Pull-rod-free construction formwork for slab culvert wall body

A technology without tie rods and slabs and culverts, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve water leakage, roadbed diseases, Affect the appearance quality of concrete and other issues, achieve the effect of strong practicability, guarantee the support effect, and avoid roadbed diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

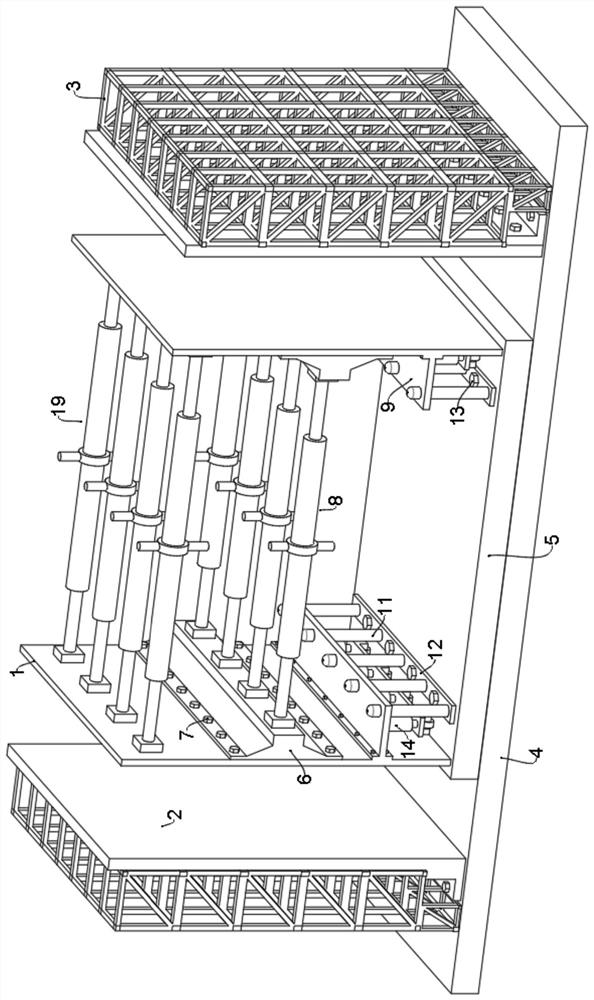

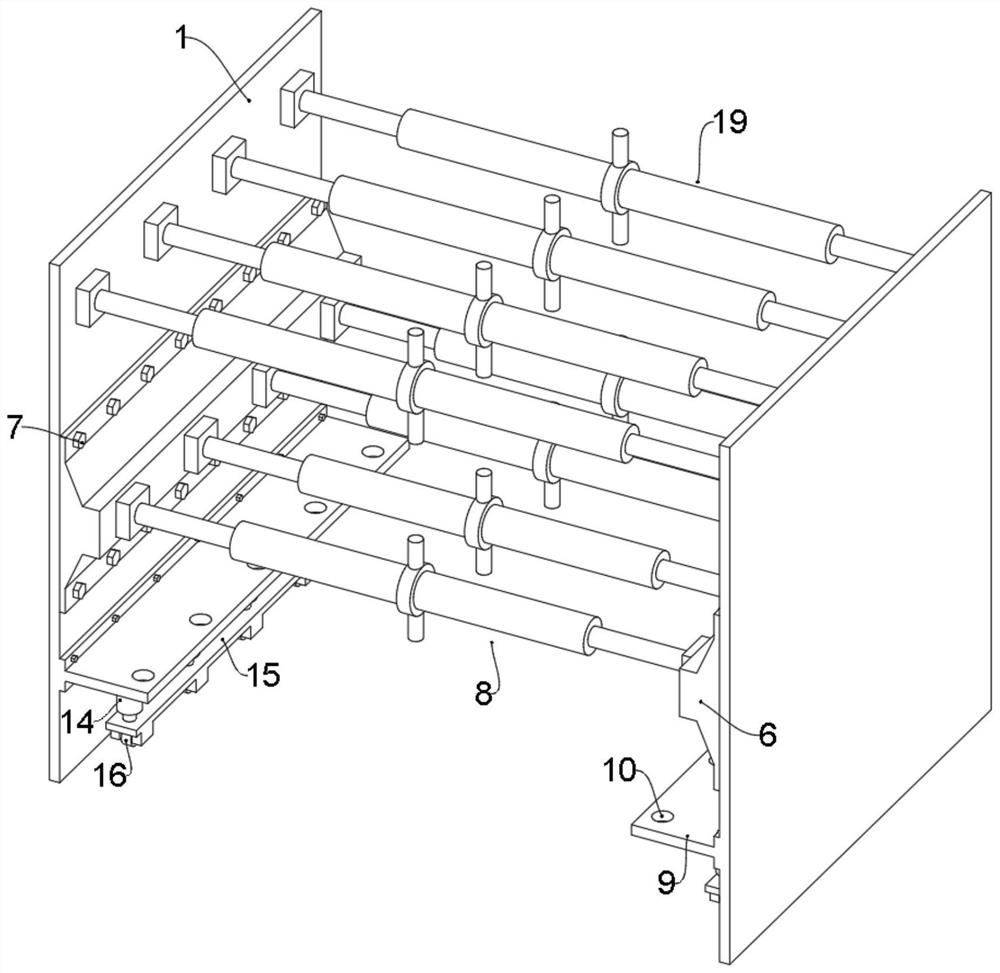

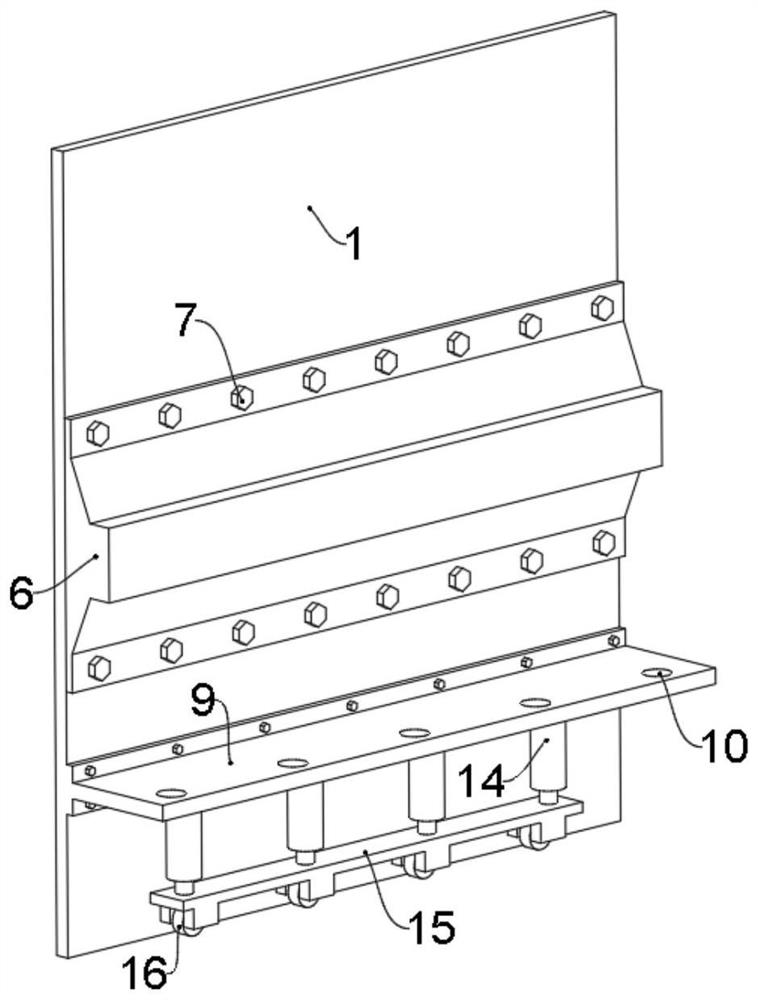

[0023] like Figure 1-5 As shown, a tie-rod-less construction formwork for a cover plate culvert body includes an inner formwork 1 and an outer formwork 2, the inner formwork 1 and the outer formwork 2 are arranged vertically and parallel to each other, and the side of the outer formwork 2 away from each other is provided with a The outer support frame 3, the lower side of the outer formwork 2 is provided with a gravel layer 4, mark the line at the position to be constructed, and excavate a rectangular foundation pit with a depth of 30-40 cm, and use the sand to lay it in the foundation pit to form sand gravel Layer 4, the lower side of the inner formwork 1 is provided with a base layer 5, and concrete is poured through the formwork in the middle of the upper end of the gravel layer 4, and the base layer 5 is formed after the concrete is dried. , the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com