of hydroxyethyl cellulose, 15-20 parts of low-molecular polyethylene wax, 14-27 parts of sodium methylallyl sulfonate, 5-11 parts of glacial acetic acid, 10-32 parts of sodium hydroxide, 15-19.4 parts of sodium hypophosphite, 1-19 parts of persulfate solution, 3-21 parts of ammonium polyphosphate, 1-6 parts of polypropenyl ester, 0-8 parts of vinyl bis stearamide and 1-8 parts of titanate. The novel high-efficiency ceramic water reducer has higher water reduction and dispersion effects, and has certain grinding assisting action on the ceramic earth material; the ceramic biscuit has obvious reinforcing effect, and can reduce the consumption of the grinding aid and reinforcer in the ceramic preparation process; and the novel high-efficiency ceramic water reducer is cheap and accessible in monomers, and can easily implement industrial production.

Owner:QINGDAO XIANGHAI ELECTRONICS

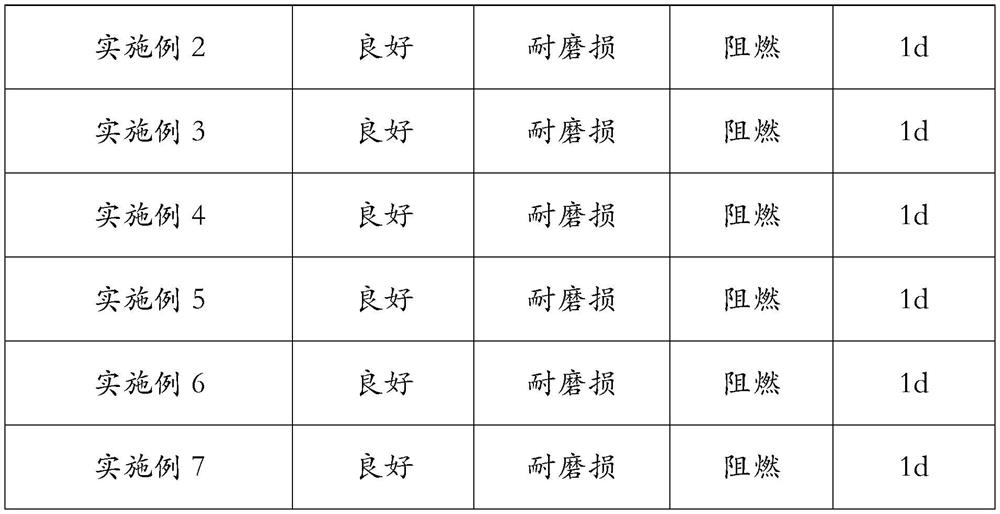

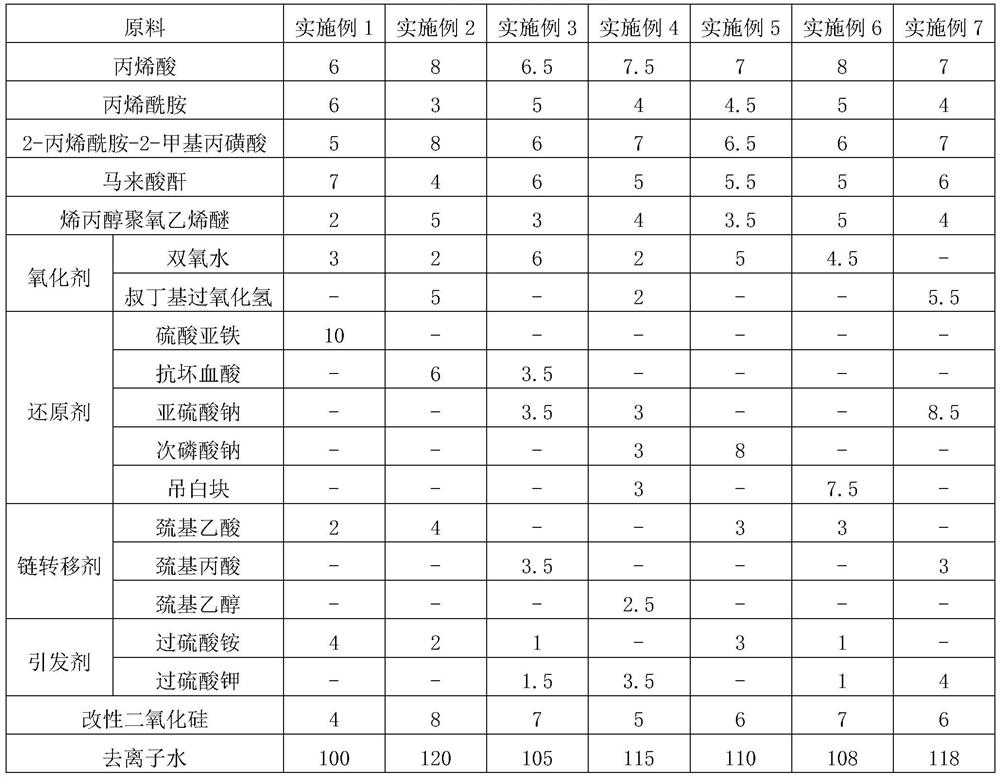

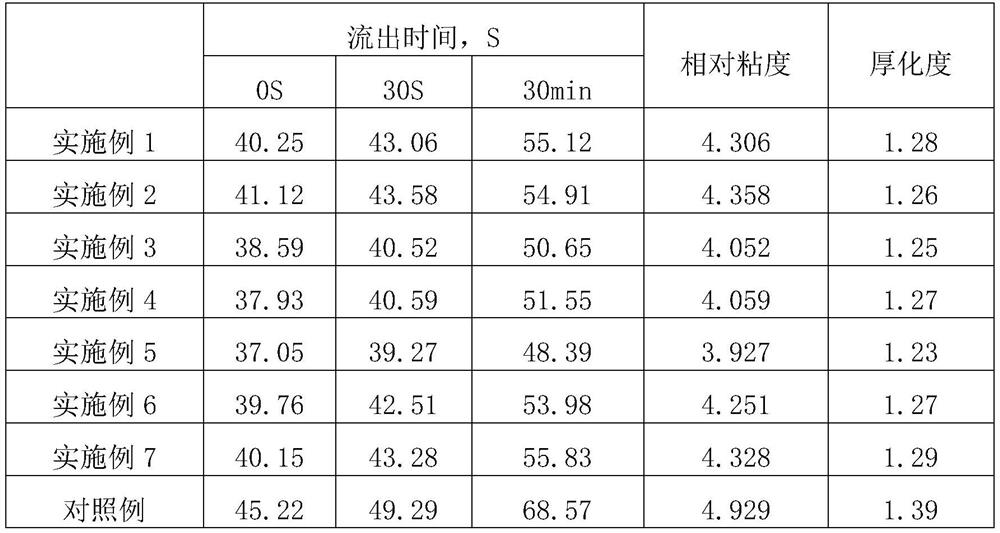

Polycarboxylate superplasticizer for ceramics and preparation method thereof

The invention discloses a polycarboxylic acid water reducing agent for ceramics and a preparation method thereof, and solves the technical problems that when a water reducing agent in the prior art is applied to the ceramic industry, the water reducing rate is relatively low, the reducing effect is general, and the energy consumption is relatively high when a spray drying tower is used for drying. The water reducer is prepared from the following raw materials in parts by weight: 6-8 parts of acrylic acid; 3 to 6 parts of acrylamide; 5 to 8 parts of 2-acrylamide-2-methylpropanesulfonic acid; 4-7 parts of maleic anhydride; 2 to 5 parts of allyl alcohol