Circuit board manufacturing method for improving signal transmission precision

A manufacturing method and signal transmission technology, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of high cost, complex manufacturing process, low speed and precision, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

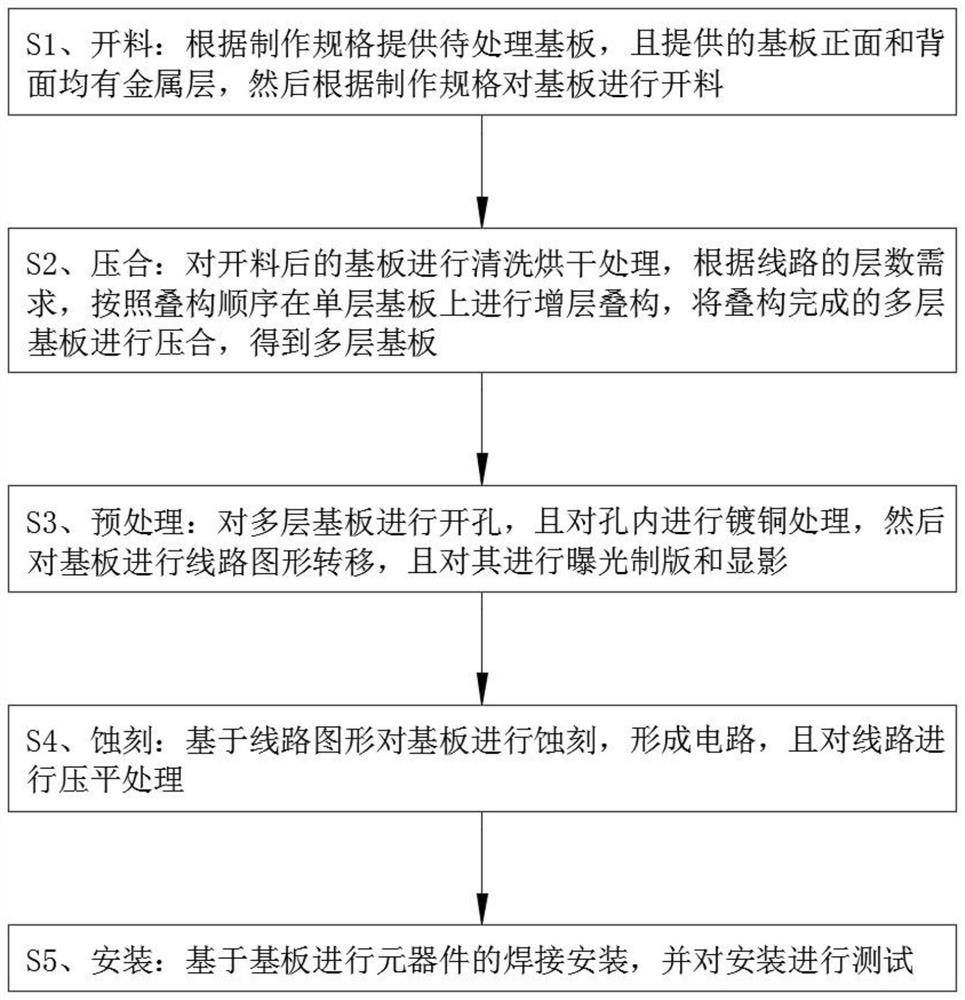

[0029] refer to figure 1 As shown, a method for manufacturing a multilayer circuit board for improving signal transmission accuracy, the method for manufacturing a multilayer circuit board includes the following steps:

[0030] S1. Slicing: Provide the substrate to be processed according to the production specifications, and the provided substrate has a metal layer on the front and back, and then open the substrate according to the production specifications;

[0031] S2. Lamination: Clean and dry the substrate after cutting. According to the number of layers of the circuit, stack the single-layer substrate according to the stacking sequence, and press the laminated multi-layer substrate. to obtain a multi-layer substrate;

[0032] S3. Pretreatment: the multi-layer substrate is opened, and the inside of the hole is copper-plated, and then the circuit pattern is transferred to the substrate, and it is exposed to plate making and development;

[0033] S4. Etching: Etch the subs...

