A kind of petrochemical wastewater treatment method based on heterogeneous catalytic ozone oxidation

A heterogeneous catalysis, petrochemical wastewater technology, applied in the oxidation water/sewage treatment, natural water treatment, multi-stage water treatment and other directions, can solve the problems of poor treatment effect, poor stability of metal oxides, low recovery rate, etc. Achieve the effect of improving treatment efficiency, saving costs, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

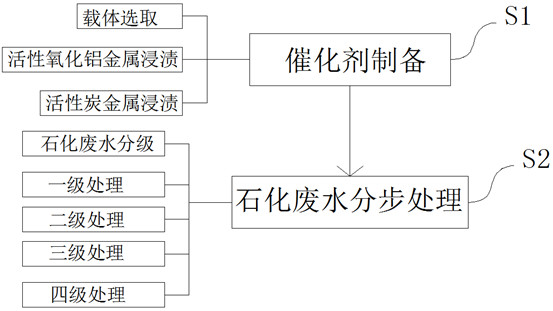

[0034] A petrochemical wastewater treatment method based on heterogeneous catalytic ozone oxidation, comprising the following steps:

[0035] S1, catalyst preparation:

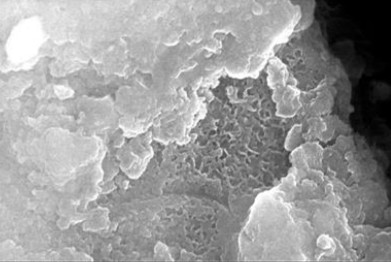

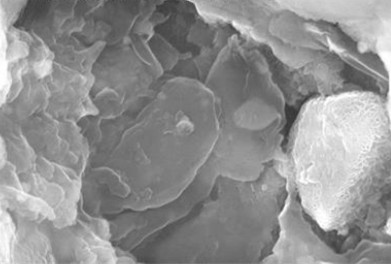

[0036] S1-1, carrier selection: select activated alumina and activated carbon as the carrier of the catalyst, and the activated alumina is γ-Al 2 O 3The activation method of activated alumina is as follows: the alumina is washed with deionized water for 3 times, then soaked in a hydrochloric acid solution with a concentration of 0.1 mol / L for activation for 2 h, and dried to obtain activated alumina. The weight of activated alumina and activated carbon The ratio is 3:1, and the activated alumina and activated carbon are ground separately, so that the particle size of the activated alumina is 5mm, and the particle size of the activated carbon is 6mm;

[0037] S1-2. Activated alumina metal impregnation: pour the mixed metal impregnant composed of copper nitrate and manganese nitrate into the impregnation tank,...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, and the difference lies in:

[0048] In S1-1, activated alumina is α-Al 2 O 3 , The activation method of activated alumina is as follows: the alumina is washed with deionized water for 3 times, then soaked in a hydrochloric acid solution with a concentration of 0.2mol / L for activation for 2h, and dried to obtain activated alumina. The weight of activated alumina and activated carbon The ratio is 3:1, and the activated alumina and activated carbon are ground separately so that the particle size of the activated alumina is 8 mm and the particle size of the activated carbon is 10 mm.

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, and the difference lies in:

[0051] In S1-1, the activated alumina and the activated carbon were respectively ground so that the particle size of the activated alumina was 6 mm and the particle size of the activated carbon was 8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com