Thick copper etching composition and application thereof

A copper etching and composition technology, which is applied in the field of semiconductor wafer packaging, can solve the problems of generating a large number of bubbles in the reaction, the photoresist is peeled off, and cannot be effectively etched, and achieves high etching rate stability, good etching selection ratio, and optimal etching. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] The following examples and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to the following examples as long as the gist of the present invention is not exceeded.

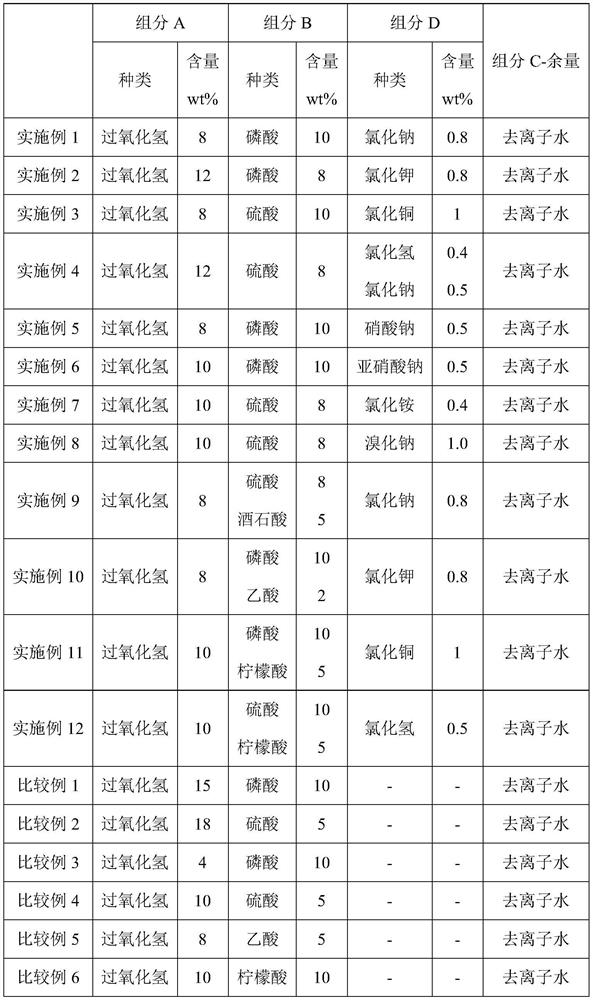

[0097] The following is a description of the components used in the Examples and Comparative Examples, in weight percent (%), as shown in Table 1.

[0098] Table 1. Specific substances and amounts used for the etching compositions provided by the examples and comparative examples

[0099]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com