polyoxyethylene ether; 3-7 parts of an oxidant; 6-10 parts of a reducing agent; 2-4 parts of a chain transfer agent; 2-4 parts of an initiator; 4-8 parts of modified silicon dioxide; and 100 to 120 parts of deionized water. When the water reducing agent is applied to the ceramic industry, the water reducing rate is high, the dispersion effect of ceramic slurry is good, and the energy consumption of a spray drying tower during drying is greatly reduced.

Owner:SICHUAN SEDAR CHEM

A kind of production method of marine cement block

The invention discloses a production method of a marine engineering cement block. The marine engineering cement block comprises the following raw materials in parts by weight: 30-80 parts of slag, 10-50 parts of a sulphoaluminate cement clinker, 0.03-0.05 part of an accelerating activating admixture, 2-4 parts of an early strength agent, 0.3-0.5 part of a water reducing agent, 0.005-0.007 part of an air entraining agent and 0.3-0.5 part of a retarder. The production method comprises the following steps: respectively crushing, milling and homogenizing the slag waste, the sulphoaluminate cement clinker, the accelerating activating admixture and the early strength agent; and mixing and homogenizing ingredients at the ratio, adding the water reducing agent, the air entraining agent and the retarder for mixing, homogenizing and molding to obtain the product. The marine engineering cement block disclosed by the invention also has excellent characteristics of high strength, seawater washing resistance, early hardening resistance, long-term erosion resistance and the like besides of properties of an ordinary cement block, and is especially suitable for ports, wharfs and other erosion medium-corroded engineering.

