Large-size difficult-to-deform nickel-based superalloy cast ingot and preparation method thereof

A nickel-based superalloy and superalloy technology, applied in the field of superalloys, can solve the problems of high cost, easy cracking, complex process, etc., and achieve the effects of stable mass production, reducing cracking tendency, and eliminating dendrite segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the large-scale hard-to-deform nickel-based superalloy ingot provided in this application includes the following steps:

[0057] Triple smelting: The superalloy raw materials are smelted through the triple process of vacuum induction melting, protective atmosphere electroslag remelting and vacuum consumable remelting to obtain consumable ingots. The raw materials of superalloys can be selected from electrolytic nickel, metal chromium, cobalt plates, and molybdenum bars , electrolytic aluminum block, titanium sponge, high-purity carbon, nickel-magnesium, nickel-niobium, etc.;

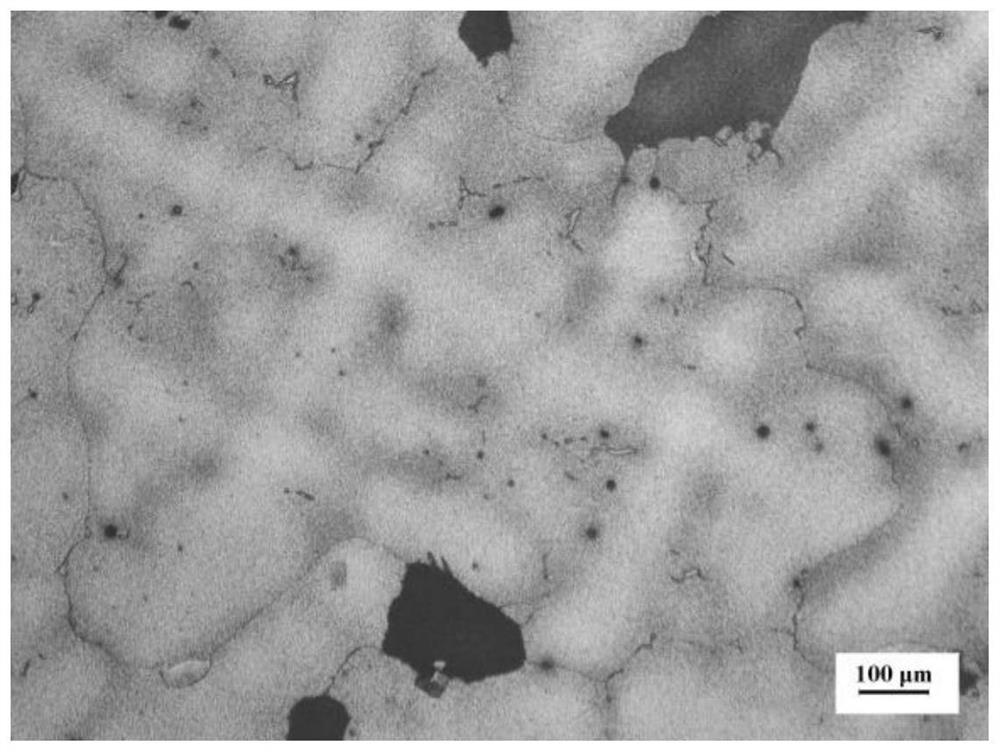

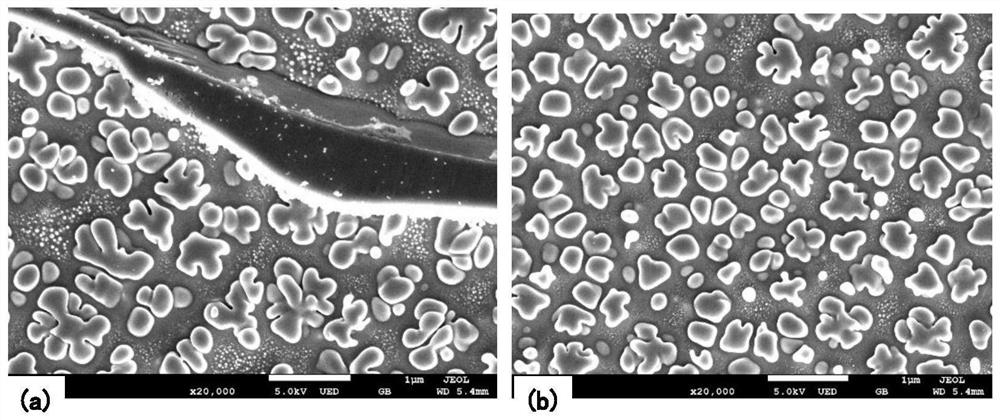

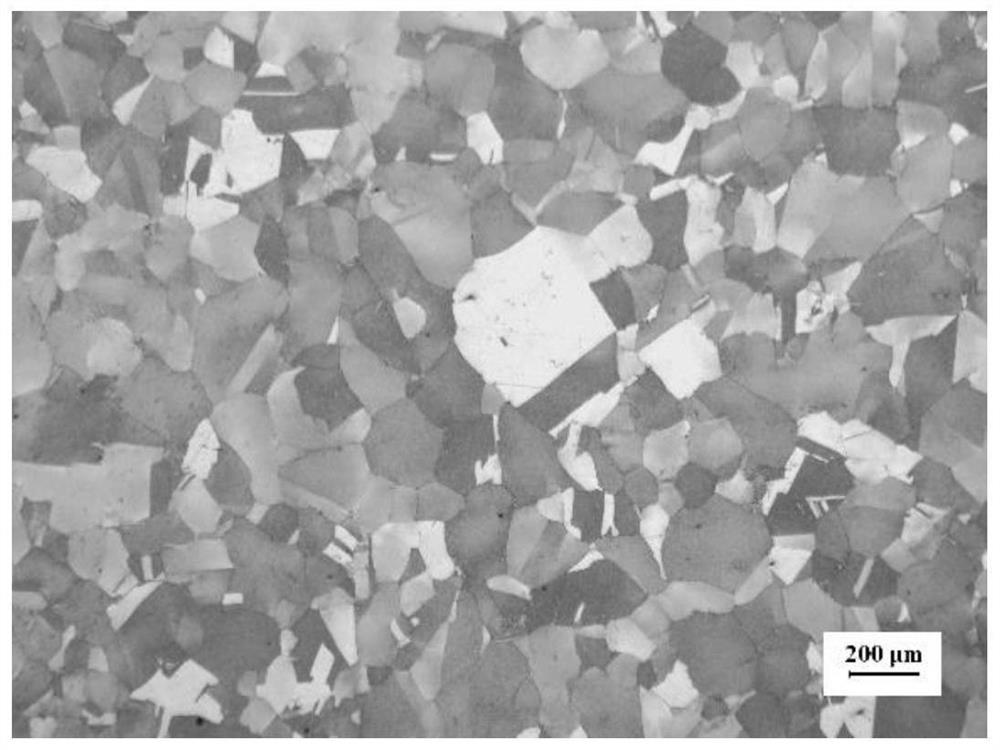

[0058] Homogenization treatment: multi-stage homogenization treatment is adopted, the temperature of the consumable ingot is raised to (830-970) ℃ within (2-4) hours, and kept at (830-970) ℃ for (2-4) hours; then ( Raise the temperature to (1115-1125) ℃ at a heating rate of 45-60) ℃ / h, and keep warm for 10-14h; raise the temperature to (1130-1140) ℃ at a heating rate of (...

Embodiment 1

[0063] A method for preparing a large-scale hard-to-deform nickel-based superalloy ingot, comprising the following steps:

