Moisture-resistant vitamin mineral tablet and moisture-resistant treatment method thereof

A technology of vitamins and minerals, applied in chemical instruments and methods, chemical/physical processes, drug combinations, etc., can solve the problems of unavoidable moisture absorption of materials, improve moisture resistance, improve moisture resistance, and improve granulation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0066] Preparation Example 1 provides a method for choline particles:

[0067] Step 1: prepare a hydroxypropyl methylcellulose solution, weigh 20 kg of hydroxypropyl methylcellulose, add it to 313 kg of water, and stir at a stirring speed of 200 r / min for 1 h to obtain a hydroxypropyl methylcellulose solution.

[0068] Step 2: Weigh 50kg of choline bitartrate that has passed through a 40-mesh sieve after crushing, place it in a high-speed shearing wet granulator, then 15kg of low-substituted hydroxypropyl cellulose, mix for 10min under the condition of a stirring speed of 120r / min , and then add the hydroxypropyl methylcellulose solution in step S1, and stir for 5 minutes at a stirring speed of 120 r / min and a cutter speed of 1500 r / min to prepare wet granules.

[0069] Step 3: The wet granules are placed in the fluidized bed for drying. Drying conditions: the fluidized bed inlet air setting temperature is 80°C. When the moisture content of the granules reaches (2±0.5)%, the d...

preparation example 2

[0071] Preparation Example 2 provides a continuous granulator for preparing choline granules, and a method for preparing choline granules.

