Laminated glass

A technology of laminated glass and glass plate, applied in windshield, coating, glass/slag layered products, etc., can solve the problems of complex coating glass process, high equipment maintenance cost, harsh realization conditions, etc., and achieve good electromagnetic wave transmission. over-performance, excellent thermal insulation performance, and the effect of reducing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

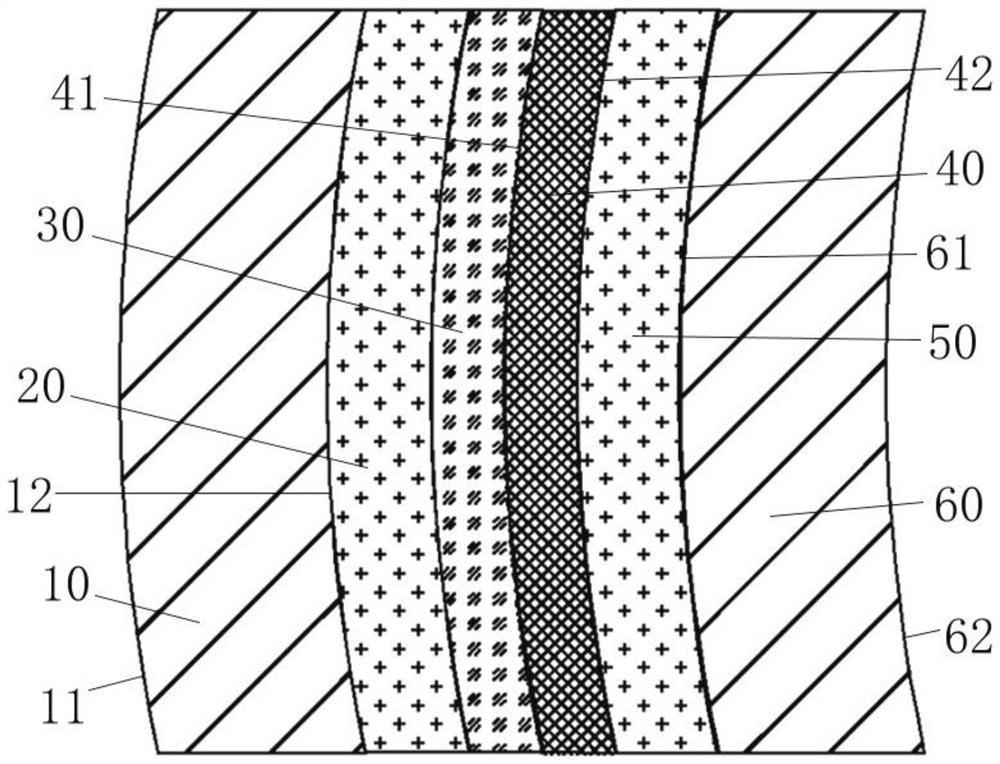

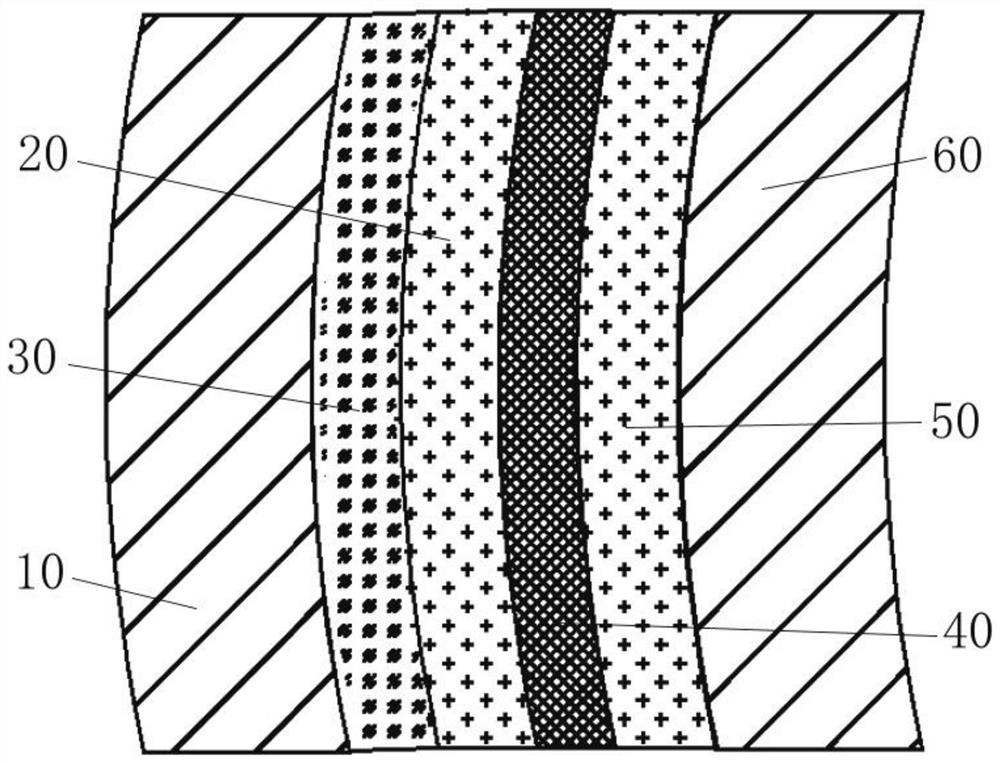

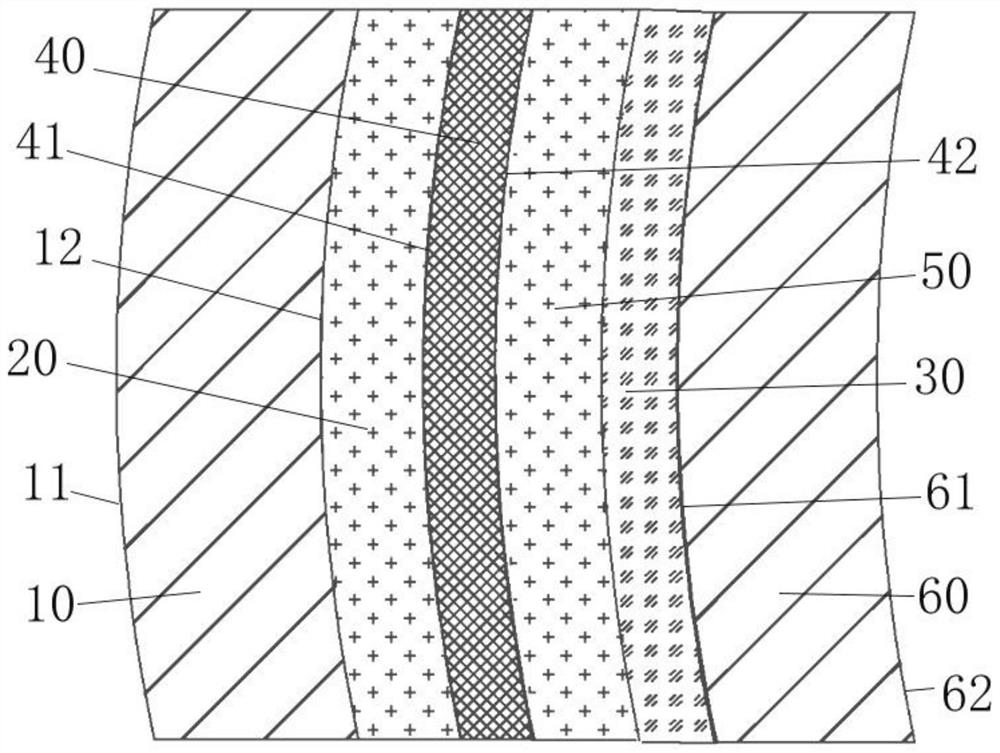

[0087] In the present invention, when the functional coating 30 in the laminated glass is located on the surface of the functional film 40, the preparation method of the laminated glass may include:

[0088] 1. Lay the functional film 40 on the curved glass plate, apply a functional coating on the surface of the functional film 40 away from the curved glass plate, and thermally cure to obtain a pre-formed functional film 40. The pre-formed functional film 40 has a second vertical radius of curvature;

[0089] 2. Laminate the preformed functional film with the inner glass plate 60 and the outer glass plate 10 having the first vertical radius of curvature in sequence to obtain a laminated glass.

Embodiment 1

[0100] Embodiment 1 provides a kind of laminated glass, and its preparation method comprises:

[0101] 1. Combine 10g chelating agent A, 70g silica sol C, 17g epoxy resin, 2g infrared absorber (Cs x WO 3 ) mixing, and after stirring evenly, the functional coating is obtained;

