Robot for recycling slurry at bottom of radioactive waste liquid storage tank

A radioactive waste liquid and robot technology, which is applied in radioactive purification, nuclear engineering, etc., can solve problems such as the inability to control the particle size of mud crushing, incomplete cleaning of sludge, and damage to diaphragm pumps, etc., to achieve convenient cleaning and decontamination and Effect of cleaning treatment, avoiding unsafe problems, and preventing particle deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

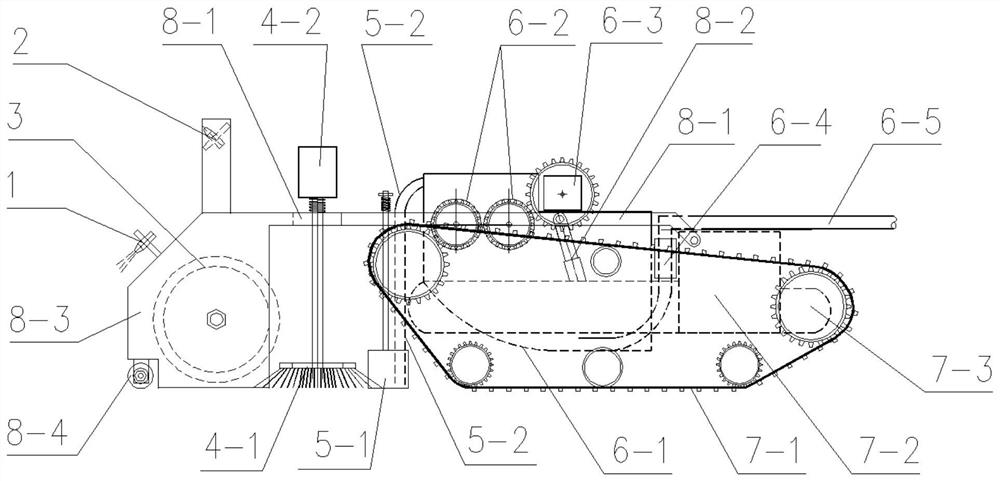

[0058] like figure 1 The shown robot for recovering mud from the bottom of a radioactive waste liquid storage tank includes a cutting nozzle 1, a cleaning nozzle 2, a spiral cutting drum 3, a cleaning rotary brush 4, a suction bucket 5, a liquid collection box 6, a double crawler trolley 7, Head support 8.

[0059] like Figures 2 to 4 As shown, the double-tracked trolley 7 is a moving platform of the robot, which is composed of a trolley support 7-2, a crawler 7-1 arranged outside the trolley support 7-2, and a power system 7-3. The power system 7-3 is driven by a hydraulic motor, which can realize the forward, backward and turning actions of the robot.

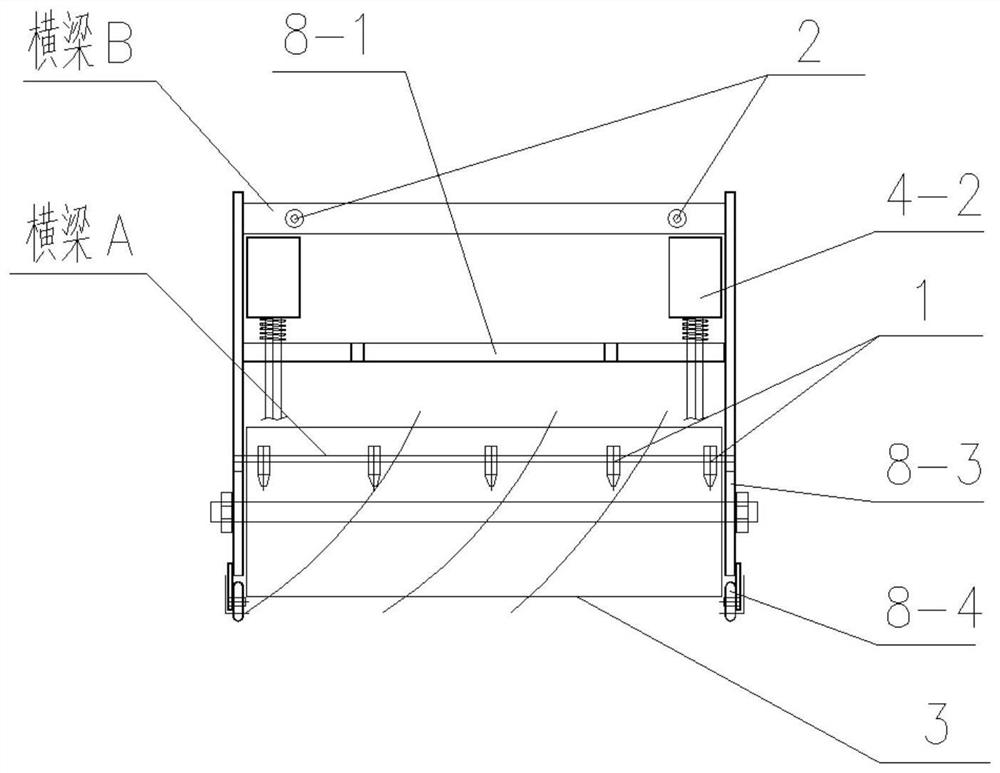

[0060] The head support 8 includes a lift arm 8-1, a hydraulic cylinder 8-2, a roller side baffle 8-3 and a roller 8-4. Two drum side baffles 8-3 are respectively provided on both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com