Rock core sampling device for directional branch drilling

A technology of core sampling and directional branching, which is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems of slow drilling process, unsuitable depth sampling, easy falling off of core pipes, etc., and achieves novel structure, It is not easy to be stuck, and the impact and crushing range is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

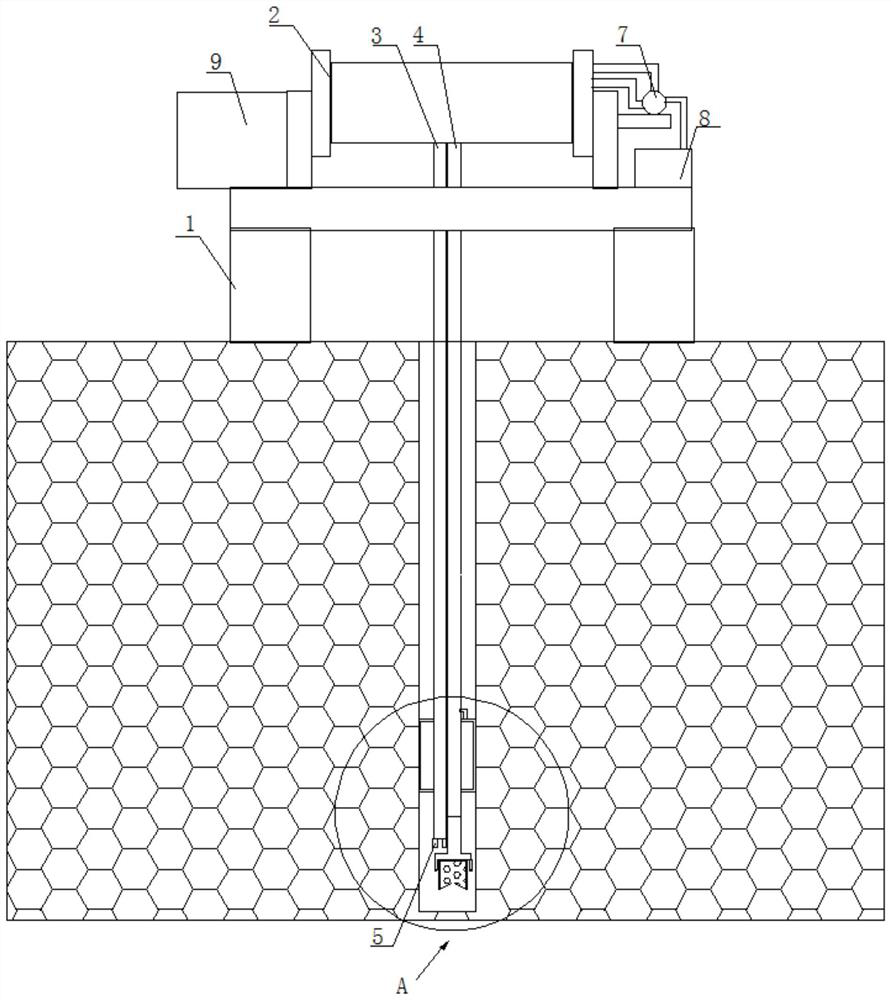

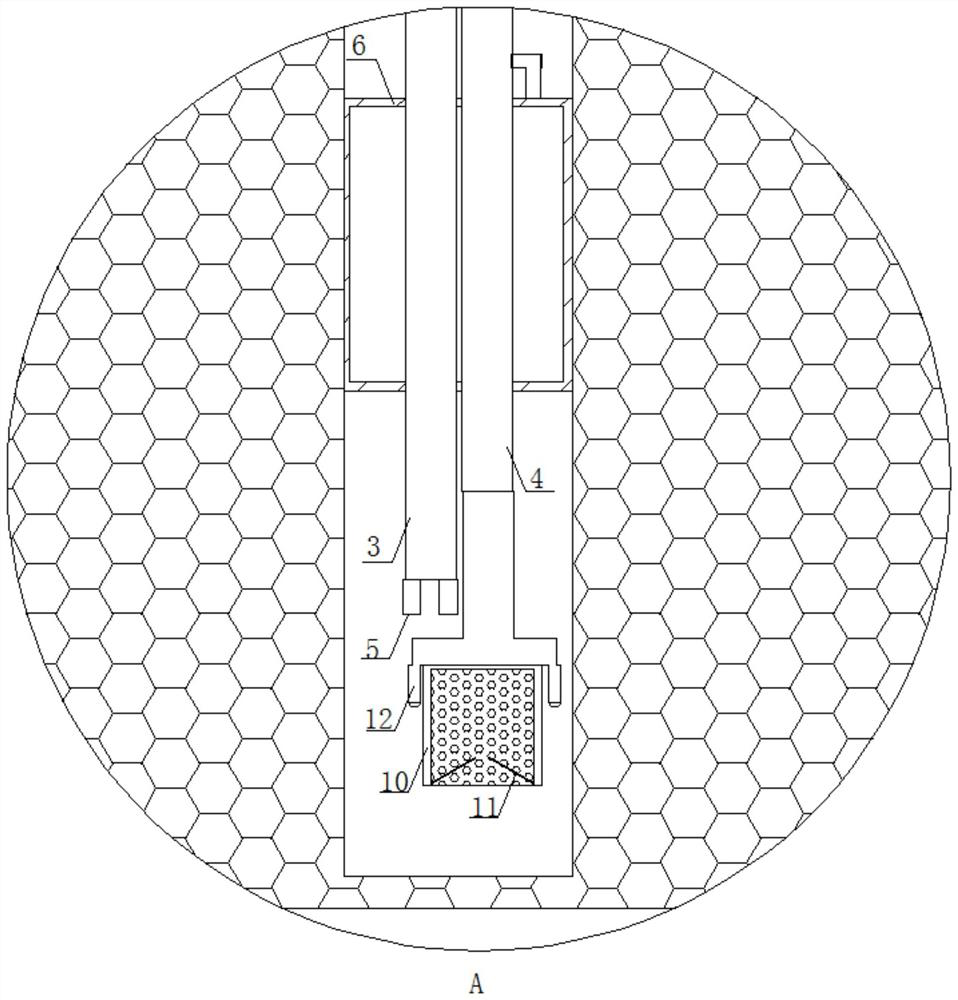

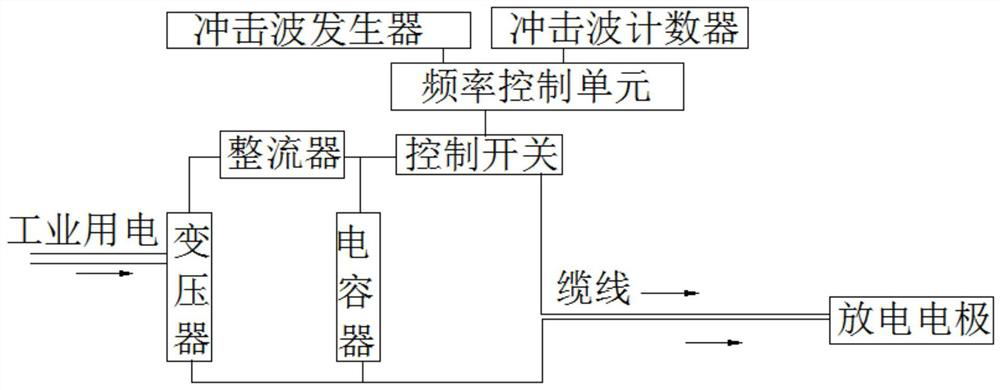

[0042] like Figures 1 to 4 As shown, the present embodiment provides a core sampling device for directional branch drilling, including a mobile workbench 1 arranged on the drilling hole, and a hydroelectric impact crushing unit and a sample recovery unit are arranged on the mobile workbench 1, The hydraulic-electric impact crushing unit includes a cable release assembly set on the mobile workbench 1, and the cable release assembly includes a motor-driven pay-off wheel 2 set on the mobile workbench 1. The pay-off wheel 2 is provided with cables 3 side by side. and the conveying hose 4, the mobile workbench 1 is provided with a drilling temporary blocking unit that accompanies the cable 3 to descend, and the mobile workbench 1 is provided with a charging optoelectronic component connected to the cable 3, and the end of the cable 3 is provided with Discharge electrodes 5 are provided. The drilling temporary plugging unit includes an inflation airbag 6 arranged at the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com