Discharging device and method for condensate water of steam heat exchanger

A discharge device and condensed water technology, applied in steam/steam condensers, chemical instruments and methods, transportation and packaging, etc., can solve problems such as reduced service life of steam heat exchangers, cracks, and poor drainage of condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

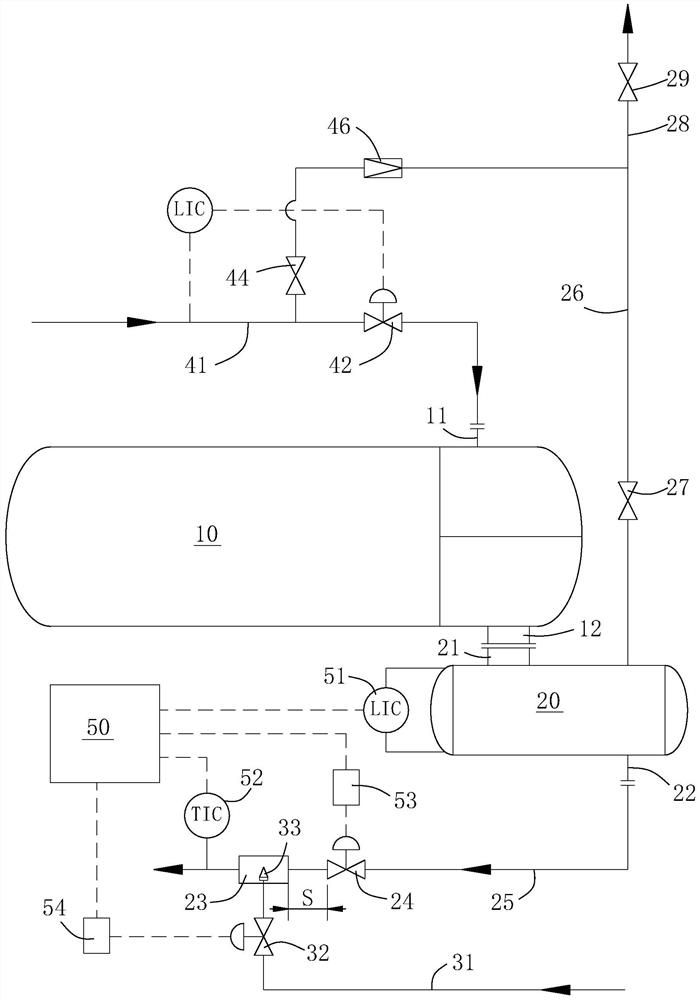

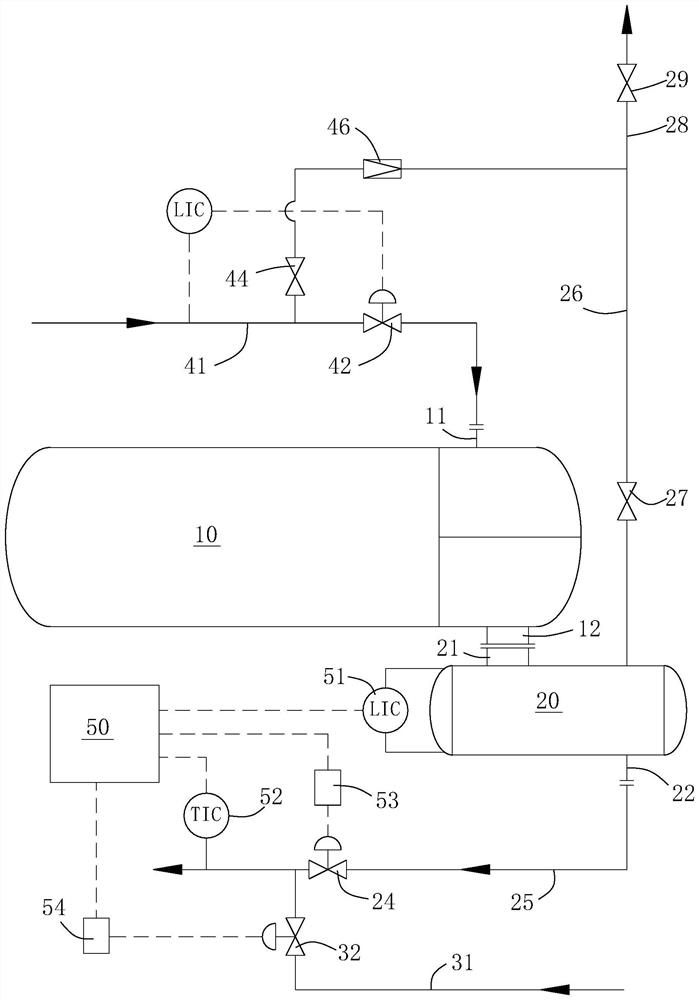

[0026] see figure 1 , a device for discharging condensed water of a steam heat exchanger, which comprises a condensed water tank 20 arranged below the steam heat exchanger 10, a condensed water discharge port 12 is arranged at the lower end of the steam heat exchanger 10, and the steam pipe 41 is connected to the On the steam inlet 11 at the top of the steam heat exchanger 10, a flow control valve 42 is installed on the steam pipe 41. In this embodiment, the steam heat exchanger 10 is used at the bottom of a distillation column or a fractionation column. Reboiler.

[0027] A water inlet 21 is provided on the top of the condensed water tank 20, the condensed water discharge port 12 is directly connected to the water inlet 21, the condensed water discharge port is located above the water inlet, and is not provided between the condensed water discharge port and the water inlet valve. It can be understood that, in another embodiment, when the installation space is limited, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com