Owner:广西云燕特种水泥建材有限公司

Method for producing green ecological cement resistant to seawater corrosion with lime plant waste

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using wastes from lime factories. The cement comprises the following raw materials in parts by weight: 45-55 parts of wastes from lime factories, 40-50 parts of sulphoaluminate cement clinkers, 0.04-0.07 part of compound activating agent, 1-3 parts of early strength agent, 0.5-0.7 part of water reducing agent, 0.004-0.006 part of air entraining agent and 0.4-0.6 part of retarder. The production method is characterized by breaking, grinding and homogenizing the wastes from lime factories, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, then preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Collecting agent for copper converter slag flotation and use method thereof

The invention discloses a collecting agent for copper converter slag flotation and a use method thereof. The collecting agent is a mixture prepared from butyl xanthate, butyl amine black powder and xanthate type collecting agent Y89-4 in a mass ratio of (1:1:1)-(3:2:2). When the collecting agent is used, 500-1000g / t of sodium carbonate is added in the first section of copper converter slag grinding process; after the grinding is finished, 300-500g / t of lime is added; the ore pulp pH is adjusted to 10-11; 75-125g / t of the mixed collecting agent and 30-40g / t of foaming agent terpenic oil are further added and stirred and subjected to rough selection; after the rough selection, flotation tailings are subjected to further grinding and screening; screened products are subjected to three times of scavenging; 15-30g / t of mixed collecting agent and 10-20g / t of foaming agent terpenic oil are added for each scavenging. By adopting the technical scheme provided by the invention to process copper converter slag of which cooper content is 5.54 percent, copper concentrate of which the copper grade is 36.26 percent and the recovery rate is 94.82 percent can be obtained through a small-sized closed circuit test, and the copper grade of the floatation tailing is 0.35 percent, so that the recovery index is effectively improved; and meanwhile compared with an ordinary agent, the combined agent has the advantages of low dosage, good index, less pollution and the like.

Owner:CENT SOUTH UNIV

A kind of compound reducing chromium type cement grinding aid and preparation method thereof

ActiveCN111635160BHas a grinding effectImprove high temperature oxidation resistanceOrganic acidSulfate

The invention provides a composite dechrome cement grinding aid and a preparation method thereof, which solves the problem of ferrous sulfate and chromium depleting cement grinding aids in the prior art. Type cement grinding aids will be gradually oxidized, which will affect the chromium reduction effect, and there is a technical problem of strict requirements on the use temperature. Its preparation comprises the following components by weight: 10-20 parts of alkanolamine; 5-30 parts of chromium-reducing additive; 0.5-8 parts of organic acid; 42-84.5 parts of water. The composite chromium-reducing cement grinding aid prepared by the present invention not only has the grinding aid effect of the grinding aid itself, but also has strong oxidation resistance, is suitable for long-term storage, and can avoid storage being oxidized and affecting the chromium-reducing effect; the finished product is uniform solution, which can avoid the phenomenon of sediment accumulation and easy pump blockage; and has excellent high temperature resistance, which can well adapt to the temperature change of cement working conditions; the production process is simple, easy to operate and quality control, and has obvious technical advantages and a broad market prospect.

Owner:安徽海螺材料科技股份有限公司 +1

Method for producing seawater corrosion-resistant green ecological cement with construction waste

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from construction waste, which comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinker; 5-20 parts of construction waste; steel slag fine powder 20-25 parts; 0.06-0.08 parts of composite activator; 2-5 parts of early strength agent; 0.3-0.5 parts of water reducing agent; 0.005-0.007 parts of air-entraining agent; Construction waste, sulphoaluminate cement clinker, composite activator and early strength agent are crushed separately, milled, homogenized, mixed and homogenized according to the proportion, and then mixed and homogenized by adding water reducing agent, air-entraining agent and retarder get the product. The seawater corrosion-resistant green ecological cement of the present invention, in addition to the performance of ordinary cement, also has excellent characteristics such as high strength, seawater erosion resistance, seawater erosion resistance, etc., and is especially suitable for underground projects, ports, wharves and other erosive media. project.

Owner:广西云燕特种水泥建材有限公司

A kind of spherical dog chew and preparation method thereof

ActiveCN108849605BIncrease elasticityHigh playabilityAnimal feeding stuffAccessory food factorsBiotechnologyChewing Gum (food)

The invention discloses a spherical dog chew and a preparation method thereof, and belongs to the field of pet foods. The spherical dog chew comprises a hollow ball body, the ball body comprises two hemispheres, the outer side walls of the two hemispheres are wrapped with an elastic coating layer, and the two hemispheres are sealed in the coating layer. The dog chew has the advantages that the ball body of a hollow spherical structure enables the dog chew to have better elasticity, the hollow structure of the ball body is achieved by the splicing of the two hemispheres, which can effectively reduce the processing difficulty and cost, and the elastic coating layer further enhances the flexibility of the dog chew and improves playability. The spherical dog chew has higher attraction to dogs,and has a better interaction function of human and pets, and the dog chew itself has a teeth grinding effect on the dogs.

Owner:温州致兴宠物营养科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com