Electroplating clamp and assembly line capable of realizing vertical rack plating and horizontal rotary electroplating

An electroplating fixture and assembly line technology, applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve the problems of electroplating solution leakage, pollution of cathode contact substrate area, poor sealing of electroplating fixture, etc., to maintain stability, improve electroplating effect, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

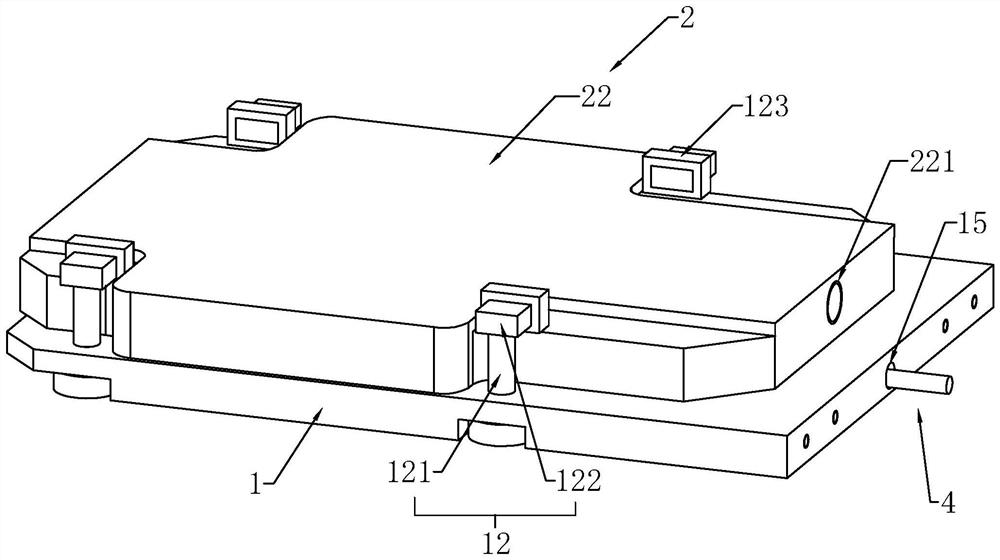

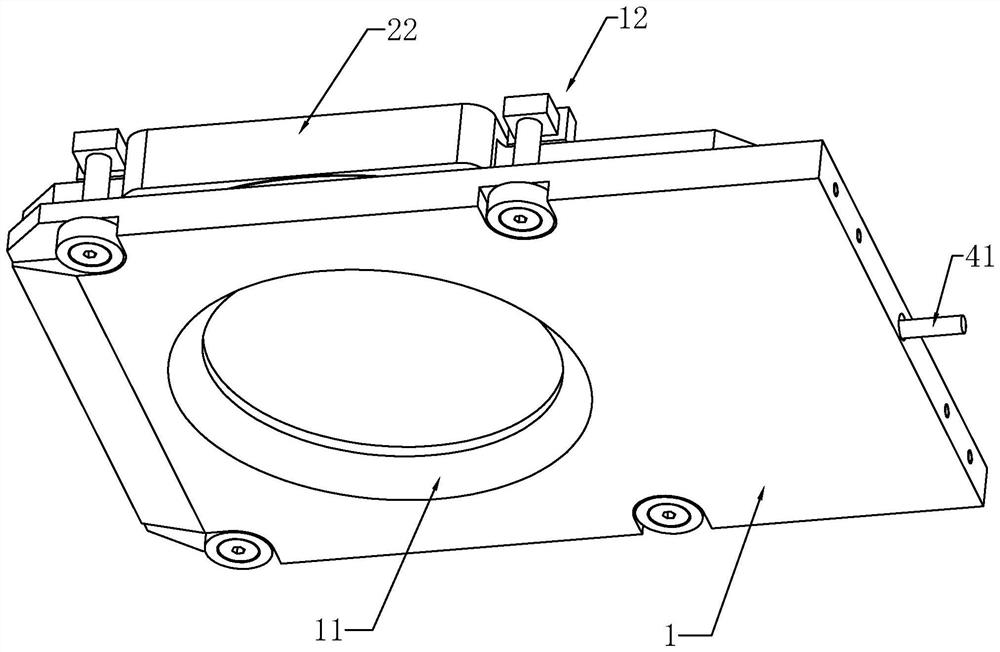

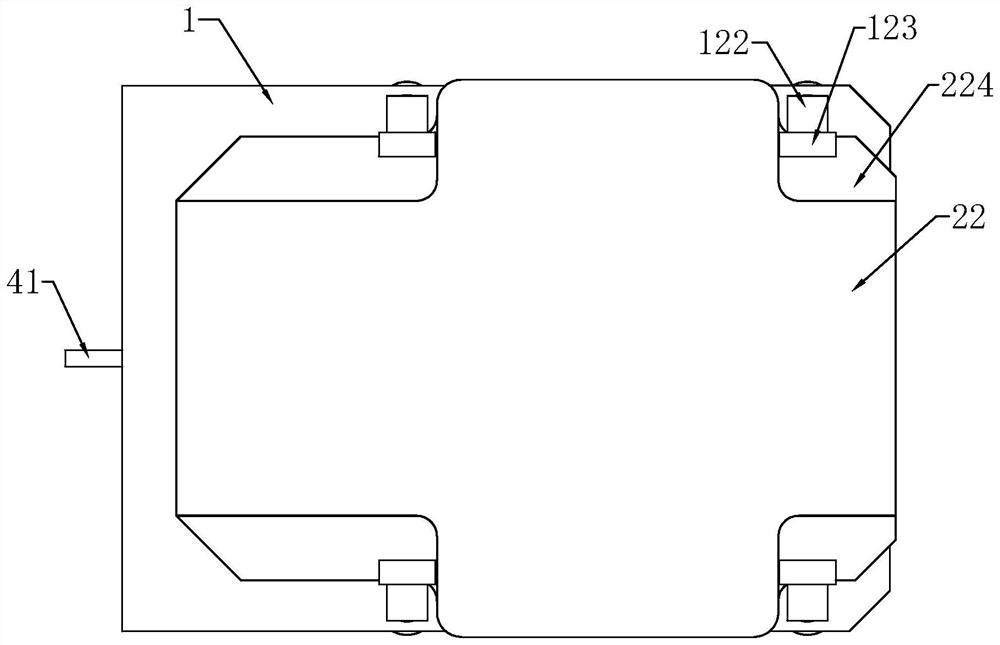

[0051] refer to figure 1 , an electroplating fixture, including a support plate 1 and a seal 2 .

[0052] refer to figure 1 and figure 2 , the support plate 1 is provided with a cavity 11 along its thickness direction. The cavity 11 has a flared structure. When installing the base plate 3, the base plate 3 is placed on the support plate 1, and the side with the smaller diameter of the cavity 11 is shielded. The support plate 1 is also mounted with a conductive component 4 for contacting and conducting electricity with the substrate 3 .

[0053] refer to image 3 and Figure 4 , the sealing member 2 includes a sealing plate 21 and a driving member. The sealing plate 21 has a disc structure as a whole. The sealing plate 21 is used to shield the side of the substrate 3 away from the support plate 1 . Since the substrate 3 is usually thin, a buffer pad 211 is embedded and fixed on the side of the sealing plate 21 close to the support plate 1 , and the buffer pad 211 can ...

Embodiment 2

[0070] refer to Figure 13 and Figure 14 , and the difference from the first embodiment is that the first annular groove 13 is opened on a side wall of the sealing plate 21 close to the supporting plate 1 . The first sealing ring 5 is embedded and fixed in the first annular groove 13 . The height of the outer peripheral groove wall of the first annular groove 13 is higher than that of the inner peripheral groove wall.

Embodiment 3

[0072] refer to Figure 15 The difference from the first embodiment is that the conductive ring 42 is an integral annular structure, the conductive ring 42 and the elastic contact piece 43 are integrally connected, and the conductive ring 42 and the conductive rod 41 can be fixed by welding. One end of the elastic contact piece 43 is connected to the inner wall of the conductive ring 42 , the other end is arched toward the sealing plate 21 and then extends away from the sealing plate 21 , and the end extends axially along the conductive ring 42 as a whole. The elastic contact piece 43 has a curved strip-like structure as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com