High-density high-strength fracturing propping agent and preparation method thereof

A fracturing proppant and high-strength technology, which is applied in chemical instruments and methods, earth drilling, sustainable manufacturing/processing, etc., can solve the problem that oil (gas) production cannot be effectively increased and the flow conductivity of fracturing proppant is reduced , high pressure and strong anti-breaking ability can not reach and other problems, to achieve the effect of improving oil extraction efficiency, increasing density, and enhancing compressive strength

Active Publication Date: 2022-06-21

YANGQUAN XINGTAO FRACTURING PROPPING AGENT CO LTD

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

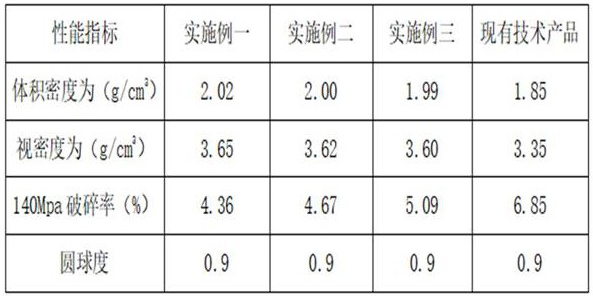

[0003] In the prior art, fracturing proppants with medium-low density and medium-low strength are often used, but the high-pressure and crushing resistance of such low-medium-density and medium-low-strength products is far from meeting the requirements of actual work, resulting in fracturing support The diversion capacity of the agent is reduced, and the oil (gas) production cannot be effectively increased, which does not help the oil (gas) production to increase the production demand

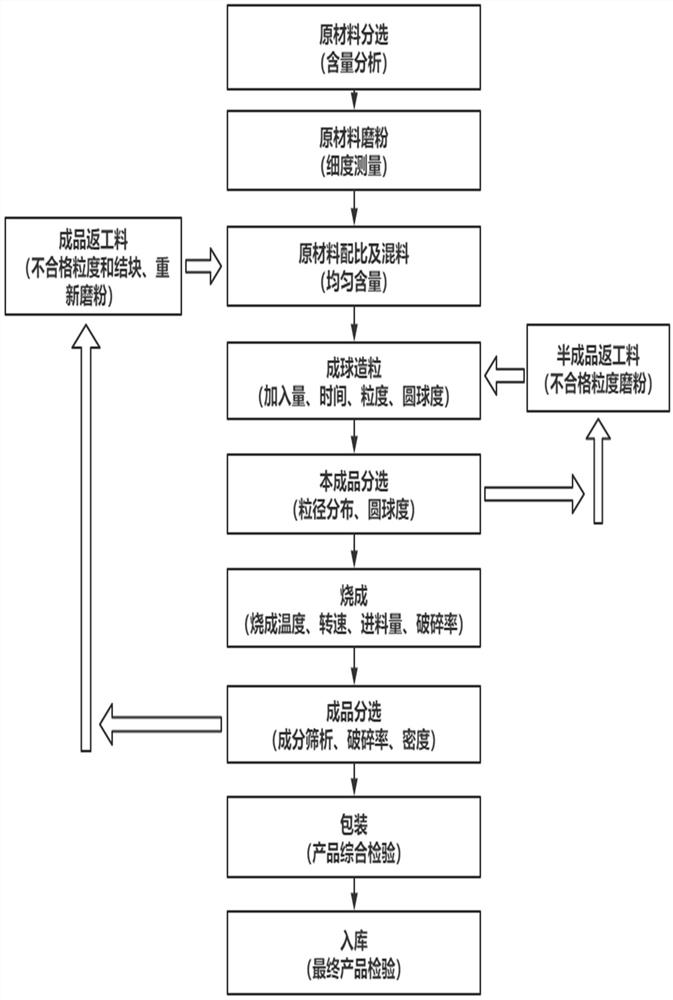

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the technical field of fracturing propping agent production, in particular to a high-density and high-strength fracturing propping agent and a preparation method thereof. The raw materials comprise 86.5%-90.5% of light calcined bauxite, 4%-8% of raw bauxite and 3.5%-7% of an additive; the light-burned bauxite is obtained by carrying out light burning on raw bauxite, so that the content of Al2O3 is increased to 90% or above, the content of SiO2 is reduced to 2% or below, the content of Fe2O3 is reduced to 1% or below, and the content of TiO2 is increased to 3% or above; the burning vector of the light burning bauxite is 33%-34%. According to the invention, the ingredients are simple, and the high-temperature reaction is more complete under the combined action of the light-burned bauxite, the raw bauxite, the additive MnO2 and the dolomite powder. The fracturing propping agent can break through the density limit of a traditional medium-low density fracturing propping agent and improve the density of a product, so that the compressive strength of the product and the flow guide performance of formation cracks are enhanced, the oil exploitation efficiency is improved, and the oil yield is increased.

Description

technical field [0001] The invention relates to the technical field of fracturing proppant production, and more specifically, to a high-density, high-strength fracturing proppant and a preparation method thereof. Background technique [0002] Fracturing proppant is an essential support material required for hydraulic fracturing technology during oil (gas) exploitation. During oil and gas deep well mining, high closure pressure and low permeability deposits are treated by fracturing to crack the oil-gas-bearing rock formations, and oil and gas are collected from the channels formed by the fractures. At this time, fluids need to be injected into the rock base to overcome formation fractures Intensive pressure creates cracks in the rock formations around the wellbore, forming a channel with high-level flow capability. In order to keep the cracks formed after fracturing open, oil and gas products can pass through smoothly. Petroleum fracturing proppant is used along with the hi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K8/80

CPCC09K8/80Y02P20/10

Inventor 鲍亚祥尹洪祥

Owner YANGQUAN XINGTAO FRACTURING PROPPING AGENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com