Organic/inorganic hybrid polymer capable of reducing water vapor transmittance

A technology of water vapor transmission rate and inorganic oxides, which is applied in semiconductor/solid-state device manufacturing, coating, electric solid-state devices, etc., can solve low water vapor transmission rate, weak water vapor barrier performance, inability to fill pinholes and cracks and other problems, to achieve the effect of easy operation of equipment and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

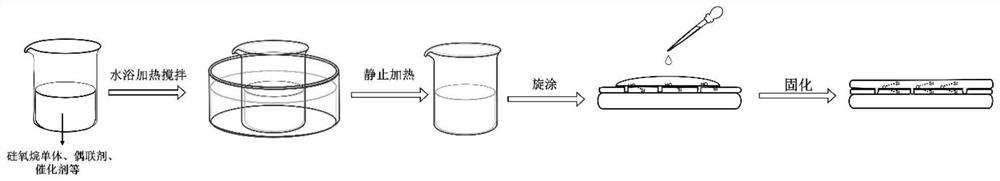

[0027] The synthetic method is as follows:

[0028] Step 1. Mix the organosiloxane resin with the coupling agent KH-560 in a ratio of 95:5 by mass, and heat in a water bath.

[0029] Step 2. Stir for 20 min under heating in a water bath at 100°C, and seal in the meantime.

[0030] Step 3. After the stirring is stopped, let it stand while the heating temperature of the water bath is 100°C and the time is 20min.

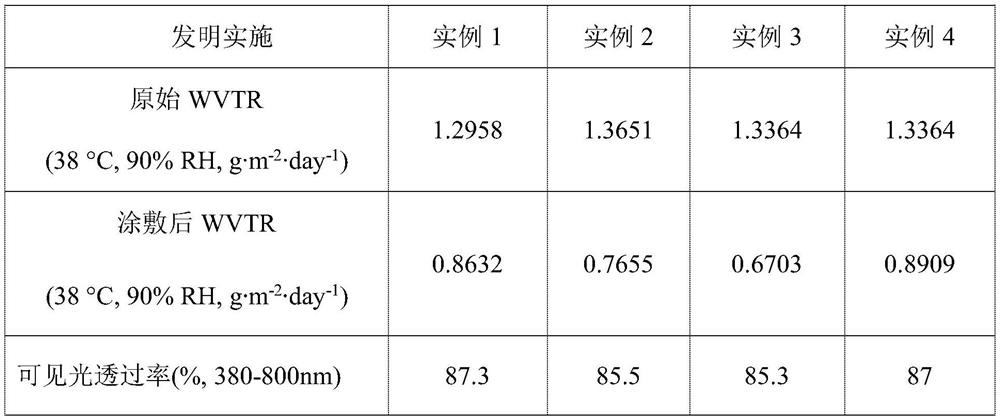

[0031] Step 4. The WVTR with UV light is 1.2958g m -2 ·day -1 The left and right silicon oxide barrier films were treated for 10 min.

[0032] Step 5. Spin coating a layer of 1um organic / inorganic hybrid polymer on the surface of the silicon oxide barrier film by spin coating.

[0033] Step 6. Curing at 60°C for 24 hours.

[0034] The water vapor barrier properties and light transmittance properties of the samples were tested by using the C390H water vapor transmission instrument of Languang Company and the UV-Vis-Near Infrared Spectrophotometer (UV-3600) of Shima...

Embodiment 2

[0036] The synthetic method is as follows:

[0037] Step 1. Mix the organosiloxane resin with the coupling agent KH-560 in a ratio of 90:10 by mass, and heat in a water bath.

[0038] Step 2. Stir for 20 min under heating in a water bath at 100°C, and seal in the meantime.

[0039] Step 3. After the stirring is stopped, let it stand while the heating temperature of the water bath is 100°C and the time is 20min.

[0040] Step 4. The WVTR with UV light is 1.3651g m -2 ·day -1 The left and right silicon oxide barrier films were treated for 10 min.

[0041] Step 5. Spin coating a layer of 1um organic / inorganic hybrid polymer on the surface of the silicon oxide barrier film by spin coating.

[0042] Step 6. Curing at 60°C for 24 hours.

[0043] The water vapor barrier properties and light transmittance properties of the samples were tested by using the C390H water vapor transmission instrument of Languang Company and the UV-Vis-Near Infrared Spectrophotometer (UV-3600) of Shim...

Embodiment 3

[0045] The synthetic method is as follows:

[0046] Step 1. Mix the organosiloxane resin with the coupling agent KH-560 in a ratio of 85:15 by mass, and heat in a water bath.

[0047] Step 2. Stir for 20 min under heating in a water bath at 100°C, and seal in the meantime.

[0048] Step 3. After the stirring is stopped, let it stand while the heating temperature of the water bath is 100°C and the time is 20min.

[0049] Step 4. The WVTR is 1.3364g m with UV light -2 ·day -1 The left and right silicon oxide barrier films were treated for 10 min.

[0050] Step 5. Spin coating a layer of 1um organic / inorganic hybrid polymer on the surface of the silicon oxide barrier film by spin coating.

[0051] Step 6. Curing at 60°C for 24 hours.

[0052] The water vapor barrier properties and light transmittance properties of the samples were tested by using the C390H water vapor transmission instrument of Languang Company and the UV-Vis-Near Infrared Spectrophotometer (UV-3600) of Shim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com