Detachable cooler easy to maintain and capable of being cleaned inside

A detachable, cooler technology, applied in water shower coolers, direct contact heat exchangers, indirect heat exchangers, etc., can solve the problems of low cooling efficiency, inconvenient installation and disassembly, energy waste, etc., and achieve a convenient combination and disassembly, efficient heat dissipation, convenient maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

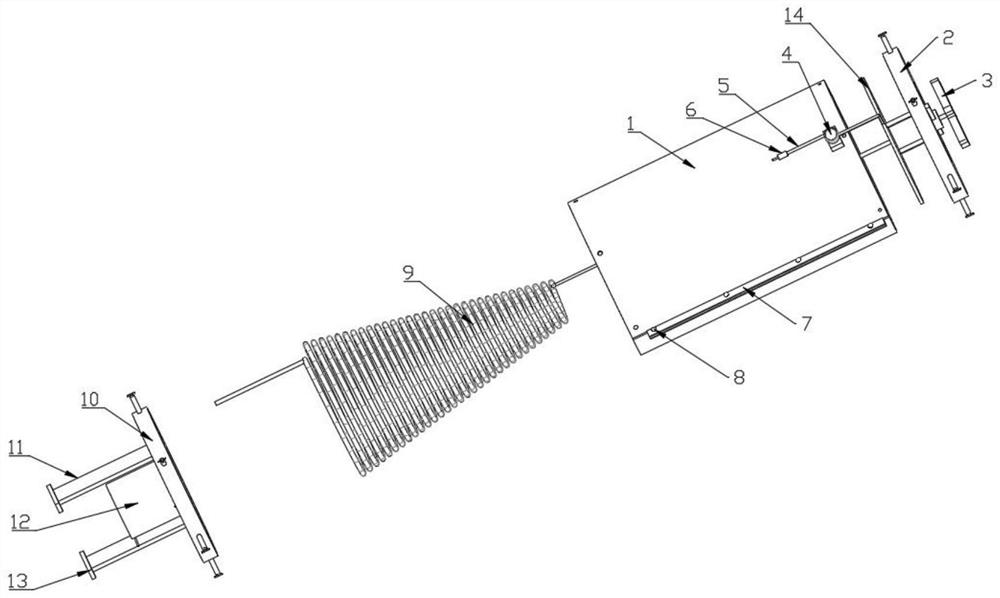

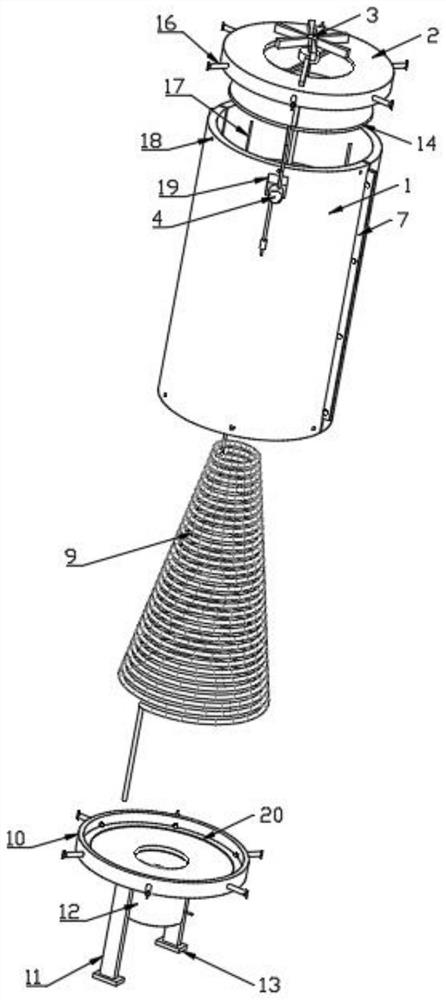

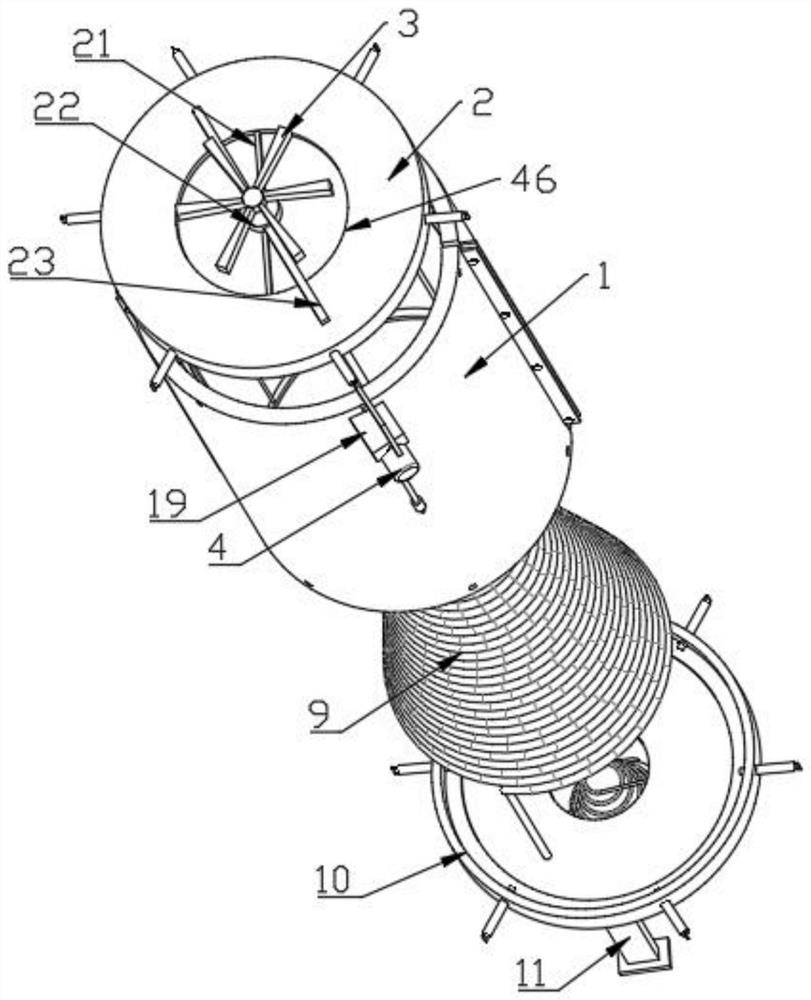

[0048] like Figure 1-Figure 13 As shown, the present embodiment provides a detachable cooler that is easy to maintain and can be cleaned inside, including two sets of shells 1 with a semi-annular structure, and the two sets of shells 1 are fixed by a strip-type fixing plate assembly. The outer bottom and top of the casing 1 are provided with card holes 18, and the outer top and bottom of the casing 1 are respectively sleeved with an upper cover 2 and a lower cover 10, and the outer sides of the upper cover 2 and the lower cover 10 The second hollow tube 25 and the first hollow tube 16 are arranged at equal angles to cooperate with the clamping hole 18;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com