Corrosion liquid medicine spraying device and method for improving wafer liquid medicine corrosion uniformity

A technology of liquid medicine and wafer, applied in the direction of climate sustainability, sustainable manufacturing/processing, final product manufacturing, etc. The effect of stability, good fluidity of liquid medicine, and dynamic uniform corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

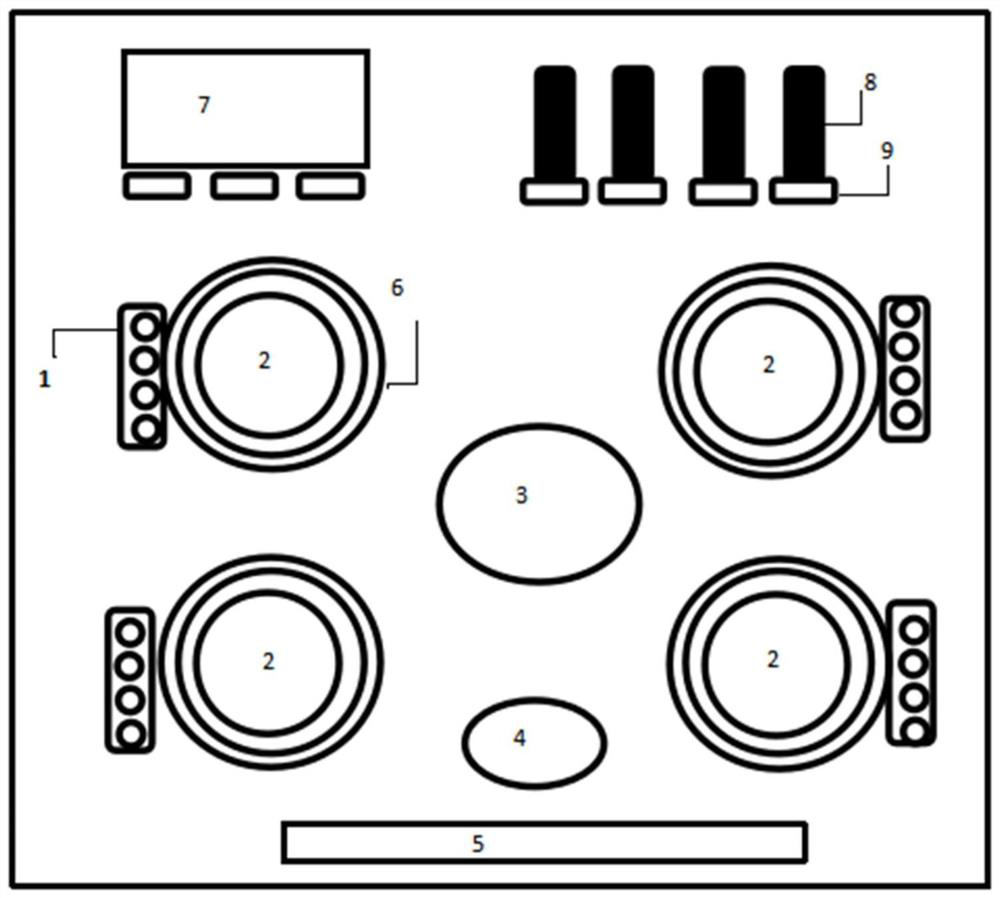

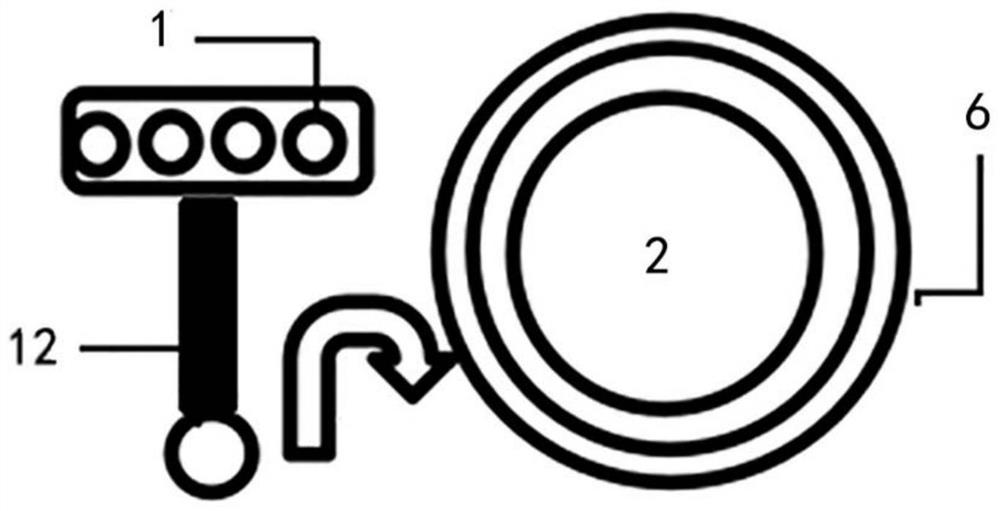

[0039] This embodiment provides a spraying device for corrosive liquid medicine, such as Figure 1-5 As shown, a machine control system 5 is included, and the machine control system 5 is respectively connected to the cassette module 4, the robot module 3, the 4 corrosion modules and the chemical supply module.

