Preparation method of antibacterial straw loaded with silver particles

A technology of silver particles and straw is applied in the field of preparation of antibacterial straw, which can solve the problems of shortening the service life, affecting the living environment, moldy wallboard, etc., and achieving the effects of reducing pollution, easy operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

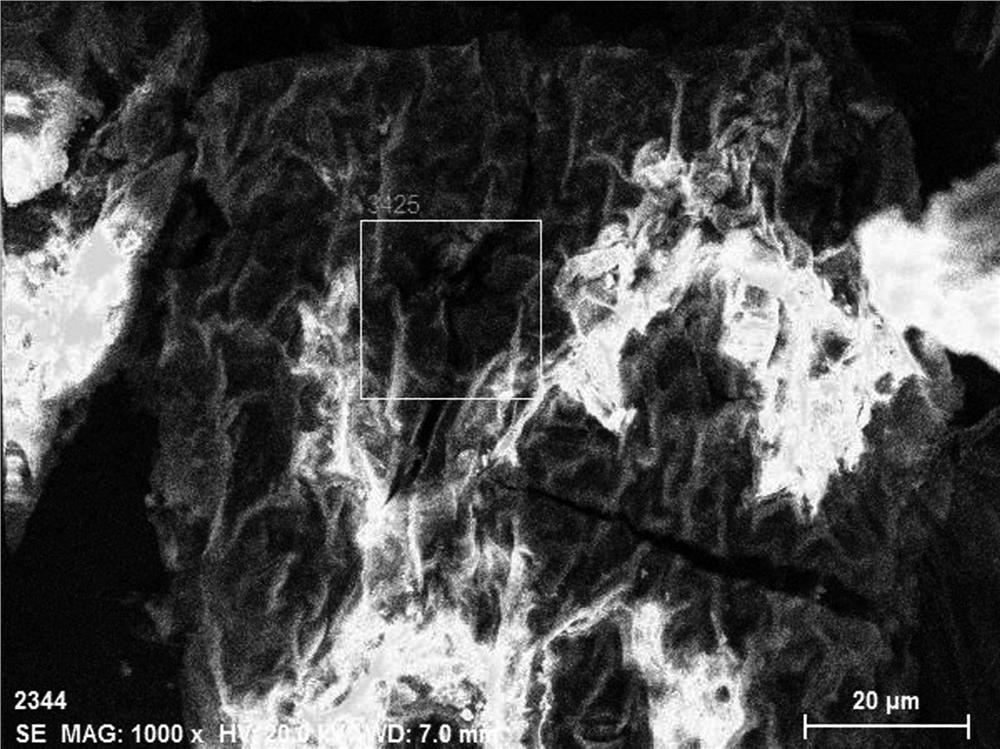

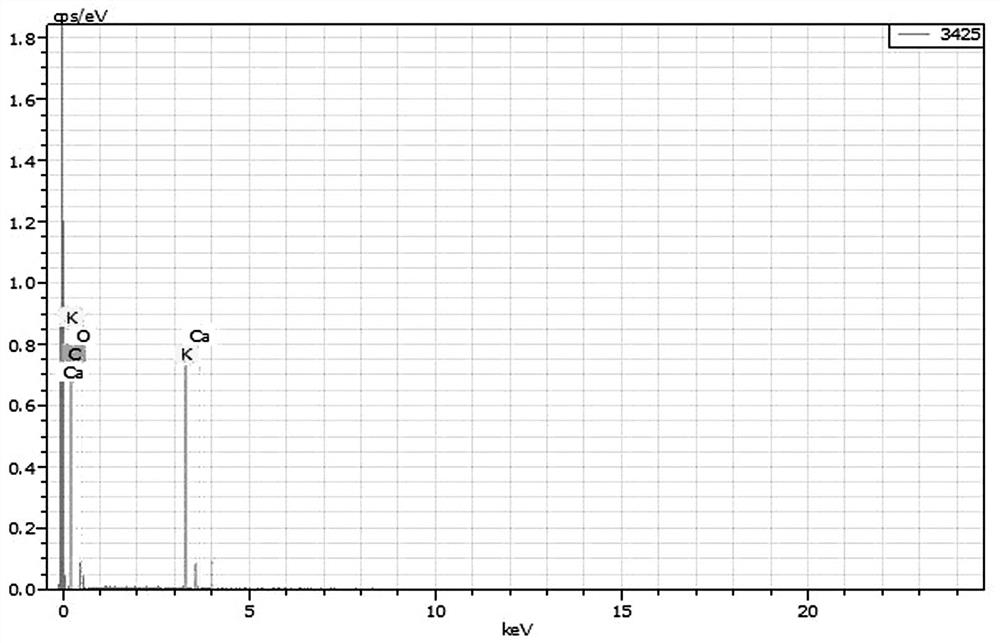

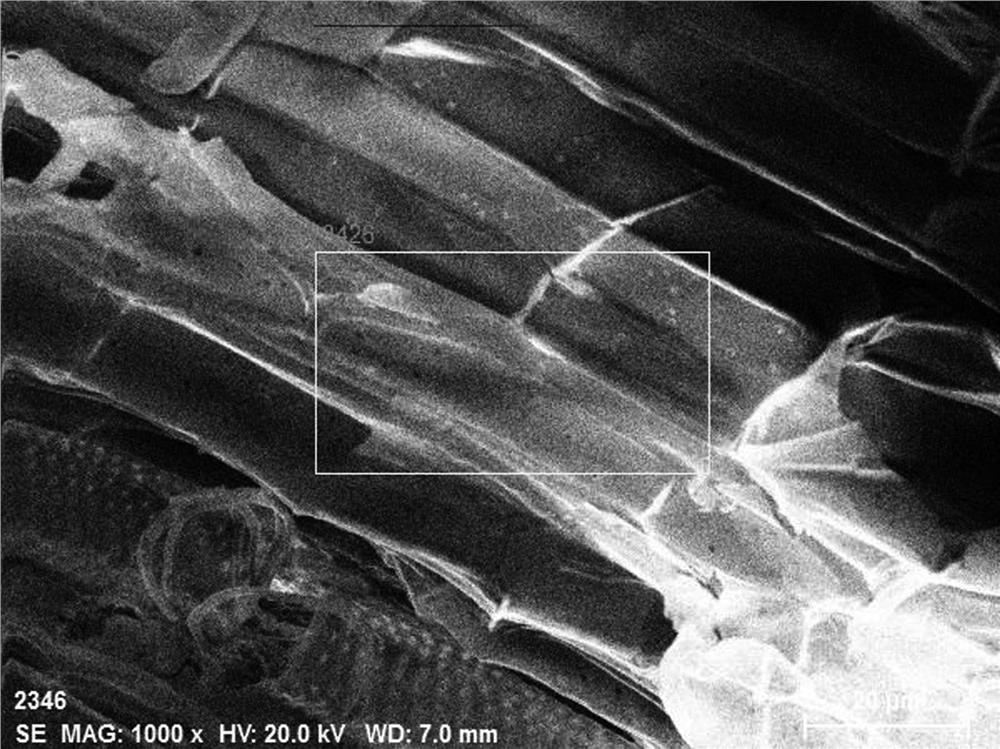

Image

Examples

Embodiment 1

[0045] The present invention relates to a method for preparing antibacterial straw loaded with silver particles, comprising the following steps:

[0046] S1, take the soybean straw, remove the leaves and roots, and then wash, dry and truncate the straw in turn with clean water, sift it with a 20 mesh sieve to obtain a straw greater than 20 mesh, that is, a length of 1cm, and then wash the straw of this length with deionized water and dry it.

[0047] S2, the use of lye to treat the straw: take 1g S1 of the straw obtained soaked in a volume of 10mL, the concentration of 1mol / L naOH solution, through the temperature of 60 °C water bath reflux heating state reaction 3h, and while heating while stirring, and then with deionized water filter washing straw, in the use of volume of 10mL, the concentration of 0.1mol / L hydrochloric acid neutralize and the residual alkali on the surface of the straw, and stand for 15min, filter wash three times, The stalks are separated and dried at a t...

Embodiment 2

[0083] S1, take the rice straw and remove the leaves and roots, and then wash, dry and truncate the straw in turn with clean water, sift it with a 20 mesh sieve to obtain a straw greater than 20 mesh, that is, a length of 1cm, and then wash the straw of this length with deionized water and dry it.

