Copper plating additive, copper plating solution and application thereof

A technology of copper plating solution and additive, applied in copper plating additive, copper plating solution and its application fields, can solve the problems such as the appearance of the coating is not bright enough, the coating is not uniform, and achieve the effects of low cost, fine grains, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

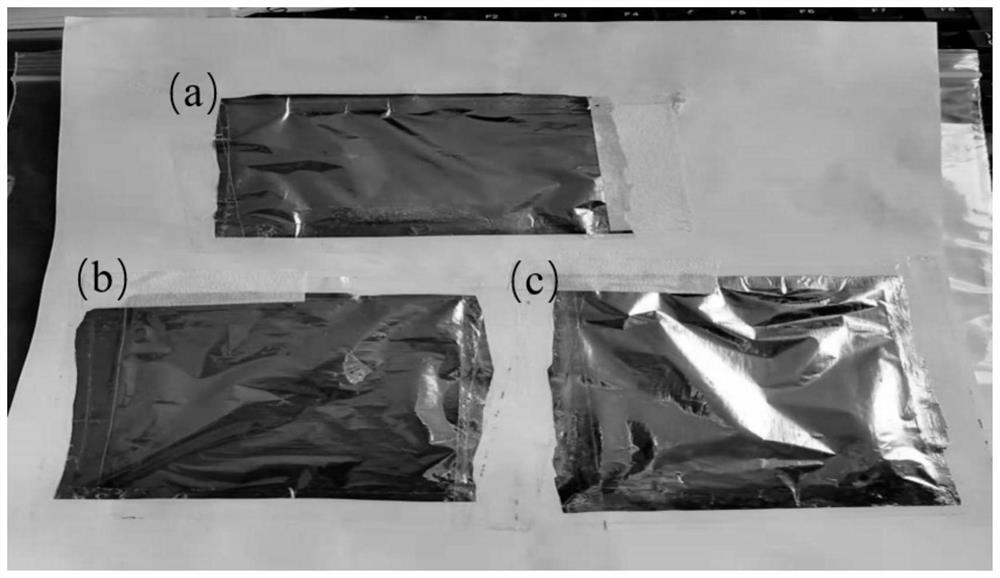

Image

Examples

Embodiment 1

[0063] (1) In the present embodiment, the composition of the copper plating additive per liter is as follows:

[0064] 1,4-cyclohexanedione monoethylene glycol ketal 10g,

[0065] Phthalimide Potassium Salt 20g and

[0066] 3-amino-1,2-propanediol 30g.