[0040] The machine control system 5 includes a central controller for controlling the cassette module 4, the robot module 3, a plurality of the corrosion modules and the chemical supply module to realize automatic control of the wafer corrosion process ;The central controller adopts win10 operating system and has a large-screen touch display screen to display the function execution of each module during the operation of the equipment, as well as display and modify process parameters, support MES interface Ethernet, MES system and equipment two-way mutual corresponding recipe management .

[0041] The cassette module 4 includes a cassette housing 10 , and a plurality o...

Embodiment 2

[0047] The present embodiment provides a method for improving the etching uniformity of the chemical solution of the wafer, using the device of the first embodiment, and using phosphoric acid to corrode the gallium nitride wafer, including the following steps:

[0048] (1) Heat the corrosion liquid in the liquid storage tank to the set temperature and set time, the temperature is 120°, and the liquid needs to be heated at 120° for 6 hours before it can be operated. After the liquid medicine is ready, the machine control system controls the robot module to sequentially take out the wafers from the metal jam and place them in the centering device for centering, and then transfer the centered wafers to the horizontal suction cups of each corrosion module one by one.

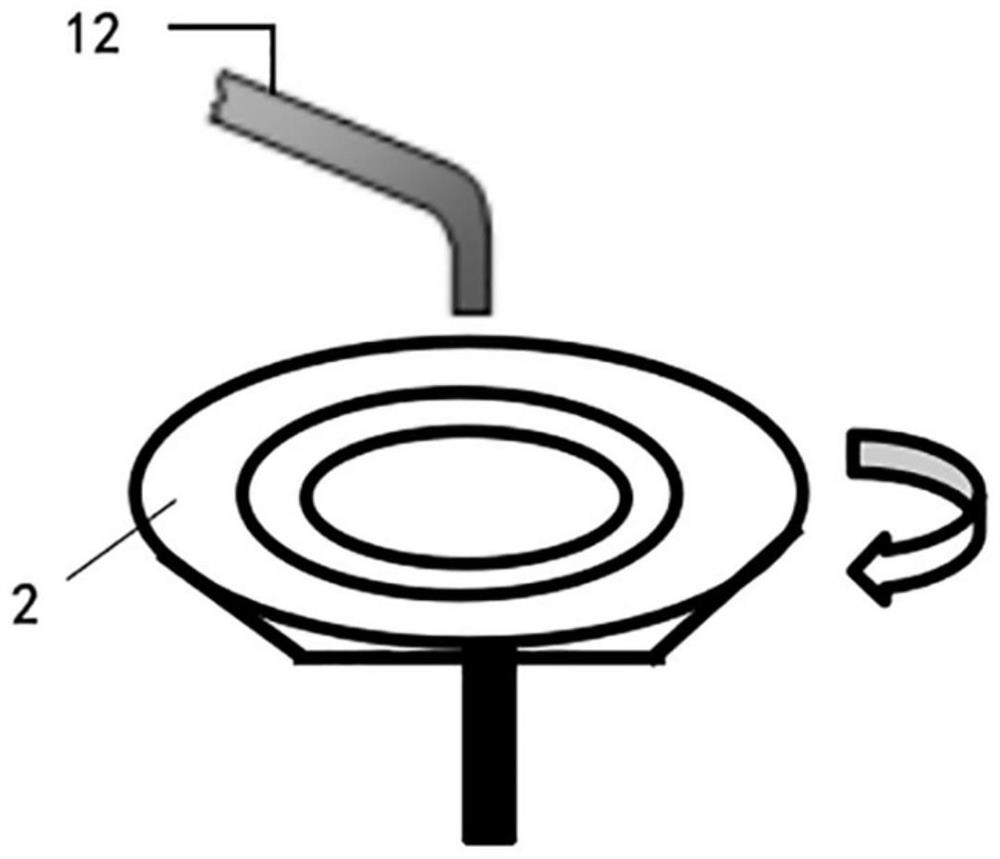

[0049] (2) There are 4 corrosion units in the device, which can work at the same time. The specific operations are: start the rotating motor to make the rotation speed of the horizontal suction cup reach 1500rpm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com