Flotation method for efficiently purifying phosphogypsum

A phosphogypsum, high-efficiency technology, applied in the field of phosphogypsum treatment, can solve the problems of low dihydrate gypsum content and unfavorable reuse of building gypsum, and achieve the effects of easy equipment cost, low equipment corrosion, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

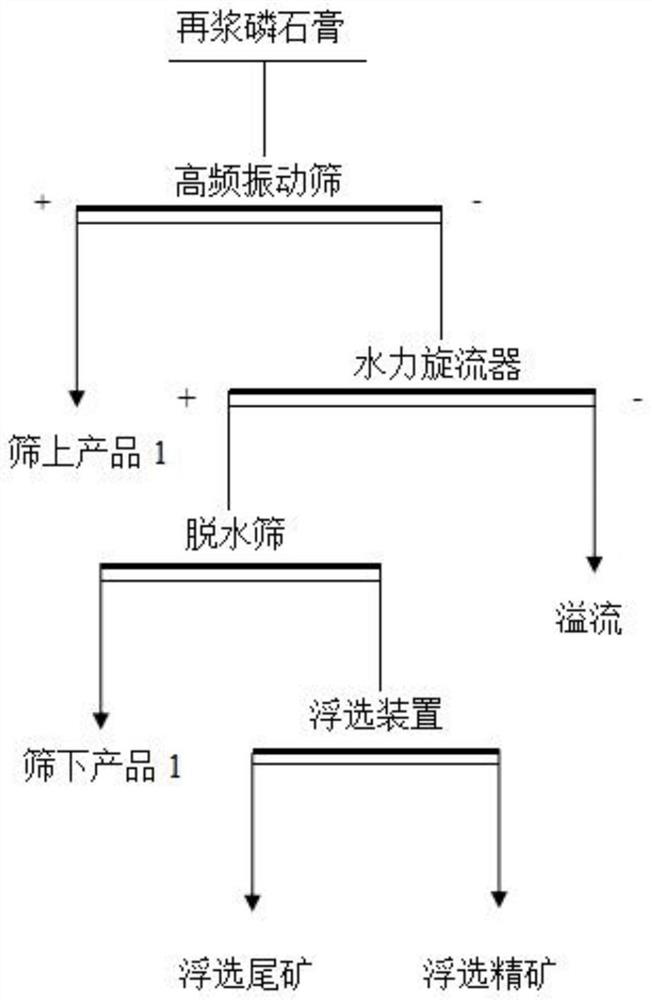

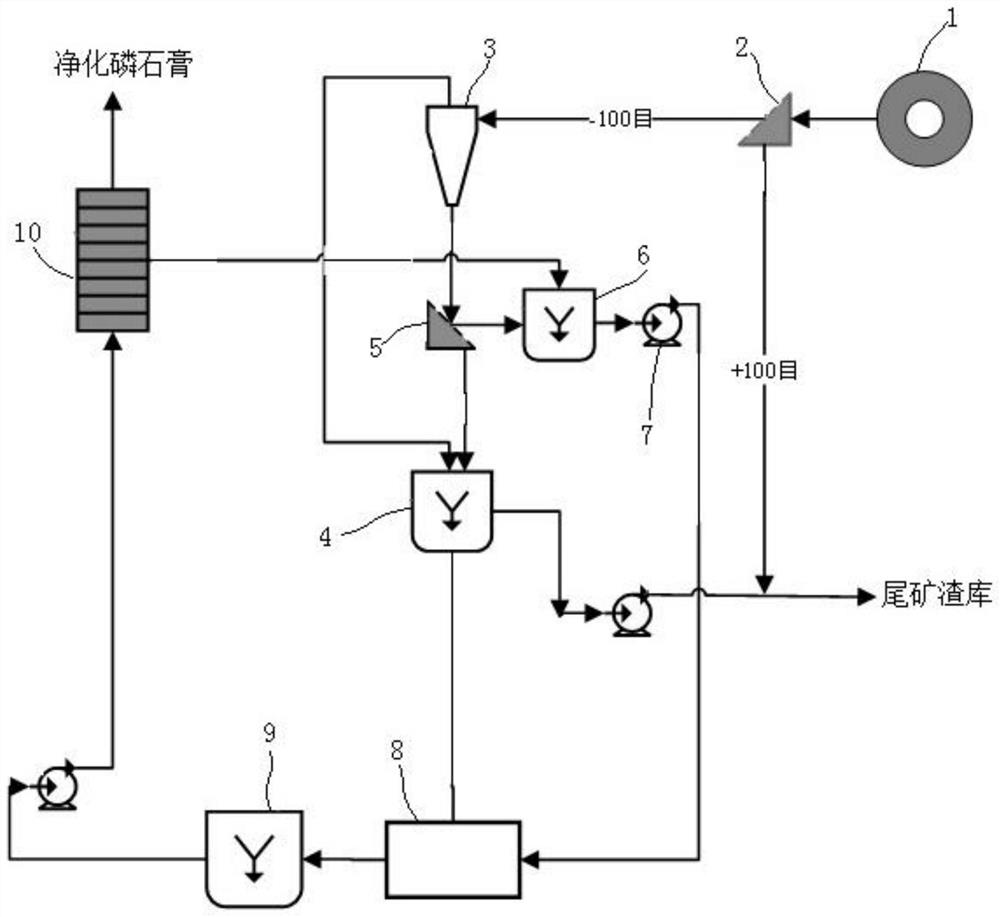

[0024] figure 1 A flotation method for efficiently purifying phosphogypsum is shown, comprising the steps of:

[0025] S1. The phosphogypsum from the wet-process phosphoric acid production transfer table filter 1 is pumped into the pump tank for slurry making, and the slurry concentration is 25% to 35%;

[0026] S2. Pump the slurry into the high-frequency vibrating screen 2 for screening, the +100-mesh coarse-grained product on the screen enters the tailings slag silo, and the -100-mesh product under the sieve is pumped into the hydrocyclone 3 for classification;

[0027] S3. The overflow product in the hydrocyclone 3 enters the tailings collection tank 4, and the sand settling product in the hydrocyclone 3 enters the dewatering screen 5;

[0028] S4. The product under the dewatering screen 5 enters the tailings collection tank 4, the product on the dewatering screen 5 enters the mineralization tank 6, and the pressure filter return water is added to adjust the slurry to a co...

Embodiment 2

[0032] The phosphogypsum produced by the wet-process phosphoric acid plant of a chemical fertilizer plant was transported from the rotary filter 1 to the reslurry tank, and diluted water was added, and the phosphogypsum slurry with a concentration of 30.7% was obtained during continuous stirring. Pump the slurry into the high-frequency vibrating screen 2 for screening, and the +100 mesh coarse-grained products on the screen enter the tailings slag storage.

