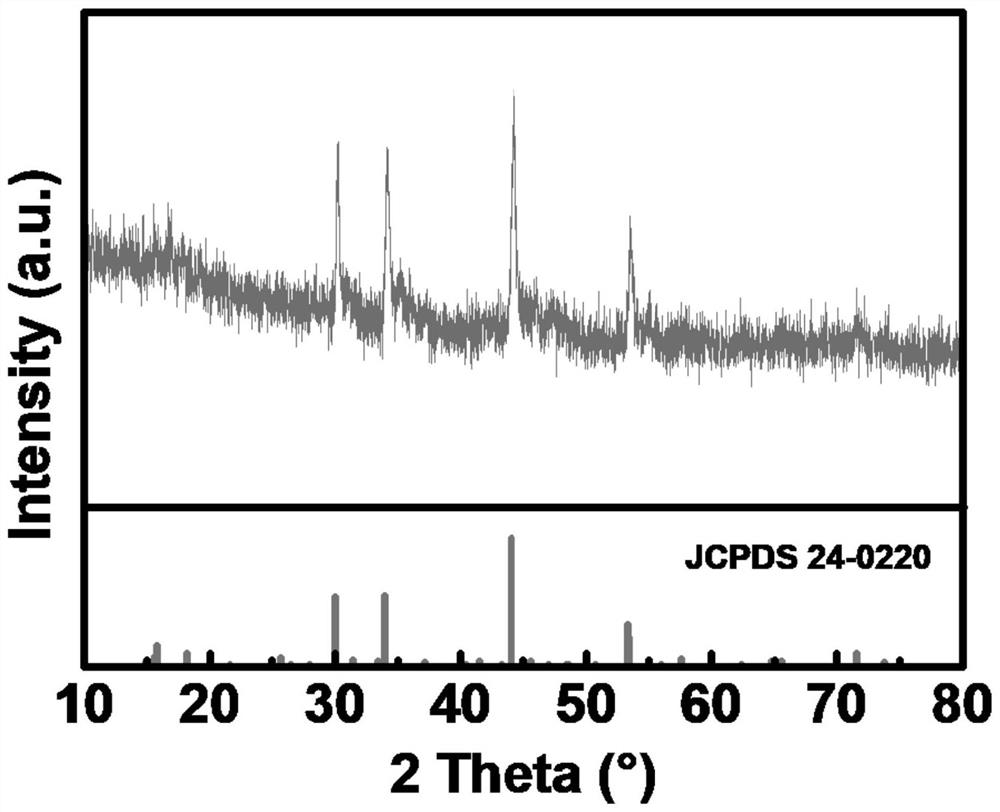

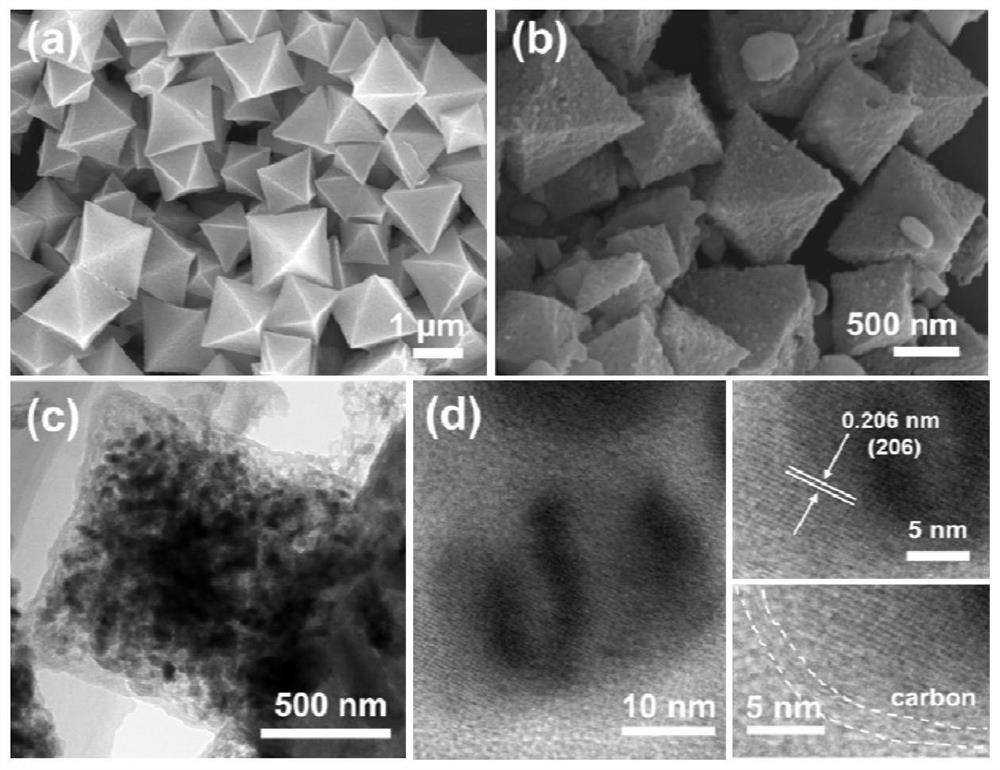

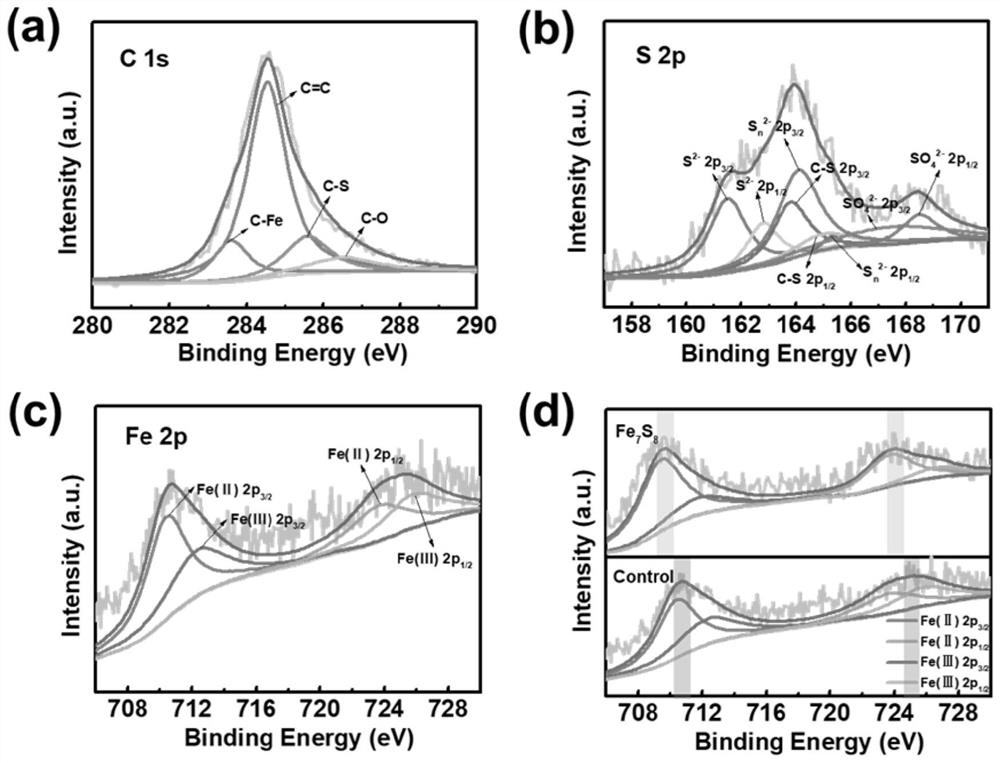

Preparation method and application of sulfur-doped carbon skeleton coated heptairon octasulfide nanoparticle double-reaction-center Fenton-like catalyst

A technology of carbon skeleton and sulfur doping, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve problems such as poor stability, easy agglomeration reaction pH range, metal ion leaching, etc., and reach the pores High efficiency, improved dispersion and stability, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: The present embodiment of a sulfur-doped carbon skeleton wrapped eight sulfide heptaferros nanoparticles double reaction center Fenton catalyst preparation method, is completed according to the following steps:

[0032] First, the terephthalic acid and FeCl 3 ·6H 2 O was added to N, N-dimethylformamide, stirred, to give solution I.;

[0033] Second, the solution I. transferred to the hydrothermal reactor, and then at 110 ° C ~ 160 ° C for hydrothermal reaction, the reaction ended, to obtain an orange-yellow solution;

[0034]Third, the use of N, N-dimethylformamide and absolute ethanol on the orange-yellow solution repeatedly washed until the solution of the supernatant colorless, and then dried, to obtain MIL-101 (Fe) precursor;

[0035] Fourth, the MIL-101 (Fe) precursor is placed on one side of the porcelain boat, the other side is added with sublimation sulfur powder, and then covered with a porcelain boat, and there are gaps on both sides of th...

specific Embodiment approach 2

[0037] Specific embodiment two: The present embodiment and the specific embodiment of a difference is: the mass of terephthalic acid described in step one to N, N- dimethylformamide volume ratio of (0.4g ~ 0.5g) :(40mL ~ 60mL); FeCl as described in Step 1 3 ·6H 2 The volume ratio of O mass to N,N-dimethylformamide is (1.3g~1.6g):(40mL~60mL). Other steps are the same as the specific embodiment.

specific Embodiment approach 3

[0038] Specific embodiment three: the present embodiment and one or two of the specific embodiments are different from: the stirring time described in step one is 1h ~ 2h, the speed of stirring is 800r / min ~ 1000r / min. Other steps are the same as the specific embodiment one or two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com