A kind of manganese additive for aluminum alloy and preparation method thereof

A manganese additive and aluminum alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unfavorable quality control of aluminum alloy, complex production process, serious aluminum burning loss, etc., achieve fast melting speed and reduce dendrite segregation , The effect of less burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

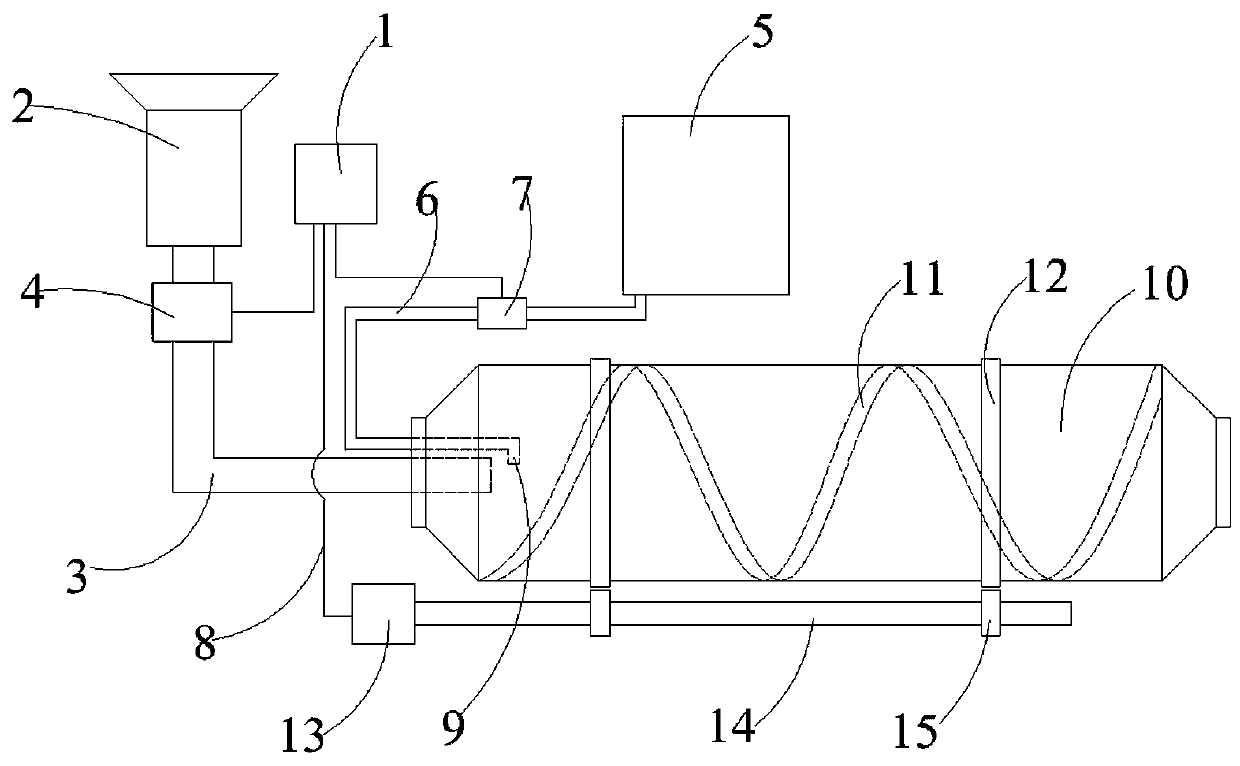

Method used

Image

Examples

Embodiment 1

[0041] (a) Crushing of raw materials: 75kg of manganese powder, 4kg of aluminum powder, 0.03kg of magnesium powder, 0.3kg of iron powder and 0.3kg of silicon powder are crushed under nitrogen protection to a particle size of 40-325 mesh; in terms of mass fraction, 40-50 Mesh accounts for 37.7%, 50~80 mesh accounts for 33%, 80~150 mesh accounts for 25%, 150~325 mesh accounts for 4.3%;

[0042] (b) Compounding: Add 0.1 kg of zinc stearate as a release agent and 0.2 kg of modified starch as a binder to the crushed raw materials in step (a), and add water to stir in a horizontal powder stirring device 20 minutes; the amount of water added is 1% of the total mass of raw materials, that is, 0.8kg;

[0043] (c) Compression: Press the mixture compounded in step (b) into a round cake under 20MPa;

[0044] (d) Drying: Dry the round cake obtained in step (c) in a desiccator under the protection of nitrogen at a temperature of 200°C for 50 minutes to obtain a finished product.

Embodiment 2

[0046] (a) Crushing of raw materials: 95kg of manganese powder, 23kg of aluminum powder, 0.03kg of magnesium powder, 0.3kg of iron powder and 0.3kg of silicon powder are crushed under the protection of nitrogen to a particle size of 40-325 mesh; in terms of mass fraction, 40-50 Mesh accounts for 37.7%, 50~80 mesh accounts for 33%, 80~150 mesh accounts for 25%, 150~325 mesh accounts for 4.3%;

[0047] (b) Compounding: Add 0.2 kg of zinc stearate as a release agent and 0.4 kg of modified starch as a binder to the crushed raw materials in step (a), and stir in a horizontal powder stirring device for 30 minutes; the amount of water added is 3% of the total mass of raw materials, that is, 3.6kg;

[0048] (c) Compression: Press the mixture compounded in step (b) into a round cake at 30MPa;

[0049] (d) Drying: Dry the round cake obtained in step (c) in a desiccator under the protection of nitrogen at a temperature of 280°C for 70 minutes to obtain a finished product.

Embodiment 3

[0051] (a) Crushing of raw materials: 80kg of manganese powder, 10kg of aluminum powder, 0.03kg of magnesium powder, 0.3kg of iron powder and 0.3kg of silicon powder are crushed under the protection of nitrogen to a particle size of 40~325 mesh; in terms of mass fraction, 40~50 Mesh accounts for 37.7%, 50~80 mesh accounts for 33%, 80~150 mesh accounts for 25%, 150~325 mesh accounts for 4.3%;

[0052](b) Compounding: Add 0.14 kg of zinc stearate as a release agent and 0.25 kg of modified starch as a binder to the crushed raw materials in step (a), and stir in a horizontal powder stirring device for 25 minutes; the amount of water added is 2% of the total mass of raw materials, that is, 1.8kg;

[0053] (c) Compression: compress the mixture compounded in step (b) into granules under 22MPa;

[0054] (d) Drying: Dry the granules obtained in step (c) in a drier under the protection of nitrogen at a temperature of 220°C for 55 minutes to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com