Preparation method of metal microneedle array and polymer microneedle patch

A microneedle array and polymer technology, applied in metal processing equipment, non-active components of polymer compounds, medical preparations with non-active components, etc. The problem of low precision of microneedle, to achieve the effect of strong flexibility, good uniformity and high aspect ratio

Pending Publication Date: 2022-06-21

浙江德清娃哈哈科技创新中心有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In view of the problems of low microneedle precision, low flatness, and difficult control of uniformity in metal microneedle arrays prepared by existing processing methods, the purpose of the present invention is to provide a method for preparing metal microneedle arrays, which is not only relatively easy to realize Array production of metal microneedles, and the obtained metal microneedles have high precision, high flatness and good uniformity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

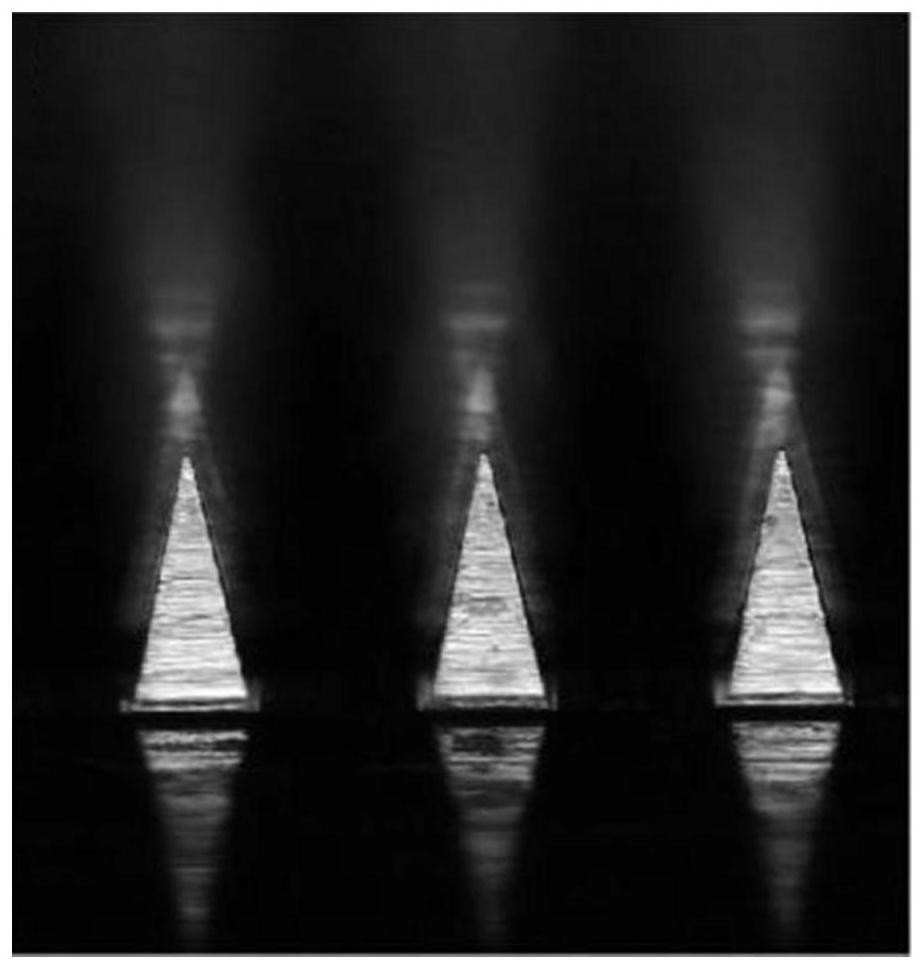

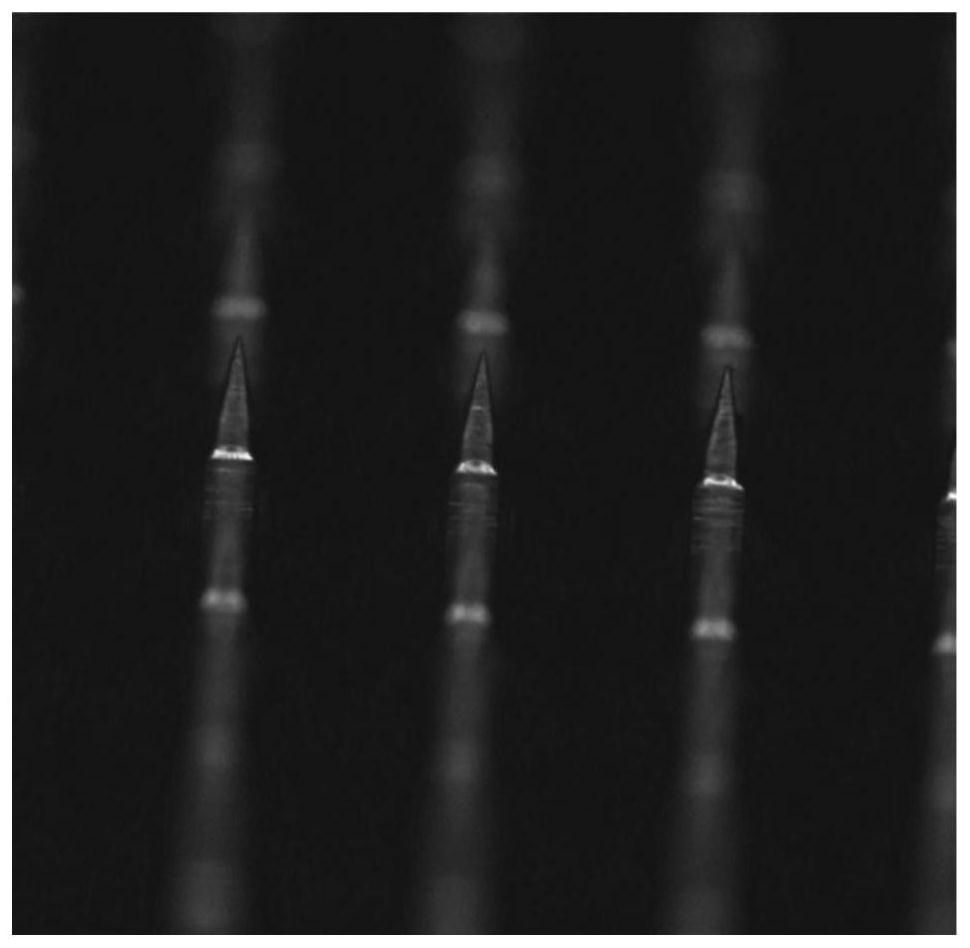

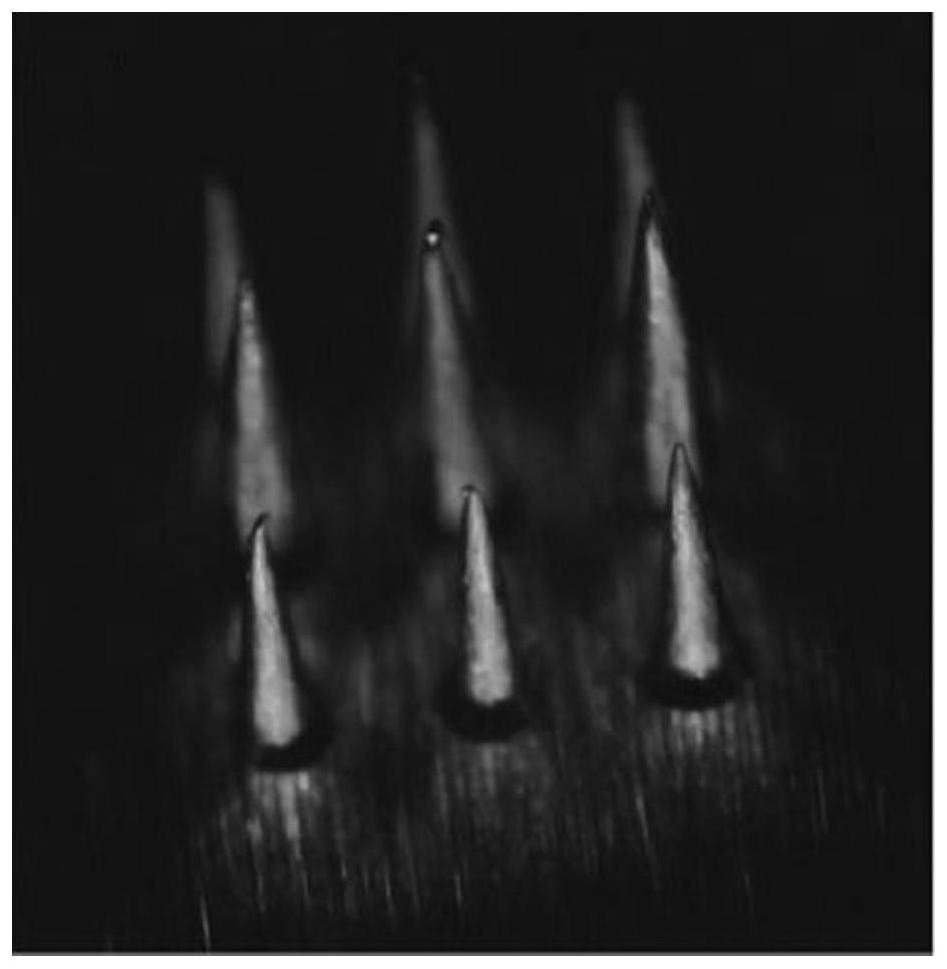

