Online intelligent identification method and system for blast furnace tapping end point

A blast furnace tapping and intelligent identification technology, applied in the field of blast furnace smelting, can solve problems such as the inability to accurately identify the end point of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The on-line intelligent identification method for the blast furnace tapping end point provided by the first embodiment of the present invention includes:

[0072] Step S101, collecting the molten iron flow image, and extracting the characteristics of the molten iron flow image according to the molten iron flow image;

[0073] Step S102, collecting molten iron flow data, and extracting short-term time series features of molten iron flow according to the molten iron flow data;

[0074] Step S103, fuse the molten iron flow image features and the molten iron flow short-term time series features to establish a classification prediction model for the tapping process;

[0075] Step S104, according to the classification prediction model of the tapping process, obtain the tapping stage at the current moment;

[0076] Step S105, according to the current tapping stage, identify the blast furnace tapping end point.

[0077] The on-line intelligent identification method for the bl...

Embodiment 2

[0079] The invention classifies the tapping stage of the blast furnace by extracting data time series features such as molten iron flow velocity, temperature, slag-to-iron ratio, etc., as well as the image features of the molten iron flow, and fuses them, determines the blast furnace tapping stage at the current moment through the classification results, and finally relies on The stage classification results are used to calculate the blast furnace tapping end point and its confidence.

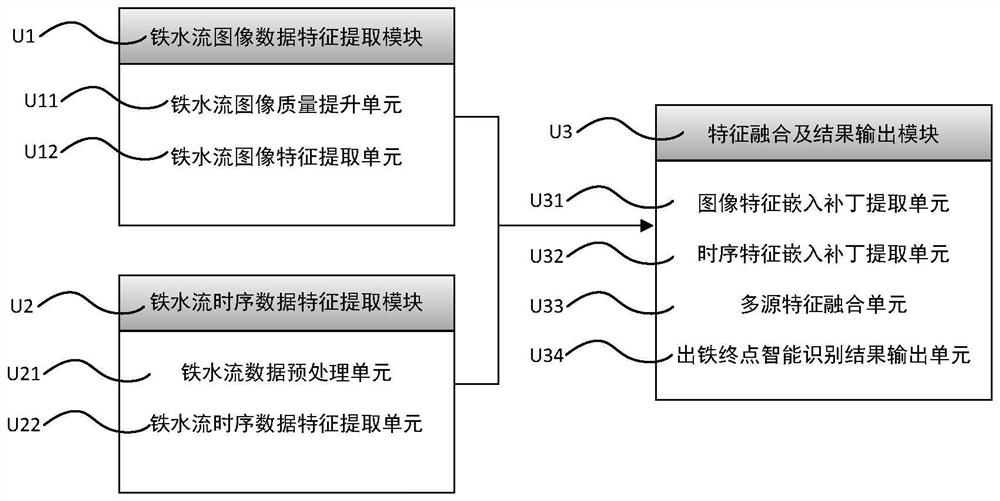

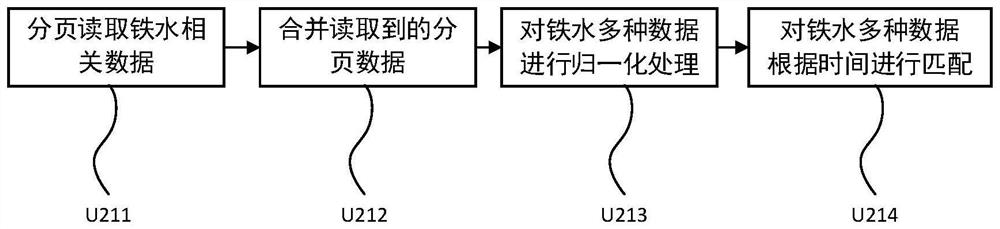

[0080] like figure 1 As shown, the method of the embodiment of the present invention is composed of a molten iron flow image data feature extraction module U1, a molten iron flow time series data feature extraction module U2, and a feature fusion and result output module U3, which are described in detail below:

[0081] Hot metal flow image data feature extraction module U1:

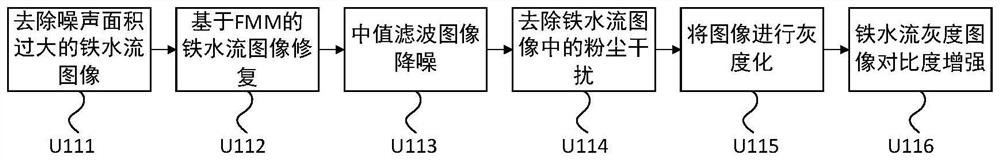

[0082] The main function of this module is to extract features from molten iron flow image data through convolutional ...

Embodiment 3

[0151] The specific embodiments of the present invention are further described in conjunction with the accompanying drawings. The present invention is applied to a domestic 2650m 3 on the blast furnace. Use the python-based pytorch deep learning framework to build an intelligent identification model for the end point of iron casting, collect 6 months of molten iron flow image, temperature, silicon content, flow rate and slag-iron ratio data to train the built model. After the training is completed, the blast furnace can be identified. The status of the tapping end point and its confidence. The specific implementation steps for completing the online intelligent identification of the tapping end point are as follows:

[0152] (1) Collect the data of the on-site molten iron flow image, preprocess the image, first filter the original image, use the fast marching algorithm to repair and perform median filtering and dehazing processing on the image, and then limit the use after gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com