Manufacturing process of C-shaped sealing ring

A manufacturing process and sealing ring technology, which is applied in the manufacturing process of C-shaped sealing rings, can solve problems such as sealing failure and leakage between the valve body and valve seat, and achieve the effects of improving production and manufacturing efficiency, reducing manufacturing difficulty, and realizing automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

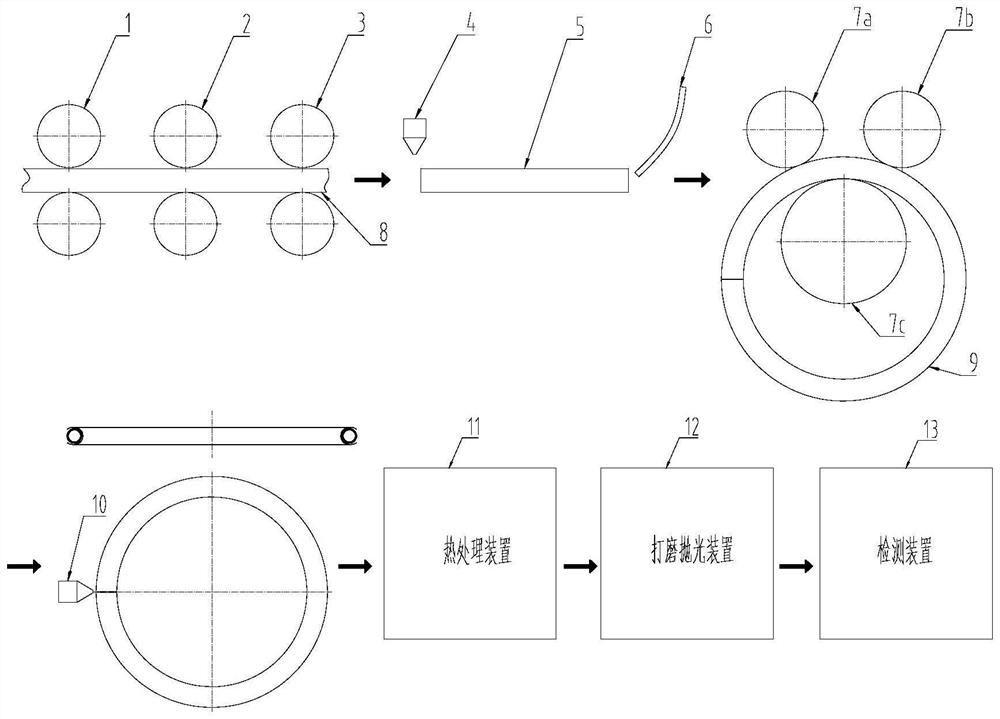

[0030] refer to Figure 1-3 As shown, the present invention provides a manufacturing process of a C-shaped sealing ring, comprising the steps of:

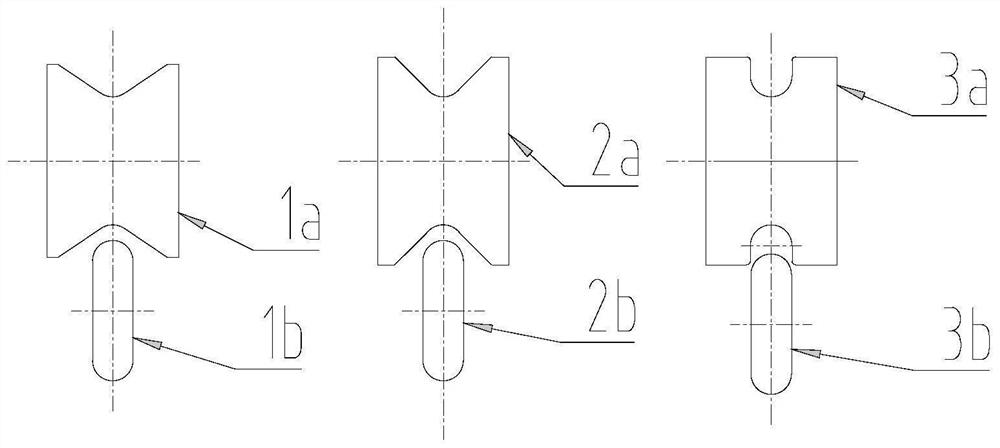

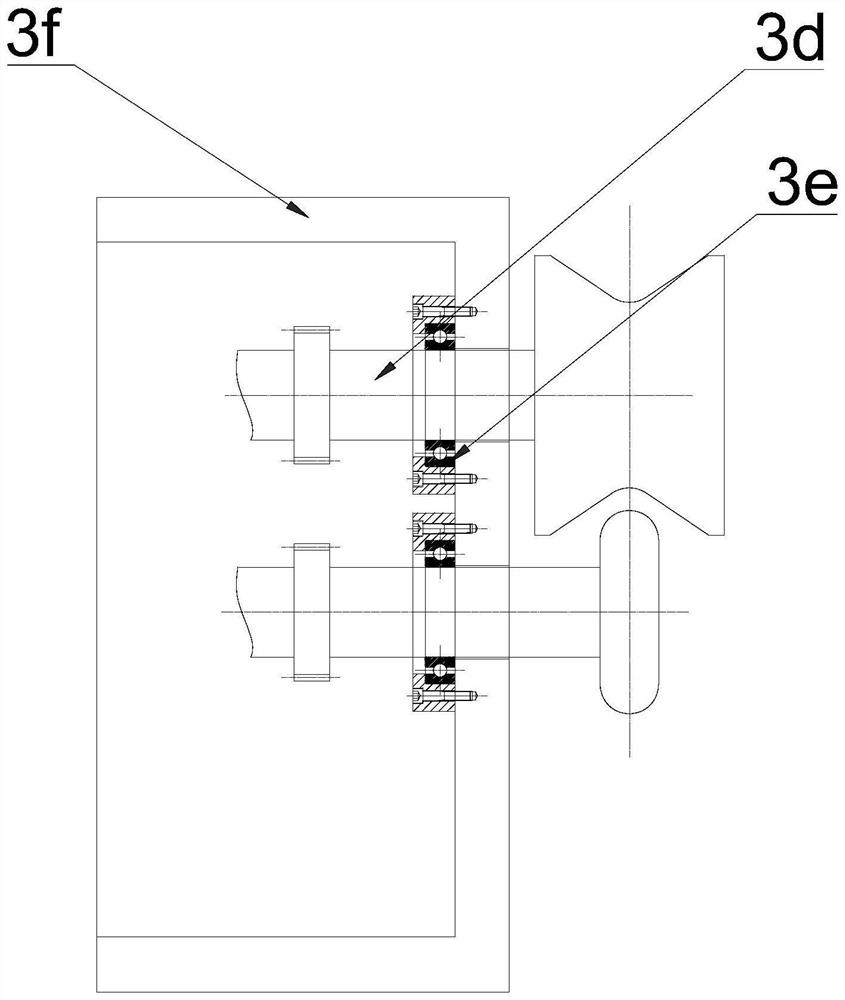

[0031] Step S1: Make the blank plate 8 into a C-shaped truncated long strip profile through the forming and pressing device. The forming and pressing device includes at least a pair of forming rollers, and the forming rollers include concave wheels and cams. The rotation drives the blank plate 8 to advance;

[0032] Step S2: Cutting the C-shaped truncated surface long strip profile into a C-shaped truncated fabric material 5 with a preset length and size by laser cutting equipment 4;

[0033] Step S3: roll the circle by the automatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com