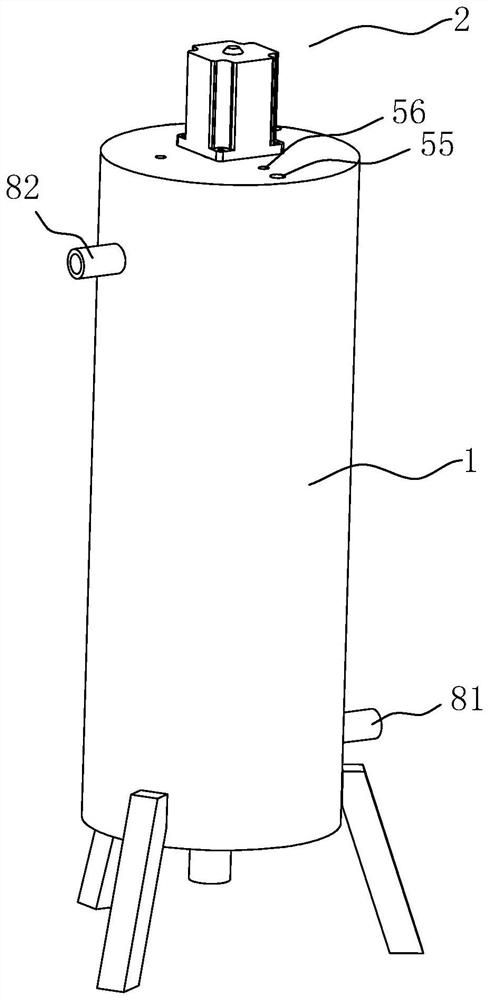

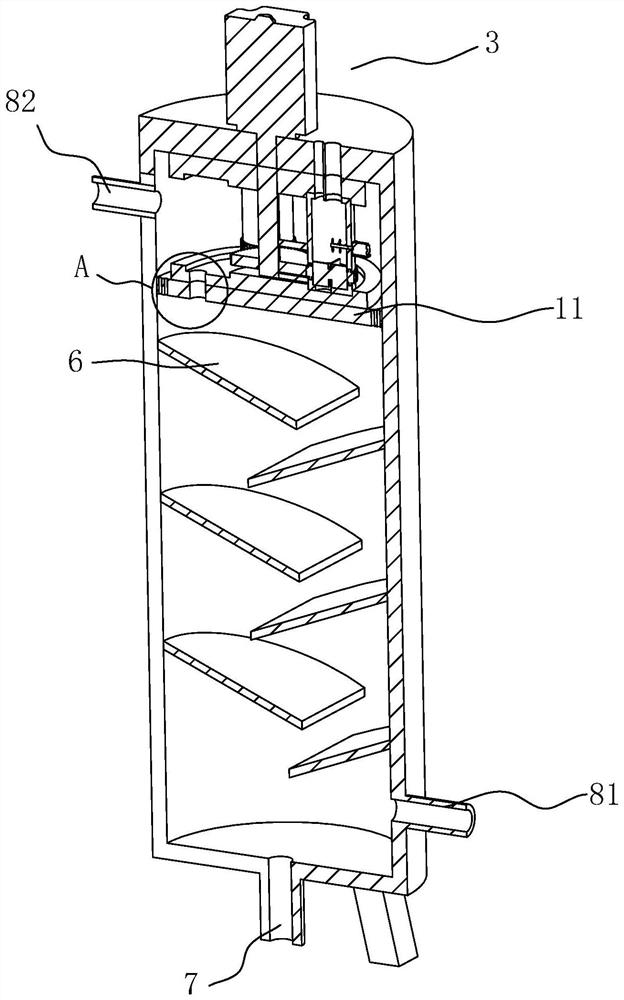

[0072] refer to figure 1 and figure 2 , the continuous granulator includes a cylindrical tower body 1, a columnar cavity is opened inside the tower body 1, and a circular block for dividing the tower body 1 into an upper cavity and a lower cavity is horizontally and fixedly connected in the tower body 1 Separator 11.

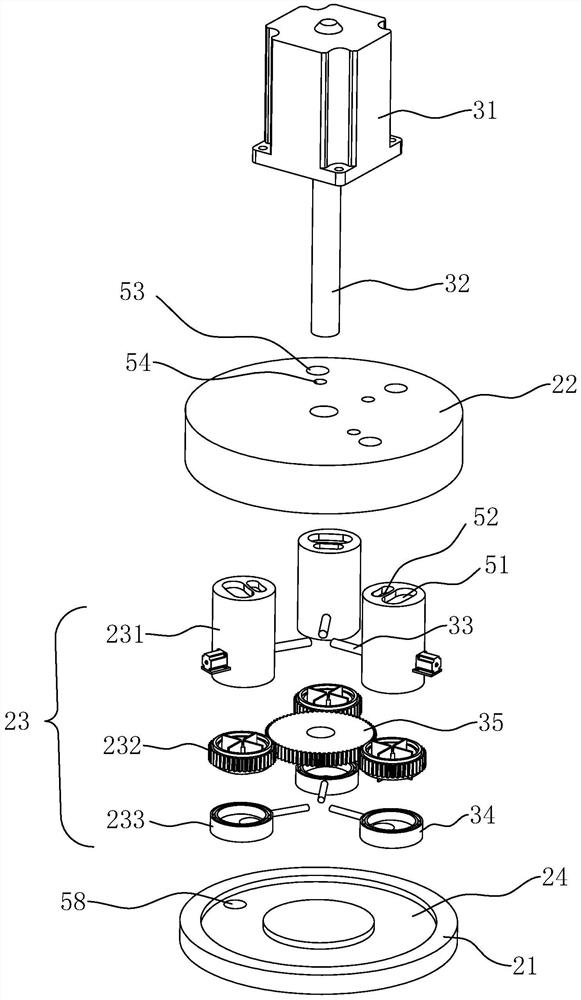

[0073] refer to figure 2 and image 3 , a mixing device 2 is installed above the partition plate 11 , and the mixing device 2 includes a circular bottom plate 21 fixedly connected to the top wall of the partition plate 11 , a top plate 22 and a material tank 23 fixedly connected to the top wall of the upper cavity. A circle of first chute 24 is provided on the side wall of the bottom plate 21 away from the partition plate 11 along the circumference of the bottom plate 21 , and a circle of the top plate 22 close to the...

preparation example 3

[0088] The difference between Preparation Example 3 and Preparation Example 2 is that step S2 is: weigh 50kg of choline bitartrate, 15kg of low-substituted hydroxypropyl cellulose, hydroxypropyl methylcellulose solution and 3kg of 40 mesh sieves after pulverizing. The auxiliary agents are respectively connected to the feeding hole 53 of the tower body 1 through pipes along the sliding direction of the feeding tank 23, and the material is put into the feeding tank 23 through the feeding hole 53, and the stirring speed in the feeding tank 23 is controlled to 120r / min. The rotating speed is 1500r / min, and the air inlet temperature is 80°C; the material obtained from the continuous granulator is taken out and granulated through an 18-mesh screen to obtain choline granules.

[0089] The preparation method of the auxiliary agent is: adding 3kg of sucrose to 10kg of water to melt, then heating and boiling to dryness, and continuing to heat up and cook to dryness to obtain a syrup mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com