Device and method for continuous casting extrusion forming of copper and copper alloy

A copper alloy and casting extrusion technology, which is applied in the field of continuous casting and extrusion forming, can solve the problems of long process and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A device for continuous casting and extruding of copper and copper alloys, comprising a vacuum induction melting furnace, a flow channel and a continuous casting and extruding machine connected in sequence;

[0074] The top of the vacuum induction melting furnace is provided with an inert gas inlet;

[0075] An inert gas inlet is provided on the side wall of the flow channel;

[0076] The continuous casting extruder is provided with an airtight cover of the extrusion wheel;

[0077] The airtight cover of the extrusion wheel is connected with the shoe seat and the deformed body in the continuous casting and extruding machine to realize the sealing of the casting and extrusion space;

[0078] An inert gas inlet is provided on the side wall of the airtight cover of the extrusion wheel.

Embodiment 2

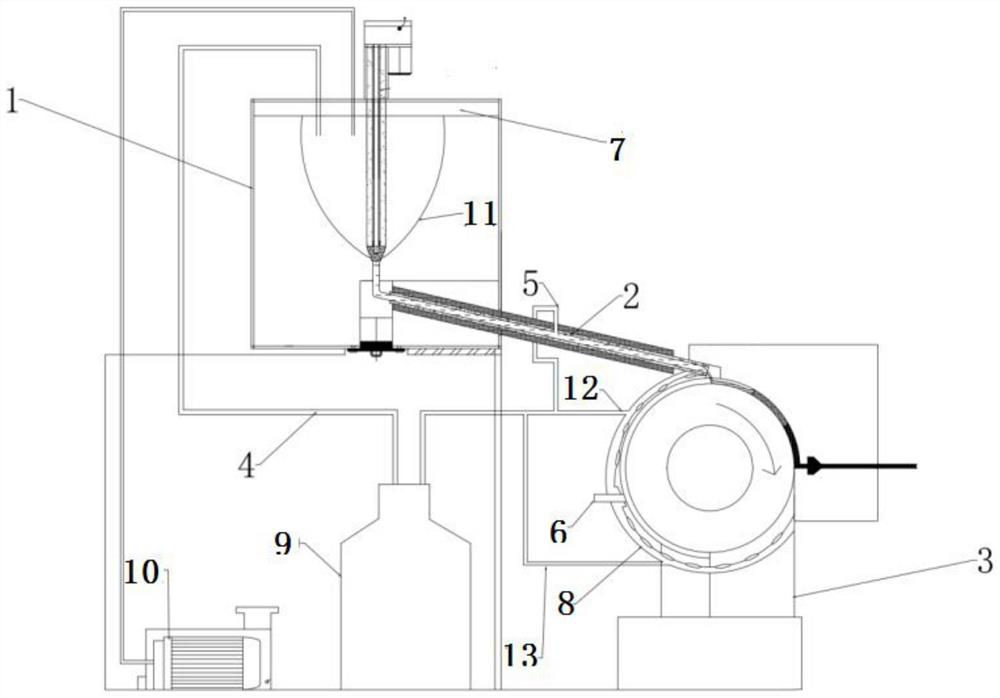

[0080] The schematic structural diagram of the device provided in Example 1 is shown in 1. In the figure, 1 is a vacuum induction melting furnace, 2 is a flow channel, 3 is a continuous casting extruder, 4 is an inert gas pipeline, 5 is an inert gas pipeline, and 6 is an inert gas pipeline. It is a scraper, 7 is a sealing cover, 8 is an airtight cover of the extrusion wheel, 9 is an inert gas storage device, 10 is a vacuum pump, 11 is a crucible, 12 is an inert gas pipeline on the extrusion wheel, and 13 is an inert gas under the extrusion wheel. pipeline;

[0081] The device for continuous casting and extrusion of copper and copper alloys includes a vacuum induction melting furnace 1, a flow channel 2 and a continuous casting and extrusion machine 3 that are connected in sequence;

[0082] The top of the vacuum induction melting furnace 1 is provided with an inert gas inlet;

[0083] The vacuum induction melting furnace 1 is provided with a crucible 11; the top of the crucib...

Embodiment 3

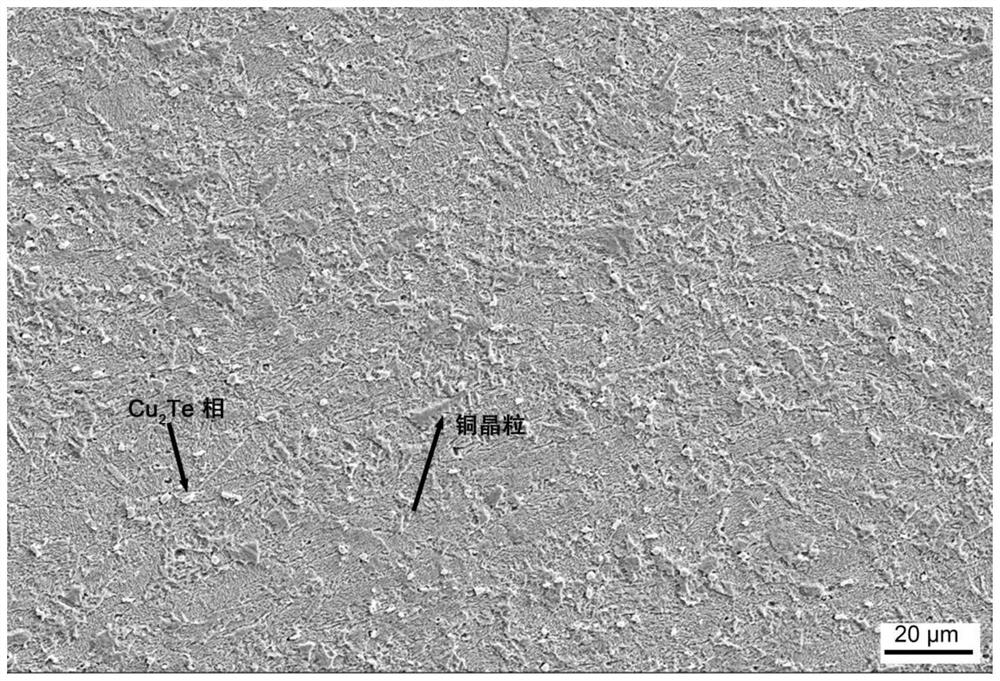

[0098] A method for continuous casting and extrusion of a tellurium-copper alloy, using the device of Example 2 for continuous casting and extrusion of a tellurium-copper alloy, the method is as follows:

[0099] (1) The raw material is added into the vacuum induction melting furnace, and the crucible is evacuated, and the degree of vacuum is 10 -3 Pa, then pass argon gas into the vacuum induction melting furnace through the inert gas inlet, keep the air pressure at 0.1MPa, and then smelt the raw materials in the vacuum induction melting furnace to obtain the first alloy melt; wherein, the tellurium copper alloy The composition is: in terms of mass percentage, Te is 0.4%, the sum of impurities is less than 0.1%, and the balance is Cu; the raw materials are electrolytic copper and copper-tellurium master alloy ingots, and the melting temperature is 1120 ° C;

[0100] (2) feeding argon into the flow channel through the inert gas inlet, and then discharging the first alloy melt o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com