Lithium-rich manganese-based layered material with sulfur-doped surface and lithium sulfate protective layer

A technology rich in lithium manganese and lithium sulfate, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of capacity and stability to be further improved, high concentration of sulfur vapor, complex process operation, etc., to improve the rate performance and Discharge capacity, increased ion transport, and the effects of alleviating side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Grind the elemental sulfur powder in anhydrous ethanol and disperse it uniformly, and then add the lithium-rich manganese-based layered material Li 1.2 Mn 0.6 Ni 0.2 O 2 , after ultrasonically dispersing uniformly, heating to 70 °C with stirring to evaporate to dryness, and vacuum drying at 80 °C for 12 h to obtain an intermediate product; wherein, the molar ratio of elemental sulfur powder to lithium-rich manganese-based cathode material is 0.03:1;

[0039] (2) Under the oxygen atmosphere in the tube furnace, the oxygen flow rate is 80mL / min, and the intermediate product is calcined at 270°C for 8h, and the heating rate is 10°C / min to obtain a surface sulfur-doped and protected by lithium sulfate layer of Li-rich manganese-based layered material.

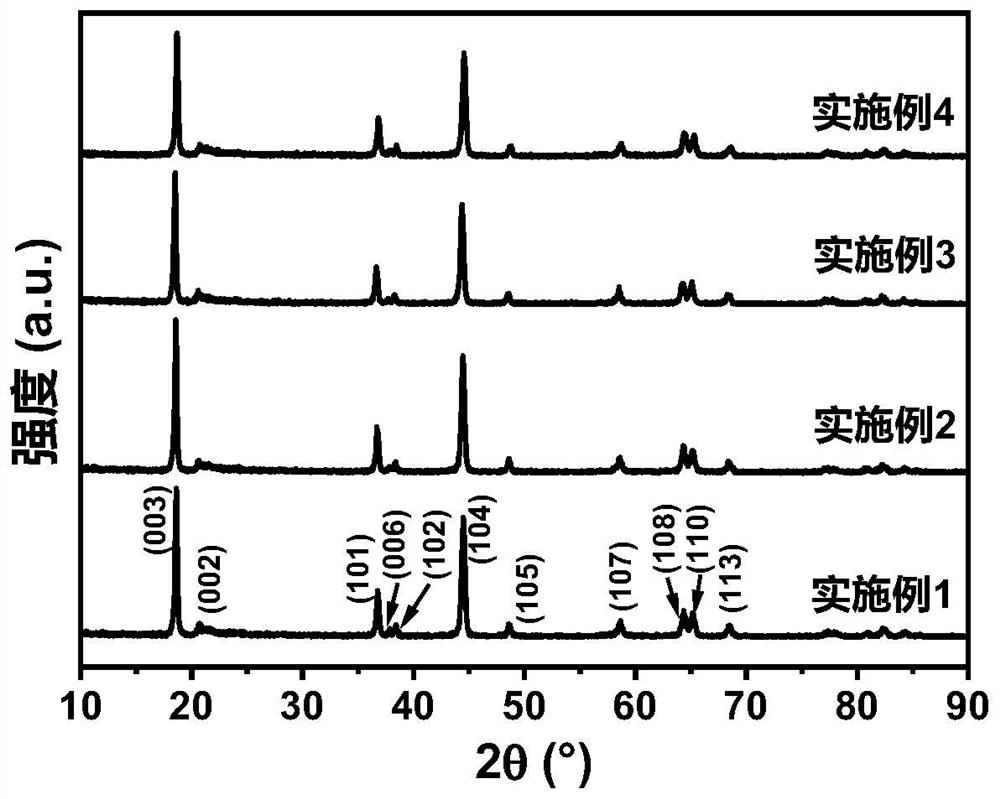

[0040] The XRD test results of the material are as follows figure 1 As shown, the characteristic peak positions of the material are similar to those of LiNiO 2 and Li 2 MnO 3 The characteristic peaks are consisten...

Embodiment 2

[0046] (1) Grind the elemental sulfur powder in anhydrous ethanol and disperse it uniformly, and then add the lithium-rich manganese-based layered material Li 1.2 Mn 0.6 Ni0.2 O 2 , after ultrasonically dispersing uniformly, heating to 70 °C with stirring to evaporate to dryness, and vacuum drying at 80 °C for 12 h to obtain an intermediate product; wherein, the molar ratio of elemental sulfur powder to lithium-rich manganese-based cathode material is 0.03:1;

[0047] (2) Under the oxygen atmosphere in the tube furnace, the oxygen flow rate is 100mL / min, and the intermediate product is calcined at 270°C for 6h, and the heating rate is 7°C / min to obtain a surface doped with sulfur and protected by lithium sulfate. layer of Li-rich manganese-based layered material.

[0048] The XRD test results of the material are as follows figure 1 As shown, the characteristic peak positions of the material are similar to those of LiNiO 2 and Li 2 MnO 3 The characteristic peaks are consi...

Embodiment 3

[0055] (1) Grind the elemental sulfur powder in anhydrous ethanol and disperse it uniformly, and then add the lithium-rich manganese-based layered material Li 1.2 Mn 0.6 Ni 0.2 O 2 , after ultrasonically dispersing uniformly, heating to 70 °C with stirring to evaporate to dryness, and vacuum drying at 80 °C for 12 h to obtain an intermediate product; wherein, the molar ratio of elemental sulfur powder to lithium-rich manganese-based cathode material is 0.03:1;

[0056] (2) Under the oxygen atmosphere in the tube furnace, the oxygen flow rate is 80mL / min, and the intermediate product is calcined at 270°C for 8h, and the heating rate is 10°C / min to obtain a surface sulfur-doped and protected by lithium sulfate layer of Li-rich manganese-based layered material.

[0057] The XRD test results of the material are as follows figure 1 As shown, the characteristic peak positions of the material are similar to those of LiNiO 2 and Li 2 MnO 3 The characteristic peaks are consisten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com