Method for evaluating regeneration efficiency of asphalt regenerant

A technology of asphalt regenerant and regeneration efficiency, which is used in the application of stable shear force to test the strength of materials, instruments, sustainable waste treatment, etc. It can solve the problem that the action time cannot be accurately determined, and the asphalt regenerant lacks regeneration efficiency and proportion. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

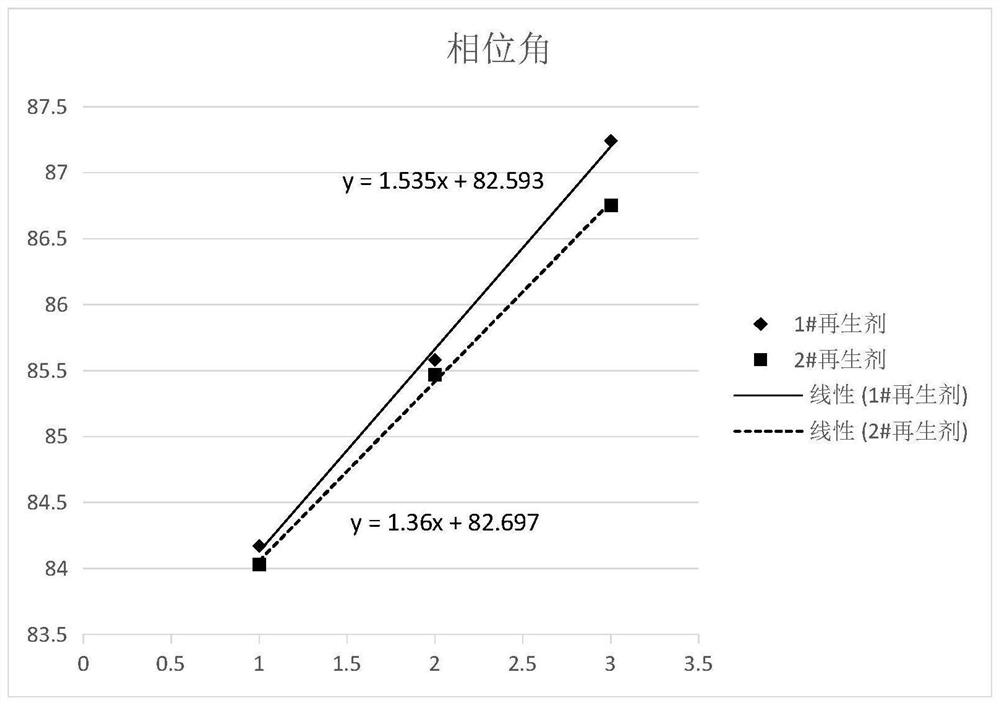

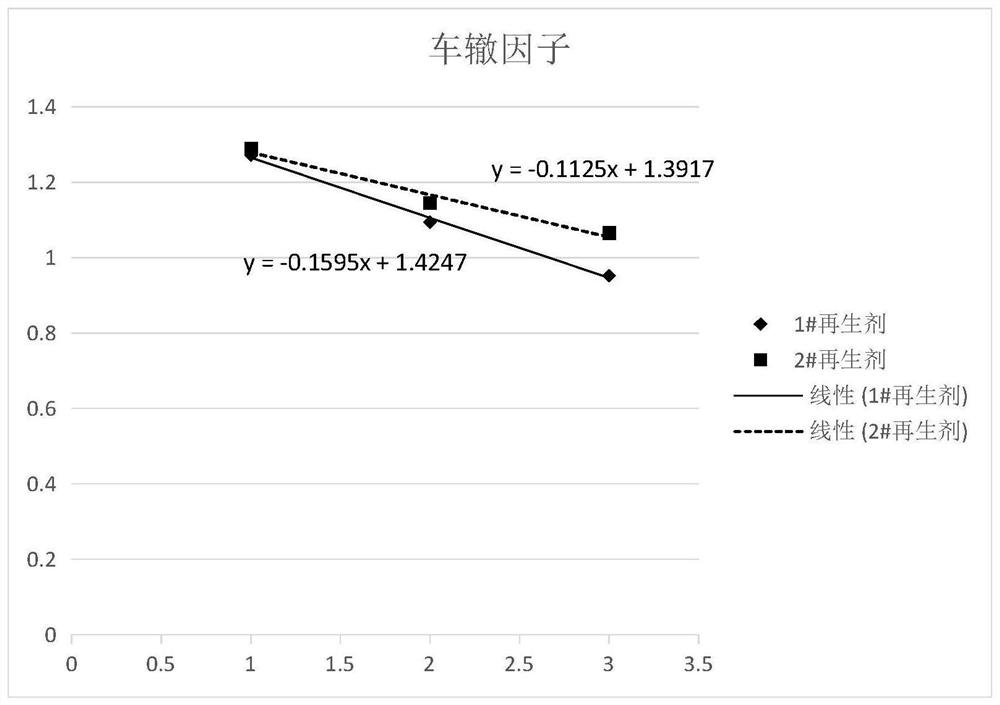

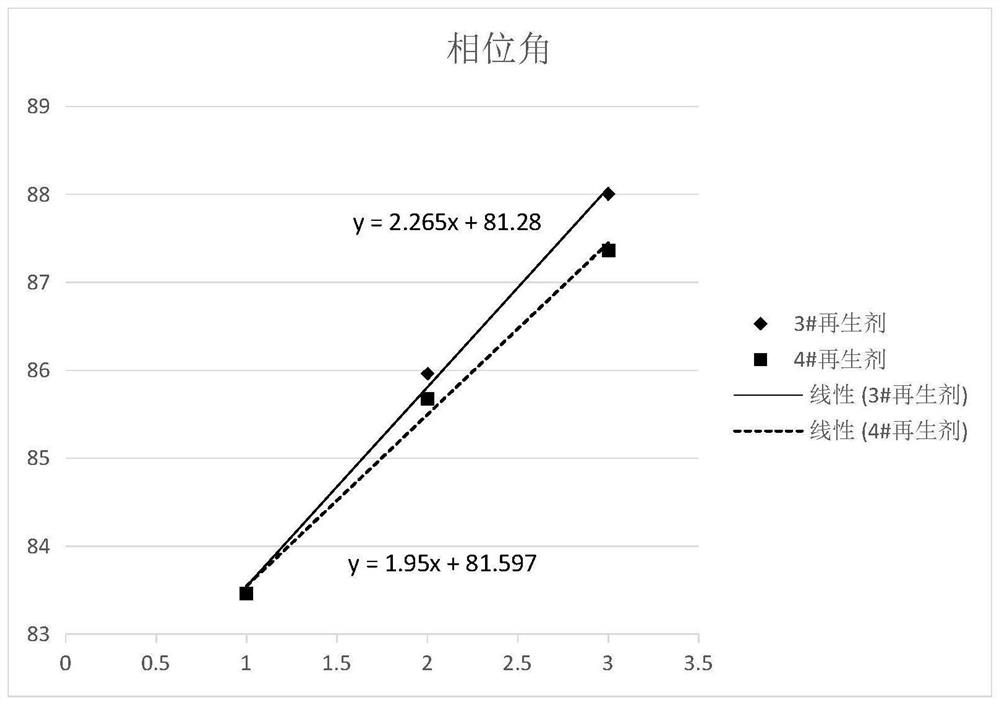

[0033] Embodiment 1, a method for evaluating the regeneration efficiency of an asphalt regenerant, comprising the following steps: Step 1: Select the test temperature according to the usage of the regenerant and the type of asphalt. Generally, the road petroleum asphalt is selected as 100°C or 120°C, and the modified asphalt is selected as 130°C or 150°C. Step 2: Select the action time of the regenerant. In order to ensure that the regeneration effect of the regenerant can be exerted, the selected time period is set as three action times of 0.5h, 1h and 3h, and the phase angle curve of the regenerated asphalt corresponding to these three periods of time is used as the evaluation. Basis for the regeneration rate of the regenerant. Step 3: Use road petroleum asphalt or modified asphalt to conduct PAV test (JTG E20-2011T0630-2011). PAV test is an accelerated aging method of asphalt. Provide an air pressure of 2.1MPa±0.1MPa, put the asphalt sample into the pressure vessel, keep i...

Embodiment 2

[0034] Example 2, the method for evaluating the regeneration efficiency of the asphalt regenerant described in Example 1, in the step 1, the test temperature is selected according to the usage of the regenerant and the type of asphalt, 100 ° C or 120 ° C is selected, and 130 ° C is selected for the modified asphalt or 150°C.

Embodiment 3

[0035] Example 3, the method for evaluating the regeneration efficiency of the asphalt rejuvenating agent described in Example 1 or 2, in the step 3, the road petroleum asphalt or modified asphalt was used for the PAV test, and the temperature inside the pressure vessel was set to 100°C, And provide the air pressure of 2.1MPa, put the asphalt sample into the pressure vessel and keep it for 20h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com