Oil outlet control valve of electronic control oil injector

An oil control valve and electronically controlled fuel injection technology, which is applied to fuel injection devices, machines/engines, charging systems, etc., can solve the problems of decreased fuel injection accuracy, decreased oil pressure unloading speed, etc., so as to increase service life and reduce Hazardous, usefulness-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

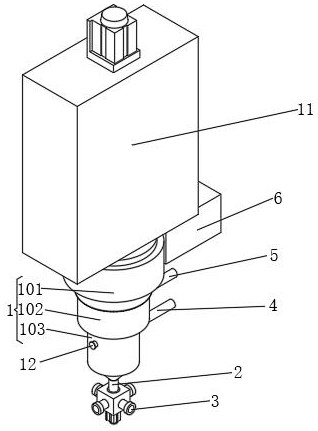

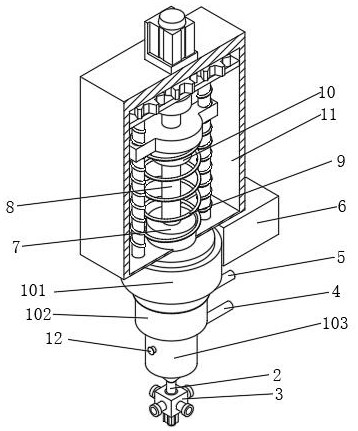

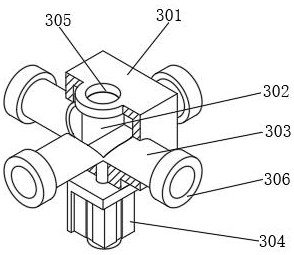

[0020] In a specific embodiment of the present invention, through the cooperative use of multiple components inside the invention, the pressure required to generate fuel injection can be injected at the correct time and the correct fuel injection quantity, and at the same time, the internal pressure of the valve body 1 can be controlled. The volume can be minimized, which improves the effect of fuel pressurization and the control of fuel injection quantity. Multiple pipelines are distributed, which increases the practicability of the oil outlet control valve. Through the setting of the oil discharge pipe 5, when the oil intake is too large, the excess fuel can be exported and recycled, which reduces the excessive fuel base. The harm to the oil outlet control valve, at the same time, through the coordinated use of the air pressure adjustment component 12, when the air pressure inside the control valve body 1 is too large, the pressure inside the control valve body 1 is reduced, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com