[0084] S2, the use of lye to treat the straw: take 1g S1 of the straw obtained soaked in a volume of 20mL, the concentration of 1mol / L NaOH solution, through the temperature of 80 °C water bath reflux heating state reaction 4h, while heating while stirring, and then with deionized water filtering to wash the straw, in the use of volume of 10mL, the concentration of 0.3mol / L hydrochloric acid neutralize and the residual alkali on the surface of the straw, stand for 15min, filter and wash three times, The stalks are separated and dried at a temperature of 60 °C.

[0085] S3, the load of silver particles: the straw obtained in S2 took 0.6g into the volume of 5mL, the concentration of ...

Embodiment 3

[0122] S1, take the wheat straw and remove the leaves and roots, and then wash, dry and truncate the straw in turn with clean water, sift it with a 20 mesh sieve to obtain a straw greater than 20 mesh, that is, a length of 1 cm, and then wash the straw of this length with deionized water and dry it.

[0123] S2, the use of lye to treat the straw: take 1g S1 of the straw obtained soaked in a volume of 10mL, the concentration of 1mol / L NaOH solution, through the temperature of 70 ° C water bath reflux heating state reaction 2h, while heating while stirring, and then with deionized water filtering to wash the straw, in the use of volume of 10mL, the concentration of 0.2mol / L hydrochloric acid neutralize and residual alkali on the surface of the straw, stand for 10min, filter and wash three times, The stalks are separated and dried at a temperature of 80 °C.

[0124] S3, the load of silver particles: the straw obtained in S2 took 0.7g into the volume of 10mL, the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com