[0102] 2. Prepare a curved glass plate with a first vertical radius of curvature as the inner glass plate 60, and lay the functional film 40 on the curved glass plate (this curved glass plate is different from the inner glass plate 60, as in the following examples and comparative examples). ) on the convex surface of ), and then coating the functional coating on the first convex surface 41 of the functional film 40, and then thermally curing them together in an oven to obtain a preformed preformed coating with a second vertical radius of curvature coated with a functional coating The functional thin film 40 of 30, the thickness of the functional coating 30 is 3.2 μm. Wherein, the second vertical radi...

Embodiment 2

[0105] Embodiment 2 provides a kind of laminated glass, and its preparation method comprises:

[0106] 1. Mix 10g of chelating agent B, 70g of silica sol C, 17g of epoxy resin, and 2g of infrared absorber (Cs x WO 3 ) mixing, and after stirring evenly, the functional coating is obtained;

[0107] 2. Prepare a curved glass plate with a first vertical radius of curvature as the inner glass plate 60, lay the functional film 40 on the convex surface of the curved glass plate, and then coat the functional coating on the first convex surface 41 of the functional film 40, Then, they are thermally cured together in an oven to obtain a preformed functional film 40 having a second vertical radius of curvature and coated with a functional coating 30 with a thickness of 5.2 μm. Wherein, the second vertical radius of curvature is 75% of the first vertical radius of curvature.

[0108] 3. Take another curved glass plate with the first vertical radius of curvature as the outer glass plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap