Method for preparing graft copolymer and graft copolymer prepared thereby

A technology for graft copolymers and polymers, applied in the field of graft copolymers, can solve the problems of deterioration of processing performance and surface characteristics, and reduced impact resistance, and achieves a reduced molecular weight distribution, excellent impact resistance, and excellent processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

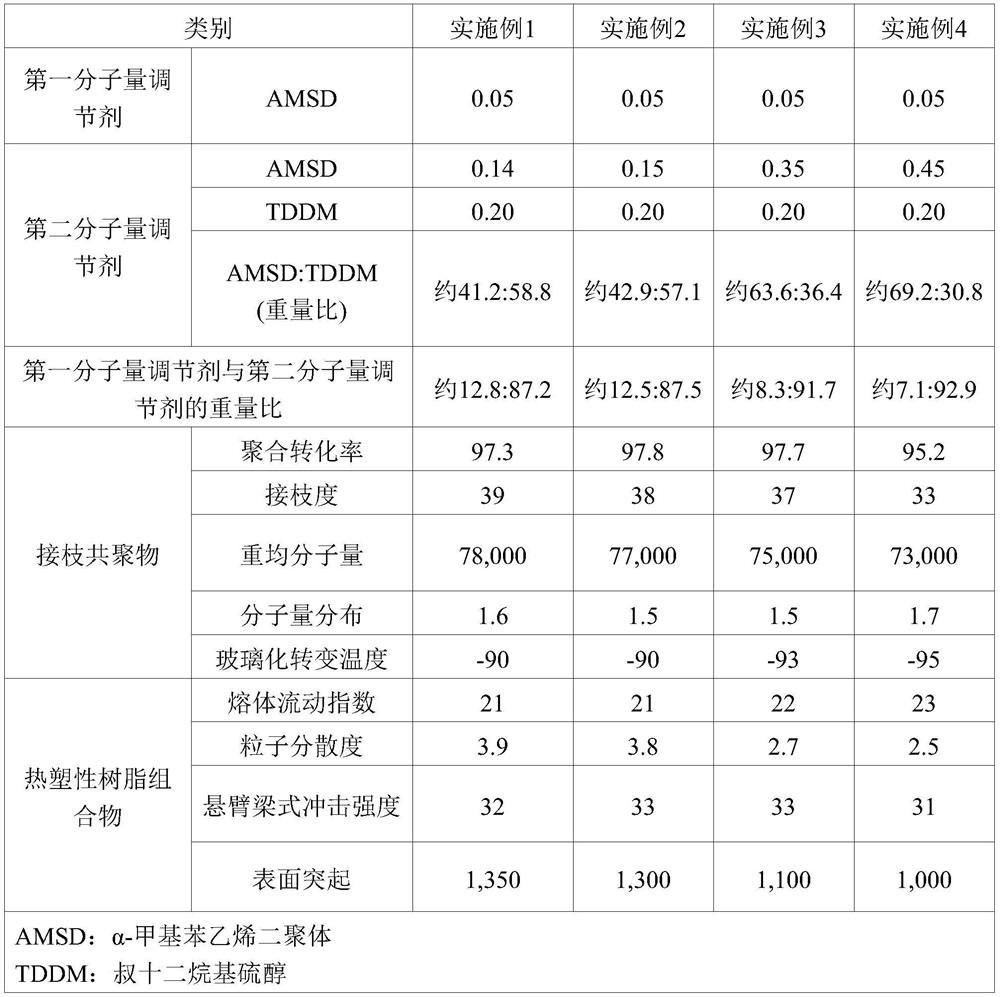

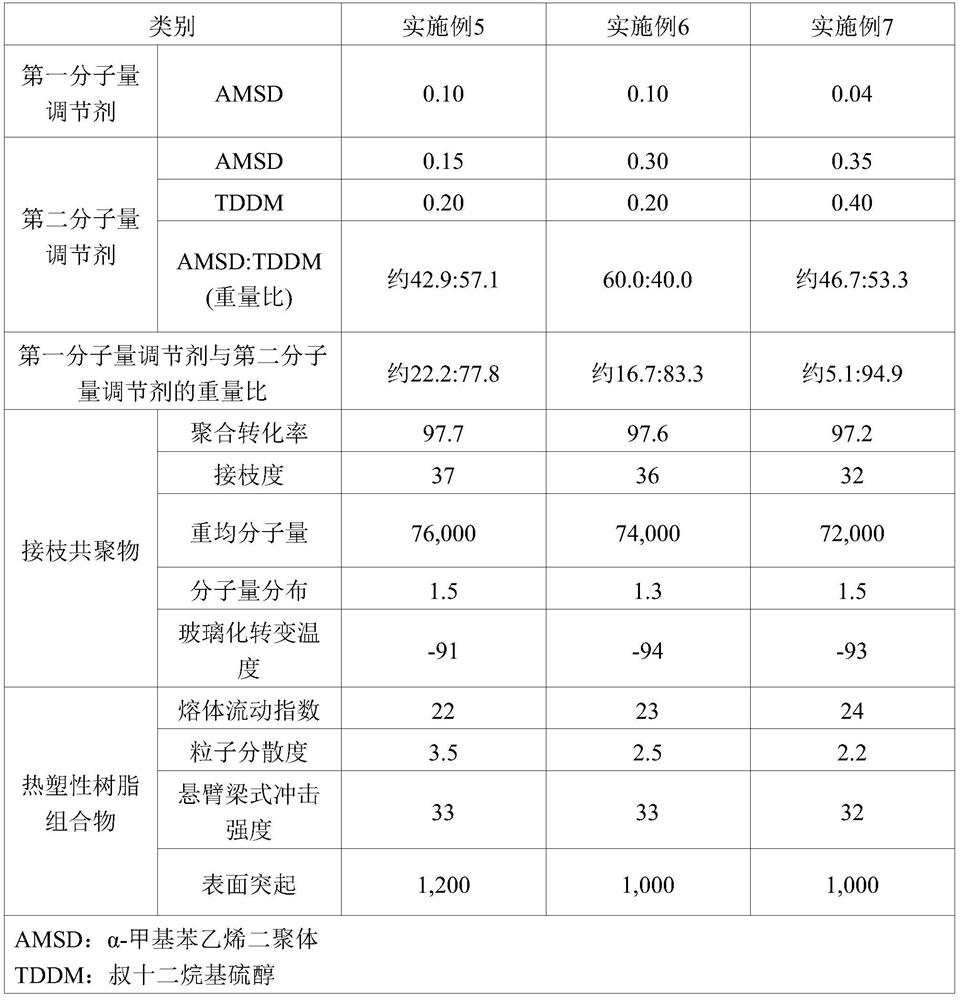

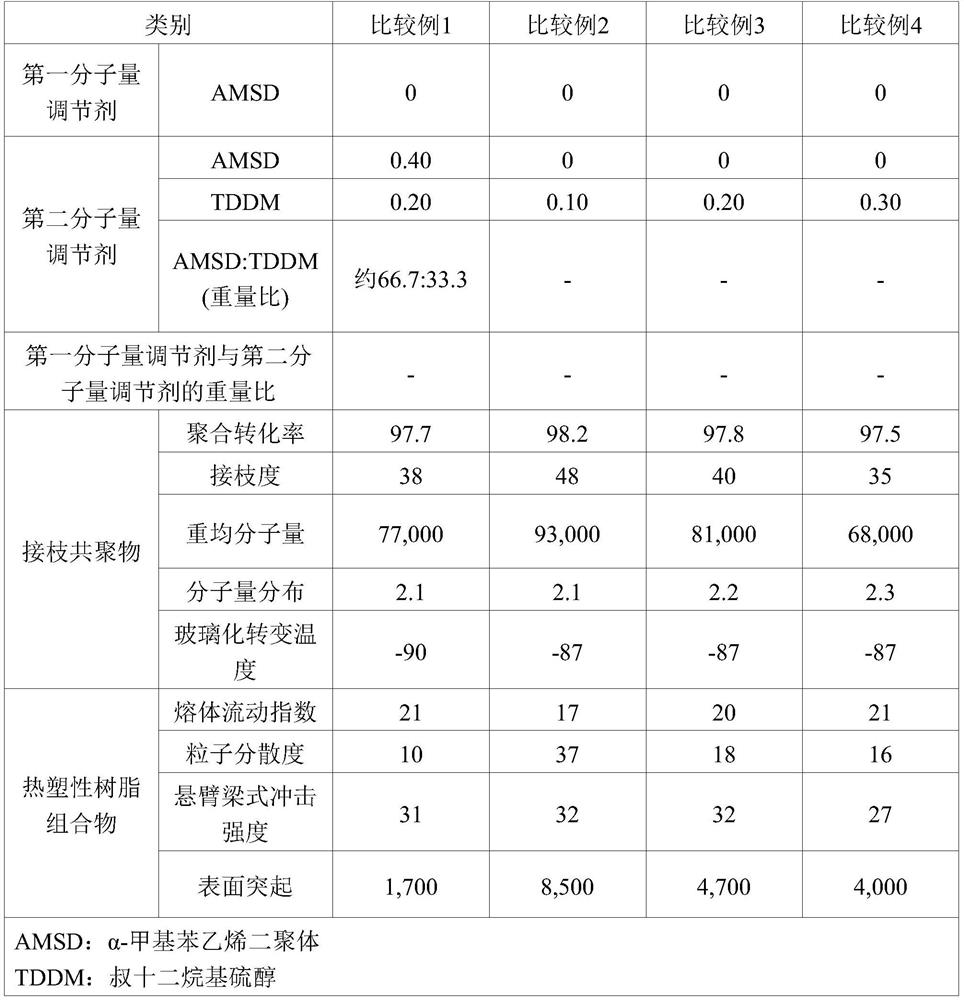

[0041] A method for preparing a graft copolymer according to an embodiment of the present invention includes: adding a first molecular weight modifier, a diene-based rubber polymer, an aromatic vinyl-based monomer and a vinyl cyanide-based monomer to a reaction in batches and a second molecular weight regulator, an aromatic vinyl-based monomer, and a vinyl cyanide-based monomer are continuously added to the