Method for treating contaminants using three-way catalyst when starting internal combustion engine

A technology for internal combustion engines and pollutants, which is applied to engine components, internal combustion piston engines, exhaust gas treatment, etc. It can solve the problems of low hydrocarbon processing capacity, inability to provide pollution reduction, and does not provide for adjusting the amount of oxygen in the catalytic converter, so as to achieve pollution The effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

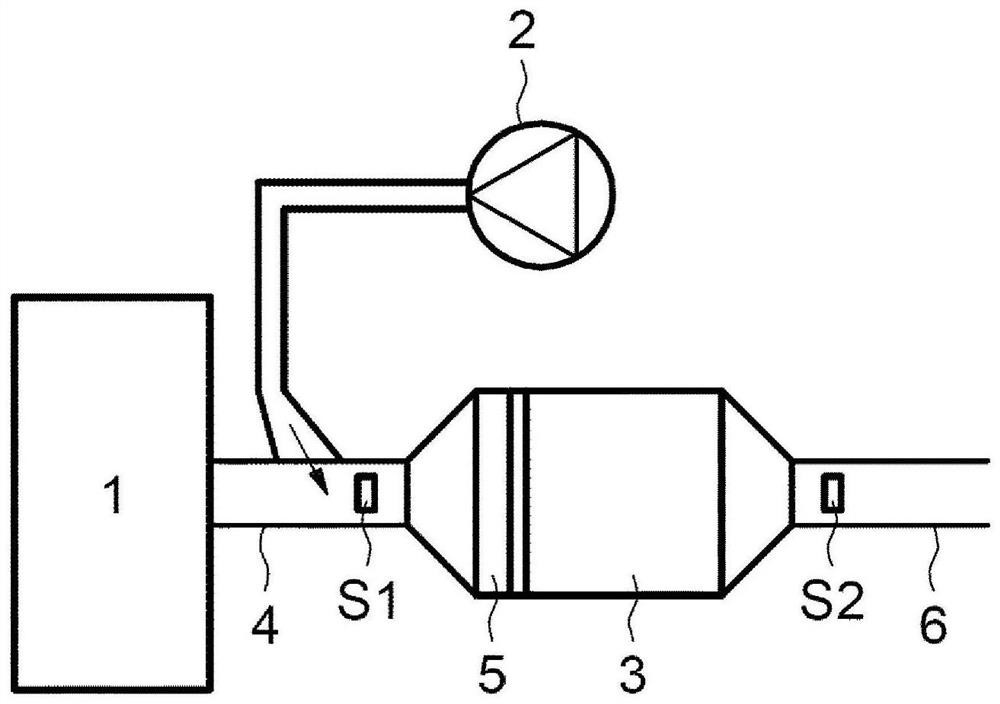

[0023] see figure 1 , which shows an embodiment of a system for the treatment of pollutants emitted by a vehicle having an internal combustion engine 1 with a catalytic device 3 arranged after the exhaust gas 4 discharged from the engine 1 .

[0024] The catalytic converter 3 comprises a three-way catalytic converter 3 provided with a so-called "precious" metal, such as palladium, platinum or rhodium. The three-way catalytic converter 3 is intended to treat the exhaust gas leaving the exhaust pipe 6 with three parallel chemical reactions of oxidation of carbon monoxide, oxidation of hydrocarbons and reduction of nitrogen oxides.

[0025] Multiple catalysts can be provided in series.

[0026] The catalyst 3 comprises an impregnated surface (referred to as a "washcoat") containing compounds based on ceria, which are capable of storing or releasing oxygen very quickly to facilitate catalytic reactions.

[0027] Catalyst 3 is only effective above about four hundred degrees Celsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com