High-plasticity phase separation Zr-based amorphous alloy and preparation method and application thereof

An amorphous alloy and phase separation technology, applied in the field of bulk amorphous alloys, can solve the problems of limiting the engineering promotion and application of amorphous alloys, the failure to reflect the mechanical properties of fracture toughness, and the decrease of shear bands, etc., to achieve convenient preparation , Improve plasticity at room temperature, cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation and properties of Zr-Cu-Ni-Al bulk amorphous alloy

[0050] Design Zr 60 Cu a Ni b Al 5 Amorphous alloy composition, where a = 5, 10, 15, 20, 25, 30; b = 35-a. The resulting composition is Zr 60 Cu 5 Ni 30 Al 5 , Zr 60 Cu 10 Ni 25 Al 5 , Zr 60 Cu 15 Ni 20 Al 5 , Zr 60 Cu 20 Ni 15 Al 5 , Zr 60 Cu 25 Ni 10 Al 5 and Zr 60 Cu 30 Ni 5 Al 5 alloy.

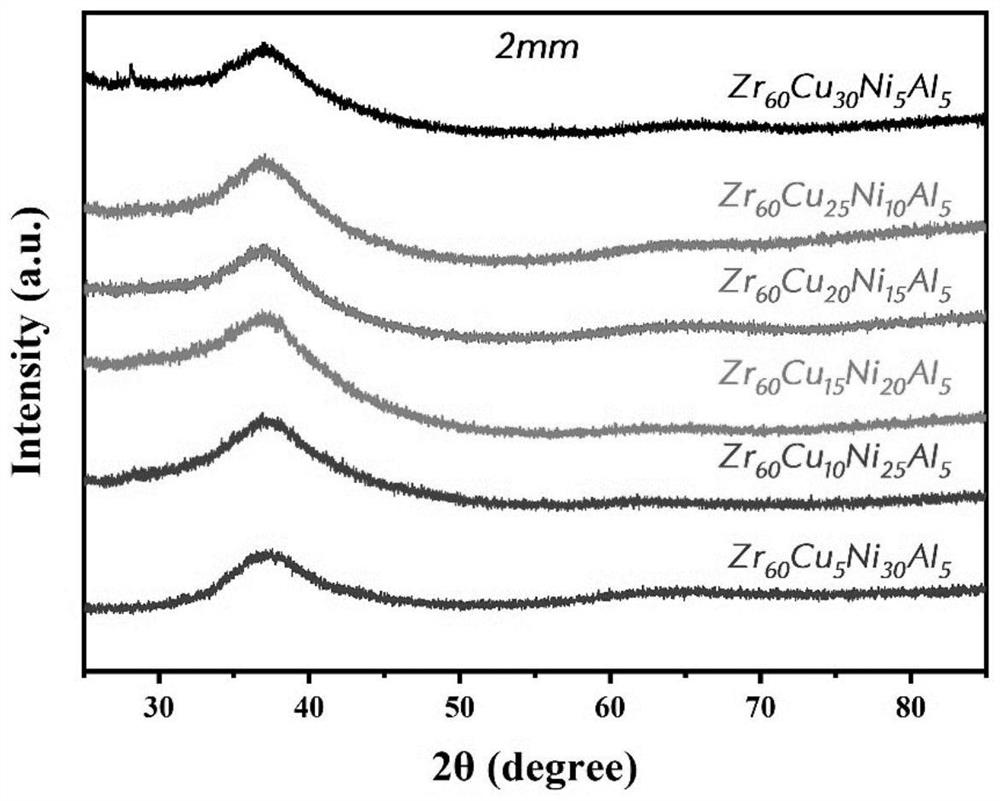

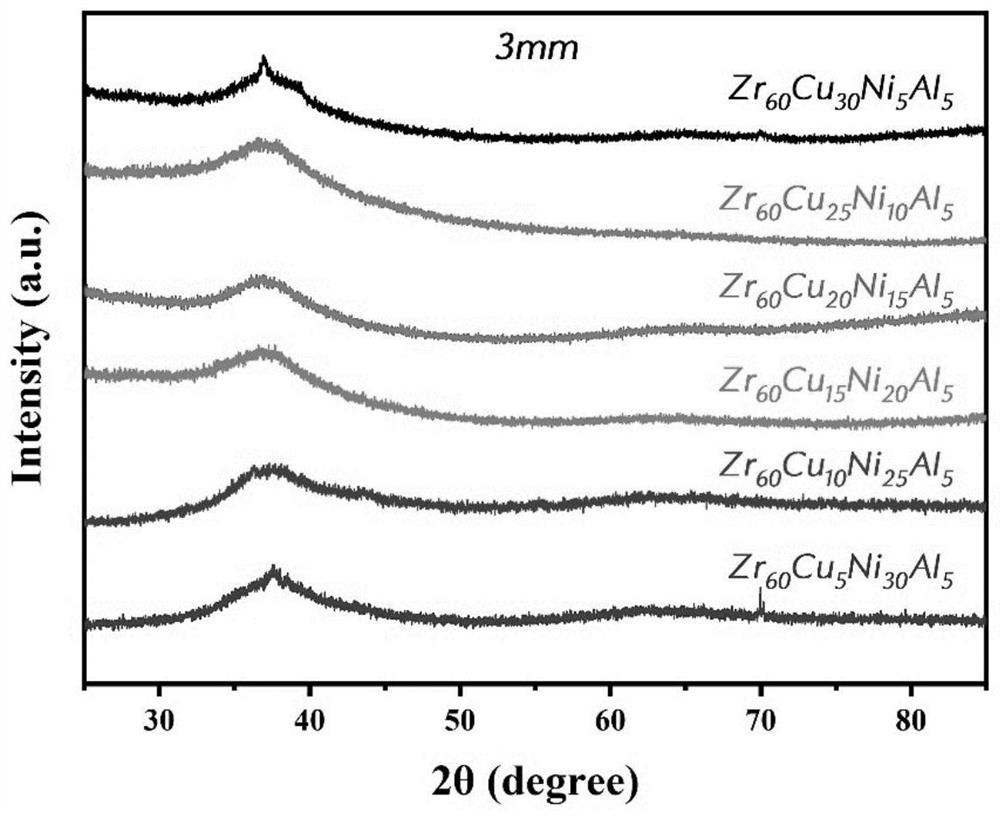

[0051] like figure 1 and figure 2 shown as Zr 60 Cu 5 Ni 30 Al 5 , Zr 60 Cu 10 Ni 25 Al 5 , Zr 60 Cu 15 Ni 20 Al 5 , Zr 60 Cu 20 Ni 15 Al 5 , Zr 60 Cu 25 Ni 10 Al 5 and Zr 60 Cu 30 Ni 5 Al 5 The X-ray diffraction (XRD) patterns of 2mm and 3mm alloy samples show that all components can form a single amorphous sample with a diameter of 2mm, and most components can form a single amorphous sample with a diameter of 3mm.

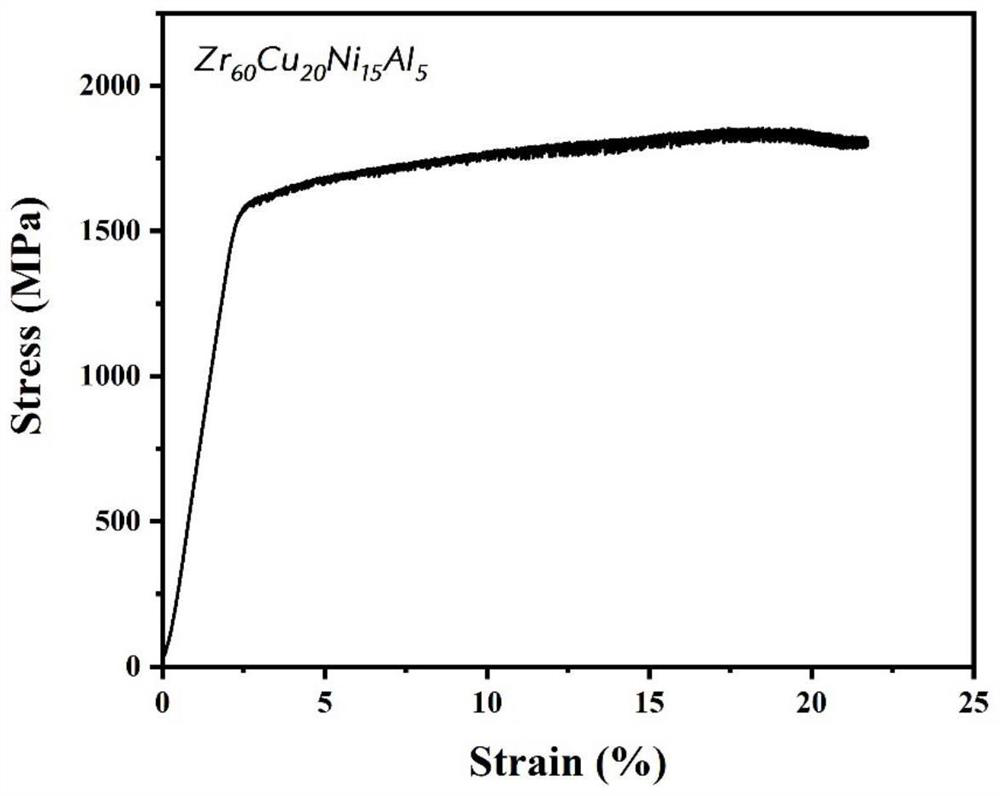

