A kind of high nb content ti-nb alloy ingot billet forging method

An alloy ingot and billet forging technology is applied in the field of titanium alloy forging, which can solve the problems of easy generation of segregation forging deformation resistance, difficulty in forming homogeneous bars, high-density inclusions, etc., so as to improve production efficiency and bar yield. , Increase the high temperature plasticity, the effect of small fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

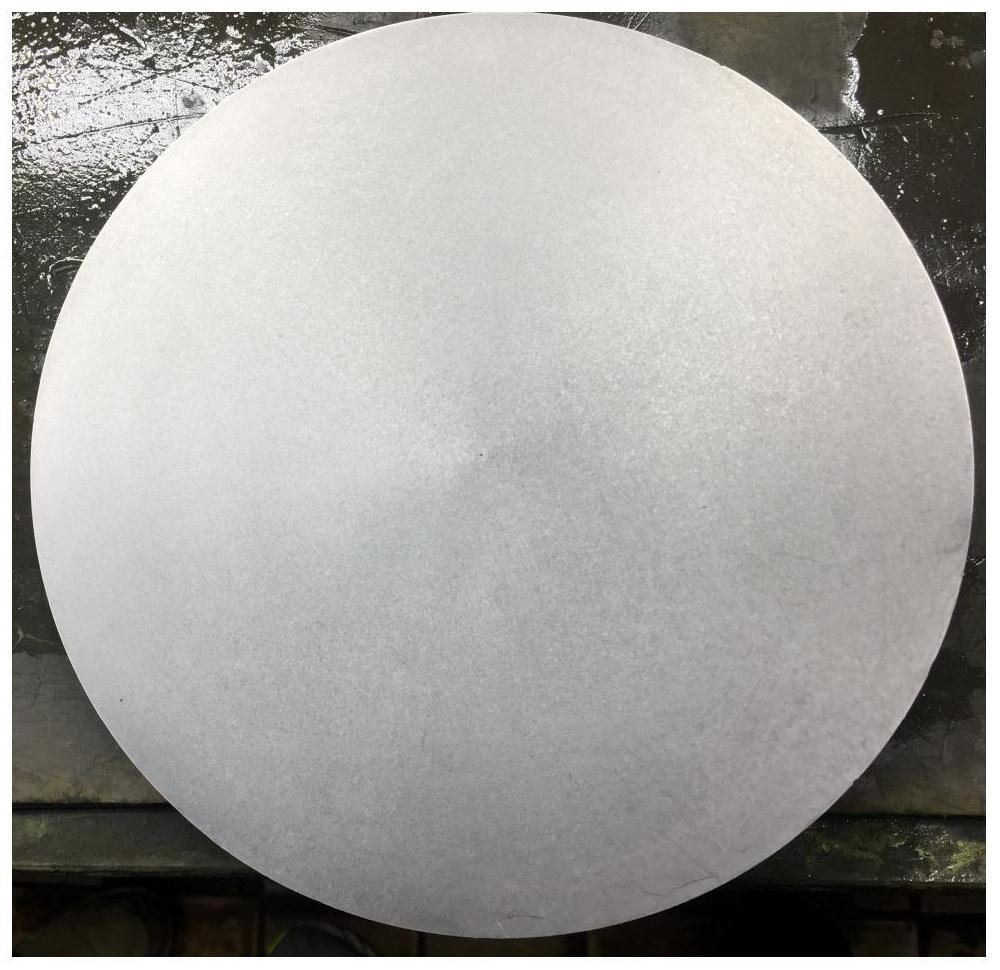

Image

Examples

Embodiment 1

[0023] A high Nb content Ti-Nb alloy ingot blank forging method, comprising the following steps:

[0024] Step 1): cutting off the riser and head shrinkage cavity and shrinkage porosity of the Ti-Nb alloy ingot smelted by vacuum self-consumption, machining to remove surface defects, and then performing homogenization heat treatment to form the first annealed ingot;

[0025] Wherein, during the homogenization heat treatment, the heat treatment temperature range is 1200-1300°C, and the holding time range is 24-72h.

[0026] Step 2): Upsetting the first annealed ingot described in step 1), reducing the aspect ratio of the rod, so that the aspect ratio of the first forged billet ranges from 1.5-3 to form the first forged billet.

[0027] Step 3): Forging the first forging blank obtained in step 2) for n times to form a second forging blank;

[0028] The n fire times are 4-6 fire times, and the heating temperature of each fire time is 1200±50°C, 1160±50°C, 1100±50°C and 1050±50°C,...

Embodiment 2

[0035] In this embodiment, the Ti-45Nb alloy ingot smelted by vacuum consumable arc with a size of φ460×2500mm is subjected to billet forging, and the forging equipment is 10000t fast forging machine.

[0036] Step 1): Homogenizing annealing: After polishing the surface of the Ti-45Nb alloy ingot, perform homogenizing annealing at a heating temperature of 1200°C / 48h to form a first annealed ingot.

[0037] Step 2): performing upsetting deformation on the first annealed ingot in step 1), reducing the aspect ratio of the rod, and forming the first forging billet;

[0038] Step 3): The first forging blank obtained in step 2) is forged six times to form a second forging blank. in:

[0039] First fire: heating system 1200℃ / 10h, upsetting φ460×2500mm to the height direction H=2100mm, turning over and continuing upsetting and shaping to φ620×1400mm;

[0040] The second fire: heating system 1200℃ / 12h, upsetting φ620×1400mm to the height direction H=1000mm, turning over to continue u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com