Cubic press and automatic temperature control adjusting method thereof

A six-sided top press and temperature control technology, which is applied in the direction of temperature control by electric means, auxiliary controller with auxiliary heating device, and ultra-high pressure application process, etc., can solve the sintering temperature difference, six-sided top The problems of low intelligence in temperature control of the press can achieve the effect of large deviation of sintering temperature, avoiding random manual control and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

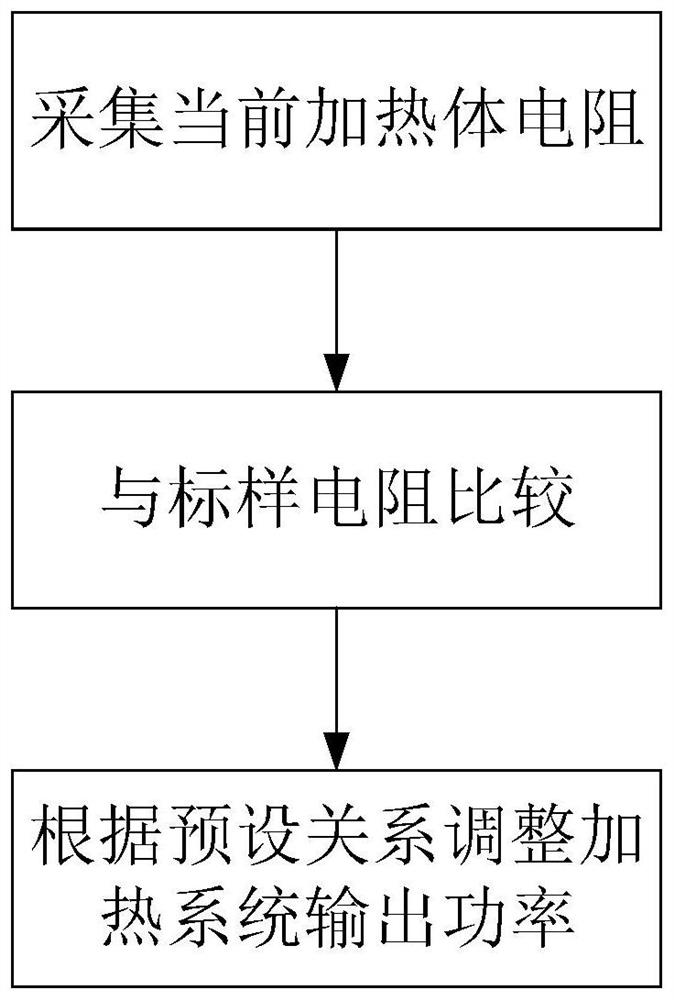

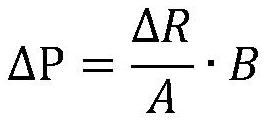

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] Six-sided top press embodiment:

[0043] A six-sided top press of the present invention, comprising a heating system, the output power (current) of the heating system is heated by a heating body having a certain resistance value within the pyrophyll synthesis block, to achieve heating of the mixed powder during the extrusion process.

[0044] The heat Q required to synthesize diamond or other superhard materials 需 Yes, so the heating system is heated with a constant power (output power P). Since there is a loss of heat during heating, Q 需 =αQ 总 ,Q 总 It is the total heat generated by the six-sided top press, which is generated by the output power P of the heating system, which is:

[0045] Q 需 =αQ 总 =αPT=αI 2 RT

[0046] Wherein, T is the heating time of the heating system, I is the constant current output under the working voltage of the heating system, R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com