[0064] Triple smelting: The raw materials of GH4742 high-temperature and difficult-to-deform nickel-based superalloy are sequentially passed through S1: vacuum induction melting, S2: protective atmosphere electroslag remelting and S3: vacuum consumable remelting to obtain consumable ingots, and vacuum induction melting (VIM ) alloy ingot diameter is 410mm, alloy ingot diameter for protective atmosphere electroslag remelting (P-ESR) is 580mm, and alloy ingot diameter for vacuum consumable remelting (VAR) is 660mm; among them, S1: vacuum induction melting (VIM) operation specifically includes the following steps:

[0065] S1-1. According to the composition requirements of the GH4742 alloy, weigh the raw materials. The weight percentage (wt%) of each raw material is: C: 0.04; Co: 10.0; Cr: 13.0; Mo: 4.5; Ti: 2.50; Al: 2.5; Nb : 2.7; the balance is Ni, put t...

Embodiment 2

[0080] A method for preparing a large-scale hard-to-deform nickel-based superalloy ingot, comprising the following steps:

[0081] Triple smelting: The raw materials of GH4742 high-temperature and difficult-to-deform nickel-based superalloy are sequentially passed through S1: vacuum induction melting, S2: protective atmosphere electroslag remelting and S3: vacuum consumable remelting to obtain consumable ingots, and vacuum induction melting (VIM ) alloy ingot diameter is 390mm, alloy ingot diameter for protective atmosphere electroslag remelting (P-ESR) is 600mm, and alloy ingot diameter for vacuum consumable remelting (VAR) is 660mm; among them, S1: vacuum induction melting (VIM) operation specifically includes the following steps:

[0082] S1-1. According to the composition requirements of the GH4742 alloy, weigh the raw materials. The weight percentage (wt%) of each raw material is: C: 0.05; Co: 10.5; Cr: 13.5; Mo: 5.5; Ti: 2.60; Al: 2.55; Nb : 2.7; the balance is Ni, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com