reactor for polymerization, wherein the second molecular weight regulator comprises weight The alkyl styrene-based dimer and the thiol-based compound in a ratio of 40.0:60.0 to 70.0:30.0, the weight ratio of the first molecular weight modifier to the second molecular weight modifier is 5.0:95.0 to 25.0:75.0 .

[0042] The inventors of the present invention have found that when the continuous addition is performed by adjusting the alkylstyrene-based dimer and the thiol-based compound so that they are contained in the second molecular weight regulator at a specific weight rat...

Embodiment 1

[0089]

[0090] A first mixed solution was prepared, containing 100.0 parts by weight of ion-exchanged water, 58.0 parts by weight (based on solid content) of butadiene rubber polymer latex (average particle size: 300 nm), 7.5 parts by weight of styrene, 2.5 parts by weight of Acrylonitrile, 0.10 part by weight of potassium oleate, 0.050 part by weight of tetrabutyl hydroperoxide, 0.080 part by weight of glucose, 0.050 part by weight of tetrasodium pyrophosphate, 0.001 part by weight of ferrous sulfate (II) and the following table A first molecular weight regulator in the amount shown in 1.

[0091] In addition, a second mixed solution was prepared containing 12.0 parts by weight of ion-exchanged water, 24.0 parts by weight of styrene, 8.0 parts by weight of acrylonitrile, 0.20 parts by weight of potassium oleate, 0.10 parts by weight of tetrabutyl hydroperoxide, and A second molecular weight regulator in the amounts shown in Table 1 below.

[0092] In addition, a third mix...

Embodiment 2 to Embodiment 7 and comparative example 1 to comparative example 10

[0097] A graft polymer powder and a thermoplastic resin composition were prepared in the same manner as in Example 1, except that the first molecular weight regulator and the second molecular weight regulator were added in the amounts shown in Tables 1 to 5 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com