Embodiment 2

[0036] A method for manufacturing a multilayer circuit board for improving signal transmission accuracy, the method for manufacturing the multilayer circuit board comprises the following steps:

[0037] S1. Slicing: Provide the substrate to be processed according to the production specifications, and the provided substrate has a metal layer on the front and back. The metal layer is a copper layer with a thickness of 30-50 microns, and a conductive film is arranged between the metal layer and the substrate. , and then cut the substrate according to the production specifications;

[0038] S2. Lamination: Clean and dry the substrate after cutting. According to the requirements of the number of layers of the circuit, stacking is performed on the single-layer substrate according to the stacking sequence, and PP is arranged between the stacked single-layer substrates. Sheet, the substrate and the PP sheet are stacked in order to form a pre-fixed circuit, the laminated multilayer sub...

Embodiment 3

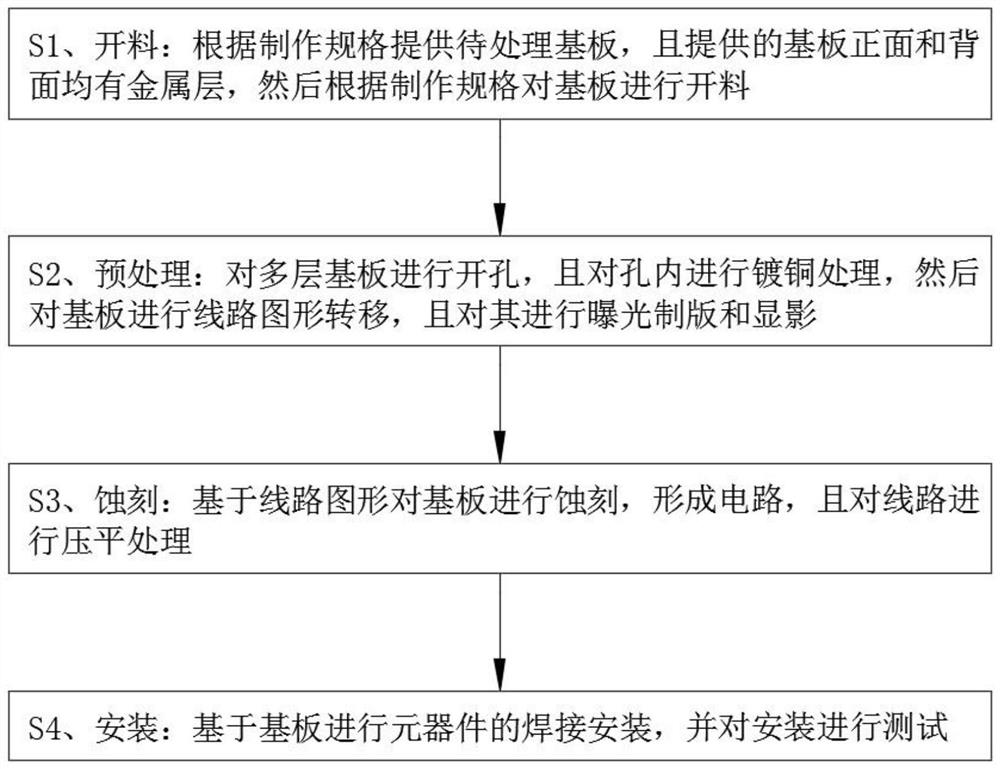

[0043] refer to figure 2 As shown, a method for manufacturing a single-layer circuit board for improving signal transmission accuracy, the method for manufacturing a single-layer circuit board includes the following steps:

[0044] S1. Slicing: Provide the substrate to be processed according to the production specifications, and the provided substrate has a metal layer on the front and back, and then open the substrate according to the production specifications;

[0045] S2, pretreatment: the multi-layer substrate is opened, and the inside of the hole is copper-plated, and then the circuit pattern is transferred to the substrate, and it is exposed to plate making and development;

[0046] S3. Etching: The substrate is etched based on the circuit pattern to form a circuit, and the circuit is flattened;

[0047] S4. Installation: Based on the substrate, the components are welded and installed, and the installation is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com