Variable channel algan/gan HEMT structure and preparation method

A channel and variable technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as inability to obtain uniform electric field distribution, avoid premature breakdown and failure, and improve withstand voltage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

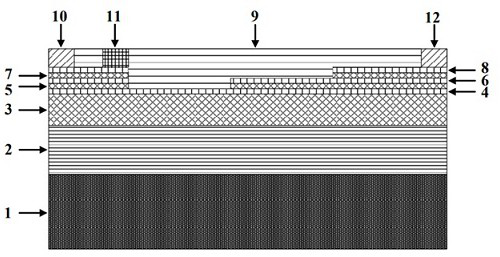

[0049] The present invention will be described in further detail below with reference to the accompanying drawings and specific preferred embodiments.

[0050] like figure 1 As shown, a variable channel AlGaN / GaN HEMT structure includes a substrate layer 1, a buffer layer 2, n Set of GaN / AlGaN heterojunction stack, passivation layer 9 , source electrode 10 , gate electrode 11 and drain electrode 12 .

[0051] The material of the above-mentioned substrate layer is preferably silicon, sapphire, gallium nitride or silicon carbide.

[0052] The above buffer layer is epitaxially grown on the top of the substrate layer, preferably a GaN material with a thickness of 2-6 microns.

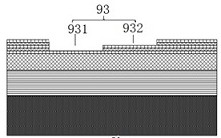

[0053] n The group GaN / AlGaN heterojunction stacks are epitaxially grown on top of the buffer layer from bottom to top, and from bottom to top are the first group of GaN / AlGaN heterojunction stacks, the second group of GaN / AlGaN heterojunction stacks, ..., the first n Group GaN / AlGaN heterojunction sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com