Integrated negative pressure sterilization and deodorization garbage treatment device

A garbage treatment device, an integrated technology, applied in the field of integrated negative pressure sterilization and deodorization garbage treatment equipment, can solve the problems of high saturation cost, residual ozone pollution, high concentration of bacteria, etc., to solve the problem of odor, deodorization The effect of high sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings:

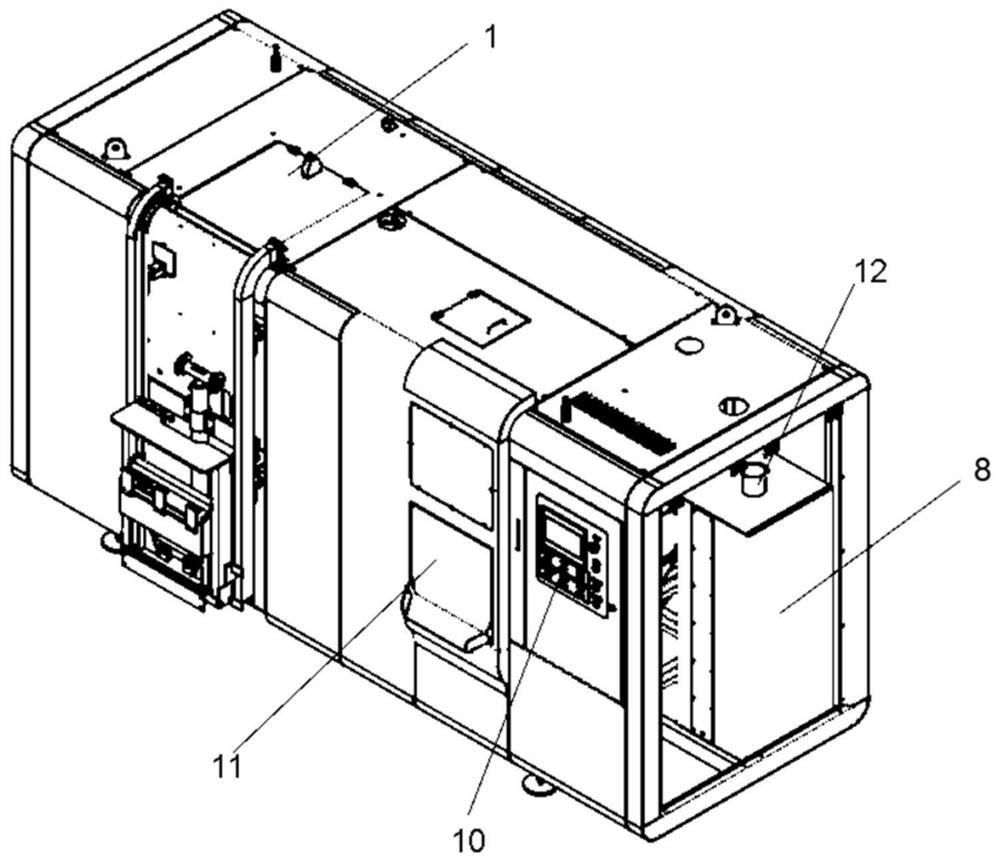

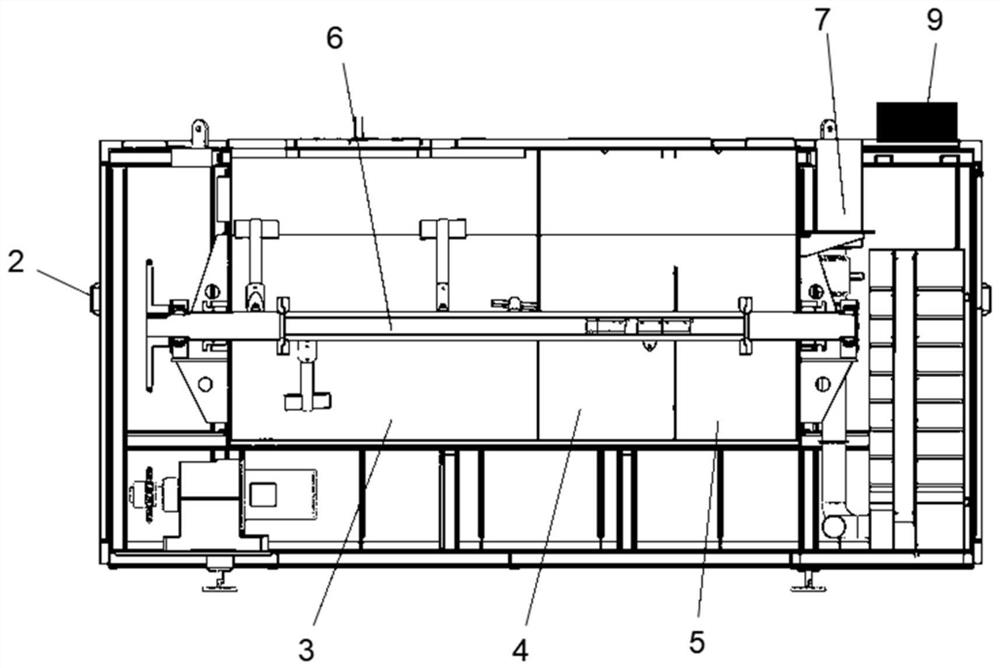

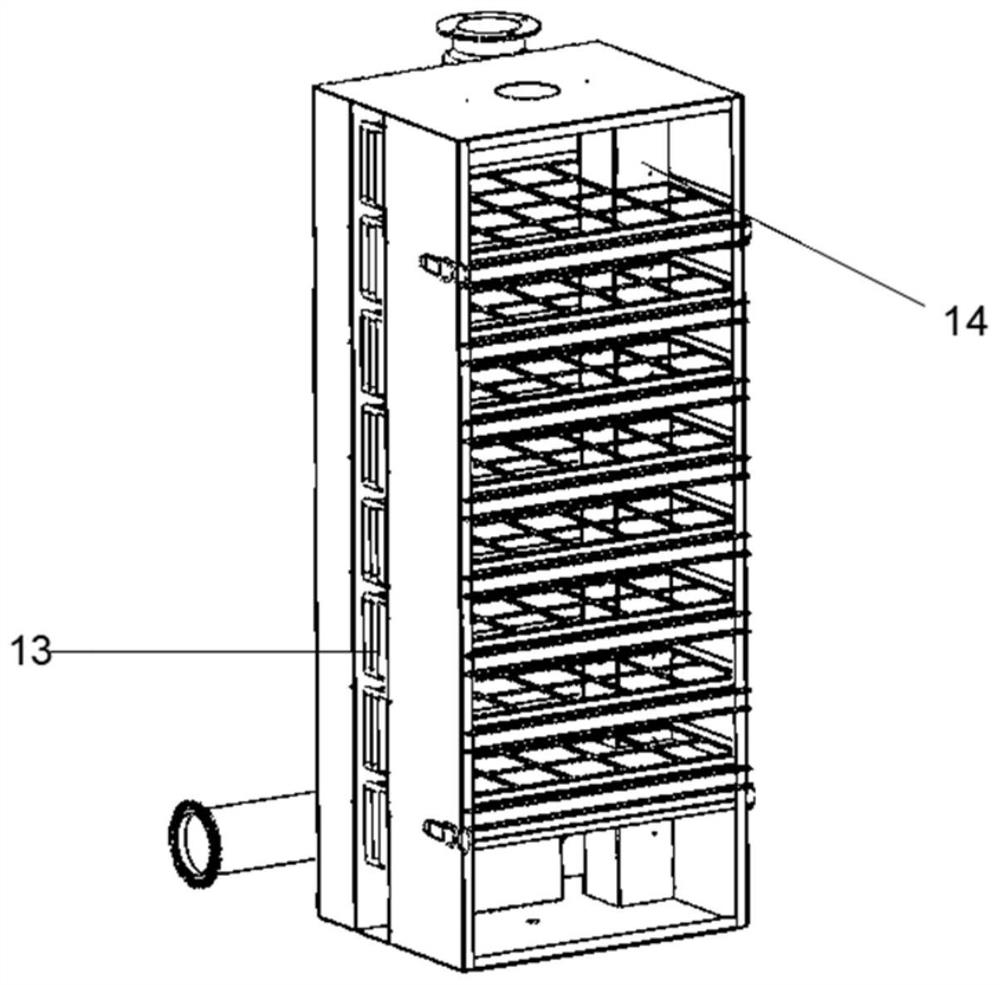

[0023] like figure 1 figure 2 image 3 As shown in the figure, an integrated negative pressure sterilization and deodorization garbage disposal device includes: a feed port 1, a butterfly valve air inlet 2, an anaerobic tank 3, a facultative aerobic tank 4, an aerobic tank 5, a stirring device 6, a pressure transmitter 7, deodorizing device 8, fan system 9, PLC control system 10, material outlet 11, air outlet 12, ozone generator 13, catalyst honeycomb 14.

[0024] The working process of the whole device is as follows:

[0025] The gas that the whole set of garbage disposal equipment produces passes through the anaerobic tank 3, the facultative oxygen tank 4 and the aerobic tank 5, then the pressure transmitter 7, and finally enters the deodorization device 8. The PLC control system 10 is used to control the air volume of the whole system. An ozone generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com