[0033] The -100-mesh product under the sieve is driven into the hydrocyclone 3 through the slurry pump, and the working pressure is 0.10MPa, the concentration of the overflow product is 13.71%, the concentration of the settled sand product is 56.88%, and the overflow product flows to the tailings collection tank 4 by itself , the sand products flow to the dewatering screen 5 through the pipeline, and the mesh number of the screen is 40 meshes.

[0034] The phosphogypsum slurry is further removed from impurities such as wat...

Embodiment 3

[0038] The phosphogypsum produced by the wet-process phosphoric acid plant of a chemical fertilizer plant was transported from the rotary table filter 1 to the reslurry tank, and diluted water was added, and the phosphogypsum slurry with a concentration of 32.03% was obtained during continuous stirring. Pump the slurry into the high-frequency vibrating screen 2 for screening, and the +100 mesh coarse-grained products on the screen enter the tailings slag storage.

[0039] The -100-mesh product under the sieve is driven into the hydrocyclone 3 by the slurry pump, and the working pressure is 0.11MPa, the concentration of the overflow product is 15.16%, and the concentration of the settled sand product is 57.34%. The overflow product flows to the tailings collection tank 4 by itself , the sand product flows to the dewatering screen 5 through the pipeline, and the mesh number of the screen is 60 meshes.

[0040] The phosphogypsum slurry is further removed from impurities such as w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com