Seed crystal layer impurity removal method for DRAM (Dynamic Random Access Memory) evaporation process

A technology of seed crystal layer and impurities, applied in vacuum evaporation plating, metal material coating process, coating and other directions, can solve the problems of poor evaporation effect and ineffective removal, and achieve good evaporation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

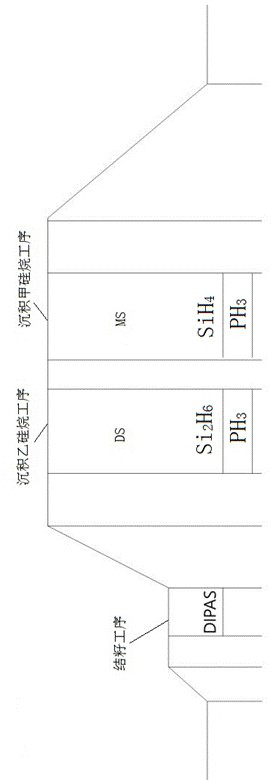

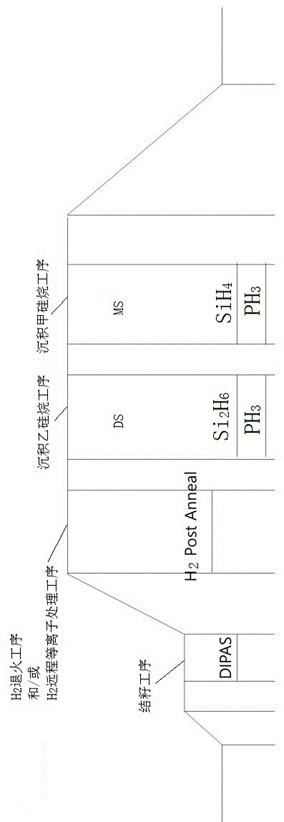

[0023] like figure 1 , figure 2 As shown, a method for removing impurities in a seed crystal layer used in a DRAM evaporation process, after the seed crystal layer is evaporated, the H 2 Annealing process and / or H 2 Remote plasma treatment process.

[0024] This facilitates the effective removal of impurities such as carbon and nitrogen generated during the seed setting process, resulting in a better evaporation effect.

[0025] As a preferred technical solution, it includes a seed setting process, a process of depositing disilane, and a process of depositing monosilane, which are arranged in chronological order. 2 Annealing process and / or H 2 The remote plasma treatment process is provided between the seeding process and the deposition of disilane.

[0026] This facilitates the timely removal of carbon, nitrogen and other impurities generated during the seed setting process after seed setting.

[0027] As a preferred technical solution, H 2 Annealing process and / or H ...

Embodiment 2

[0044] like figure 1 , figure 2 As shown, as a further optimization of Embodiment 1, this embodiment includes all the technical features of Embodiment 1. In addition, this embodiment also includes the following technical features:

[0045] In order to form a seed layer for evaporating a thin silicon film, it will contain chemicals deposited by DIPAS and SAM24, and contain impurities such as carbon and nitrogen. In order to remove impurities, after evaporating the seed layer, carbon and nitrogen impurities are introduced into H 2 Annealing process or H 2 Remote plasma treatment process removal.

[0046] When vapor deposition is performed during the reaction, H 2 Annealing, the carbon and nitrogen generated after DIPAS are forcibly removed, and the form of contact is filled in the subsequent deposition of DS and MS.

[0047] Preferably, H 2 Annealing after deposition of disilane and removal of SiH 4 can also be done later.

[0048] Preferably, impurities formed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com