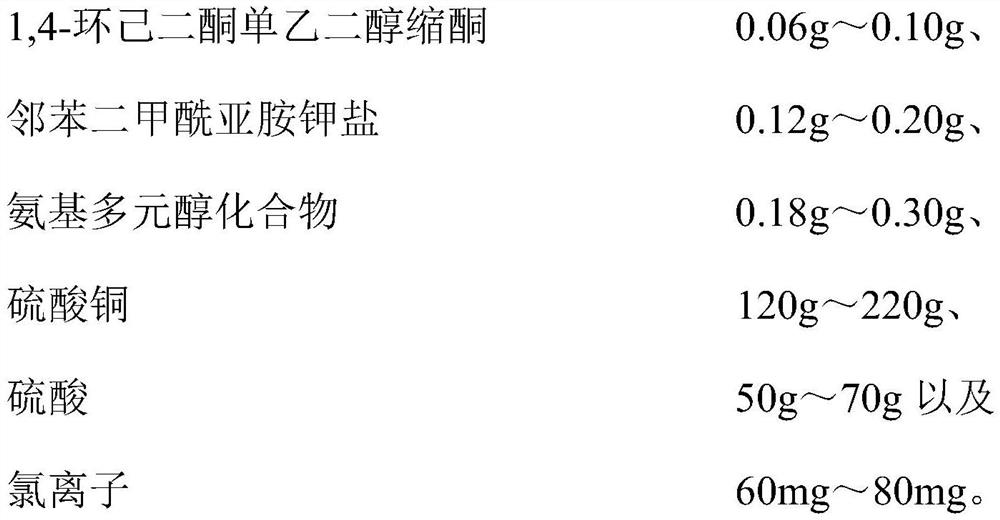

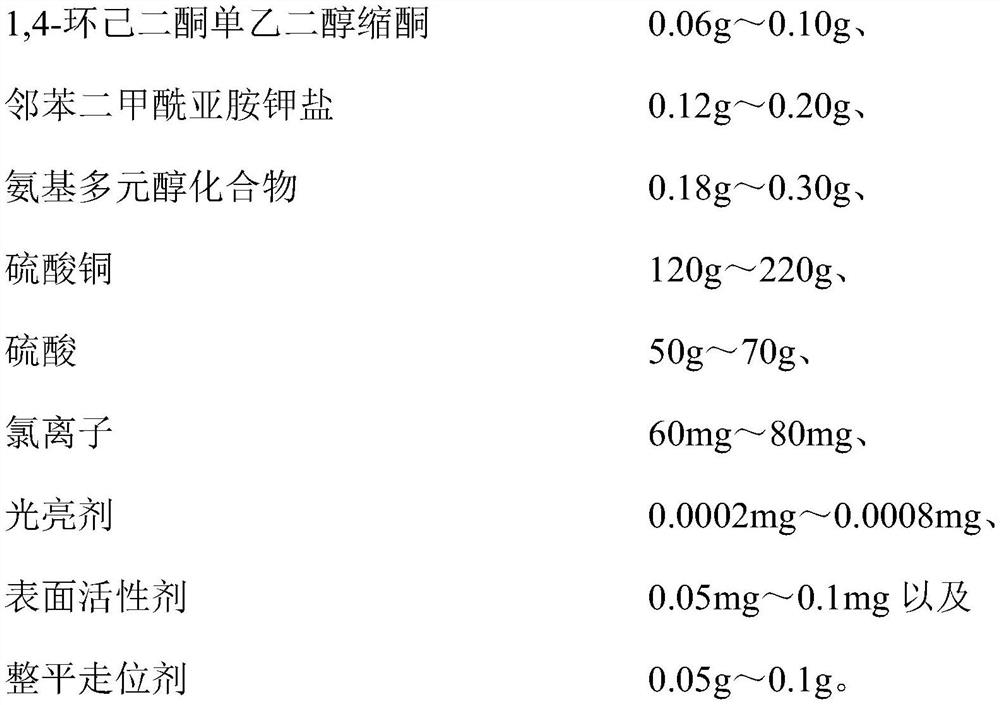

[0067] (2) In the present embodiment, every liter of described copper plating solution is made up of water and following components:

[0068]

[0069]

[0070] (3) the preparation method of the copper plating solution described in the present embodiment is as follows:

[0071] 1) Prepare 1,4-cyclohexanedione monoethylene glycol ketal solution: dissolve 10 g of 1,4-cyclohexanedione monoethylene glycol ketal in 200 ml of deionized water, stir and dissolve until clear, and set aside;

[0072] 2) Preparation of phthalimide potassium salt: use an analytical balance to weigh 20 g for preparation, and set aside;

[0073] 3) Prepare 3-amino-1,2-propanediol solution: dissolve 30g of 3-amino-1,2-propanediol in 500ml of deioniz...

Embodiment 2

[0082](1) In the present embodiment, the composition of the copper plating additive per liter is as follows:

[0083] 1,4-cyclohexanedione monoethylene glycol ketal 6g,

[0084] Phthalimide Potassium Salt 12g and

[0085] 3-Amino-1,2-propanediol 18g.

[0086] (2) In the present embodiment, every liter of described copper plating solution is made up of water and following components:

[0087]

[0088] (3) the preparation method of the copper plating solution described in the present embodiment is as follows:

[0089] 1) Prepare 1,4-cyclohexanedione monoethylene glycol ketal solution: dissolve 6 g of 1,4-cyclohexanedione monoethylene glycol ketal in 200 ml of deionized water, stir and dissolve until clear, and set aside;

[0090] 2) Preparation of phthalimide potassium salt: use an analytical balance to weigh 12 g for preparation, and set aside;

[0091] 3) Prepare 3-amino-1,2-propanediol solution: dissolve 18g of 3-amino-1,2-propanediol in 500ml of deionized water, stir ...

Embodiment 3

[0100] (1) In the present embodiment, the composition of the copper plating additive per liter is as follows:

[0101] 1,4-cyclohexanedione monoethylene glycol ketal 7g,

[0102] Phthalimide Potassium Salt 14g and

[0103] 3-amino-1,2-propanediol 21g.

[0104] (2) In the present embodiment, every liter of described copper plating solution is made up of water and following components:

[0105]

[0106] (3) the preparation method of the copper plating solution described in the present embodiment is as follows:

[0107] 1) Prepare 1,4-cyclohexanedione monoethylene glycol ketal solution: dissolve 7 g of 1,4-cyclohexanedione monoethylene glycol ketal in 200 ml of deionized water, stir and dissolve until clear, and set aside;

[0108] 2) Preparation of phthalimide potassium salt: use an analytical balance to weigh 14 g for preparation, and set aside;

[0109] 3) Prepare 3-amino-1,2-propanediol solution: dissolve 21g of 3-amino-1,2-propanediol in 500ml of deionized water, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com