[0052] Zr 60 Cu 20 Ni 15 Al 5 The compressive stress-strain curve of the alloy 2mm specimen is shown in 3. It can be seen that the al...

Embodiment 2

[0054] Example 2: Preparation and properties of Zr-Cu-Fe-Al bulk amorphous alloy

[0055] Design Zr 60 Cu 20 Fe 15 Al 5 Amorphous alloy composition. like Image 6 The X-ray diffraction (XRD) pattern of its 2 mm sample is shown, and the pattern indicates that the composition can form a single amorphous sample of 2 mm diameter. The compressive stress-strain curve of the alloy 2mm sample is shown in 7, and it can be seen that its plastic deformation capacity can reach 10%.

Embodiment 3

[0056] Example 3: Preparation and properties of Zr-Cu-Ni-Fe-Al bulk amorphous alloy

[0057] Design Zr 60 Cu 20 Ni 14 Fe 1 Al 5 Amorphous alloy composition. like Figure 8 The X-ray diffraction (XRD) pattern of its 2 mm sample is shown, and the pattern indicates that the composition can form a single amorphous sample of 2 mm diameter. The compressive stress-strain curve of the alloy 2mm sample is shown in 9, and it can be seen that its plastic deformation capacity can reach 10%.

[0058] Design Zr 60 Cu 20 Ni 10 Fe 5 Al 5 Amorphous alloy composition. like Figure 10 Shown is the X-ray diffraction (XRD) pattern of its 3 mm sample, which indicates that the composition can form a single amorphous sample of 3 mm diameter. The compressive stress-strain curve of the alloy 2mm specimen is shown in 11, and it can be seen that its plastic deformation capacity can reach 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com