The invention relates to the technical field of microneedle preparation, and discloses a preparation method of a metal microneedle array and a polymer microneedle patch, the metal microneedle array is prepared through a PG optical grinding or metal probe welding method, and the depth-to-width ratio of the metal microneedle array prepared through PG optical grinding is high. The metal microneedles are good in repeatability, precision, average degree and uniformity, meanwhile, the problem that a large needle distance is needed when a single microneedle is ground is solved, and the method has the advantages that the speed is high, efficiency is high, and batch production of the metal microneedle array is easy to achieve. A microneedle main template is prepared by adopting a metal probe welding method, so that the length, the form and the overall array shape of each microneedle can be conveniently changed. The polymer microneedle patch template is prepared by adopting a die combination scheme, the preparation and forming of microneedles in various shapes can be realized on the basis of not modifying the shape of a metal array, and the method has the advantages of low cost, high efficiency, high flexibility and the like.

Description

technical field [0001] The invention relates to the technical field of microneedle preparation, in particular to a method for preparing a metal microneedle array and a polymer microneedle patch. Background technique [0002] As a new type of transdermal drug delivery technology, microneedles have attracted widespread attention in the fields of medical aesthetics and medicine due to their advantages of high efficiency, painlessness, and ease of application. Microneedles are applied to the surface of the skin to form micro / nano channels on the surface of the skin, enhance the permeability of the skin surface, and promote the entry of active substances / drugs inside or coated on the surface of the microneedles into the skin, thereby exerting the functions of these molecules; or The microneedles are only used as a tool to create channels that enhance the penetration of subsequently applied substances like within the skin. [0003] Microneedles made of metal materials through mic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C39/10A61K9/00A61K39/00A61K45/00A61K47/32A61K47/34A61K47/36A61K47/42A61M37/00B21G1/08B24B37/04B29B11/00B29C33/38B29L31/00

CPCB29C39/10B29C33/3842B21G1/08B29B11/00A61M37/0015A61K9/0021A61K47/34A61K47/32A61K47/36A61K47/42A61K45/00A61K39/00B24B37/042A61M2037/0023A61M2037/0046A61M2037/0053B29L2031/7544

Inventor 潘书婷游卫龙崔雪

Owner 浙江德清娃哈哈科技创新中心有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com