Analysis method of ambam

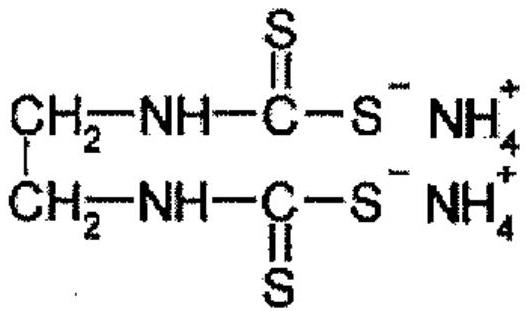

An analysis method, the technology of disenium, which is applied in the field of disenium, can solve the problems of not establishing a direct analysis method of disenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

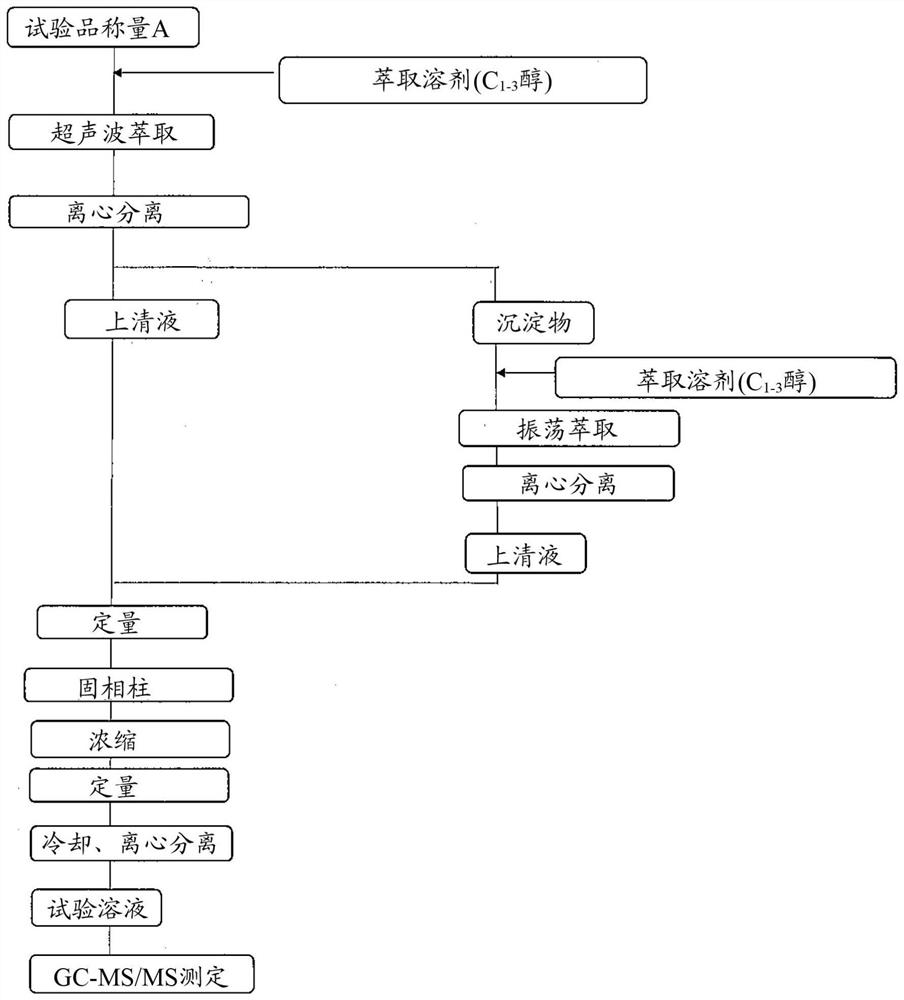

Method used

Image

Examples

Embodiment 1

[0053] Accurately weigh 1.0g of ginseng powder, put it into a centrifuge precipitation tube, add 10ml of ethanol, and perform ultrasonic extraction at below 20°C for 10 minutes. After that, centrifugation was performed for 5 minutes, and the supernatant was taken out. 10 ml of ethanol was added to the residue, extracted by shaking for 15 minutes, centrifuged again for 5 minutes, the supernatant was combined with the above-mentioned supernatant, and the volume was accurately adjusted to 25 ml with ethanol as the extraction solution.

[0054] Discovery manufactured by SIGMA-ALDRICH Co., Ltd. activated with ethanol in advance TM DSC-NH 2 10 ml of the extraction solution was placed in the SPE tube and allowed to flow out, followed by 10 ml of ethanol. The obtained effluent was concentrated under reduced pressure at 40°C, and the volume was accurately adjusted to 2 ml with ethanol. After standing at 0-5°C for 30 minutes or more, high-speed centrifugation was performed for 3 mi...

Embodiment 2

[0074] Accurately weigh 1.0g of ginseng powder, put it into a centrifugal precipitation tube, and add 10ml of extraction solvent, the extraction solvent is a solvent pre-added with EDTA and sodium sulfate in ethanol and left overnight, and ultrasonically extracted at below 20 ° C for 10 minutes . Then, centrifugation was performed for 5 minutes, and the supernatant was collected. 10ml of extraction solvent was added to the residue, extracted with shaking for 15 minutes, centrifuged again for 5 minutes, the supernatant was combined with the above-mentioned supernatant, and the volume was accurately adjusted to 25ml with the extraction solvent as the extraction solution.

[0075] Discovery manufactured by SIGMA-ALDRICH Co., Ltd. activated with ethanol in advance TM DSC-NH 2 10 ml of the extraction solution was placed in the SPE tube and allowed to flow out, followed by 10 ml of ethanol. 5 ml of the obtained effluent was concentrated under reduced pressure at 40°C, and the v...

Embodiment 3

[0091] Accurately weigh 1.0 g of yam powder, put it into a centrifugal precipitation tube, and add 10 ml of an extraction solvent, which is a solvent pre-added with EDTA and sodium sulfate in ethanol and left overnight, and ultrasonically extracted for 10 minutes at below 20°C . Then, centrifugation was performed for 5 minutes, and the supernatant was collected. 10ml of extraction solvent was added to the residue, extracted with shaking for 15 minutes, centrifuged again for 5 minutes, the supernatant was combined with the above-mentioned supernatant, and the volume was accurately adjusted to 25ml with the extraction solvent as the extraction solution.

[0092] Discovery manufactured by SIGMA-ALDRICH, which is preactivated with ethanol TM DSC-NH 2 10 ml of the extraction solution was placed in the SPE tube and allowed to flow out, followed by 10 ml of ethanol. 5 ml of the obtained effluent was concentrated under reduced pressure at 40°C, and the volume was accurately adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com