Open type current limiting reactor and manufacturing method thereof

A current-limiting reactor and the technology of its manufacturing method are applied in the directions of inductance/transformer/magnet manufacturing, transformer/reactor installation/support/suspension, transformer/inductor cooling, etc. Problems such as large ground area, to achieve the effect of reducing the overall weight, increasing the heat dissipation area, and saving land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

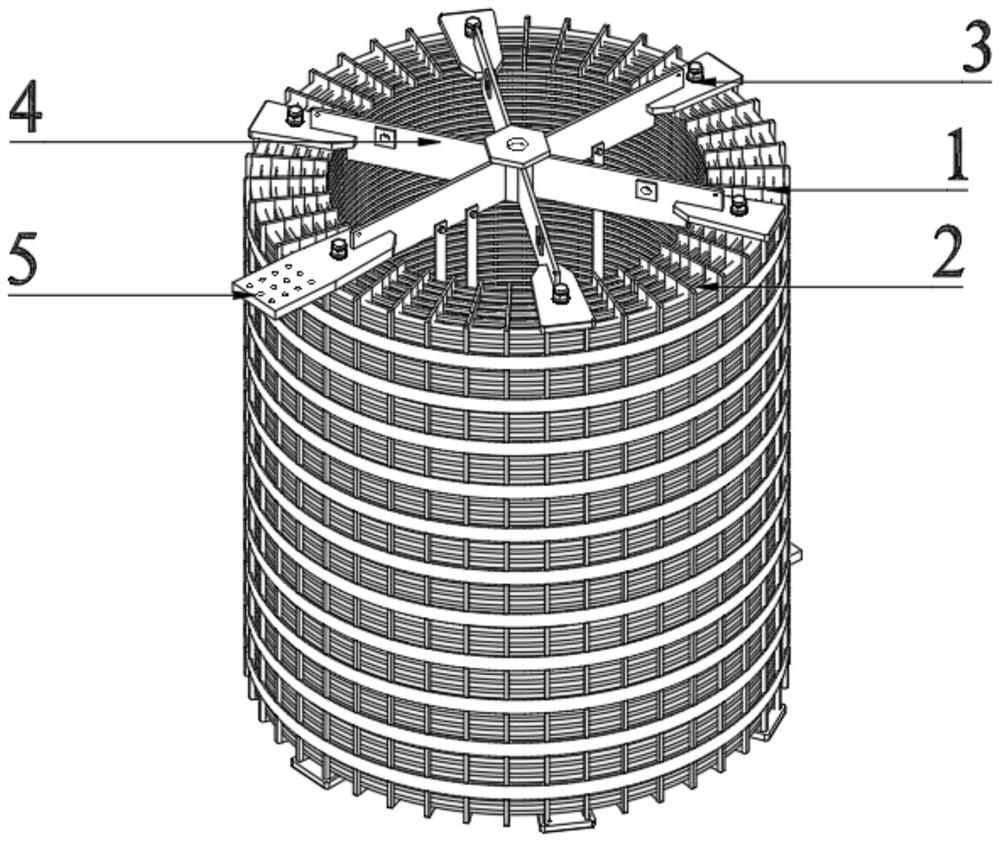

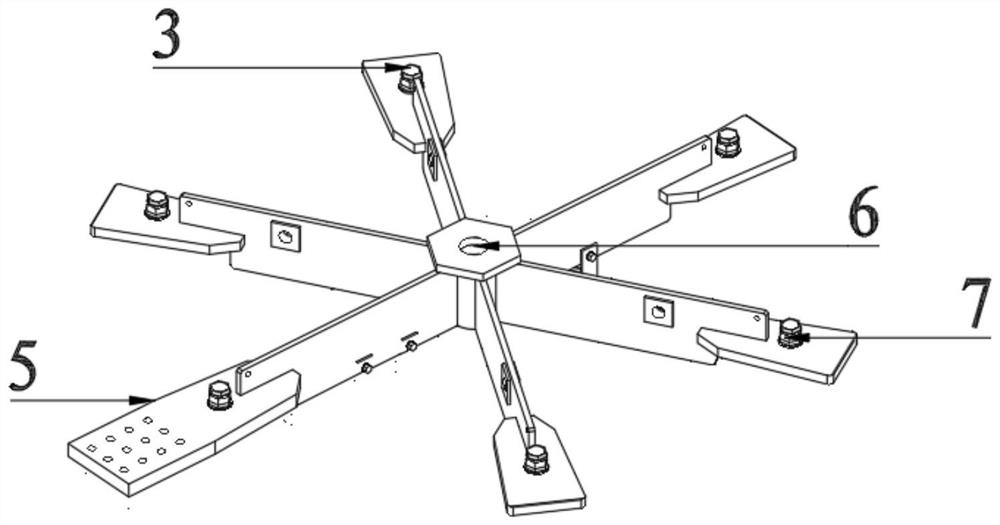

[0032] refer to Figure 1-Figure 3 , an open current-limiting reactor, including a winding and a coil clamping device; the winding includes a plurality of insulating plates 1 and coils, and a plurality of slots 1-1 for accommodating coils are evenly opened on the insulating plate 1; The coil is a bare duralumin flat wire 2, the bare duralumin flat wire 2 is horizontally wound on the slot 1-1 of the insulating plate 1, and the winding is connected with the coil clamping device to clamp and fix the winding. The insulating plate with serrated slot is used for fixing, and the heat dissipation area is increased; the coil is made of bare hard aluminum flat wire, because there is no insulating film wrapped, there is no need to worry about the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com