Flame-retardant and explosion-proof new energy automobile battery shell and preparation method thereof

A new energy vehicle, flame retardant and explosion-proof technology, applied in the direction of isolation of batteries and their environment, protective equipment, battery pack components, etc., can solve problems such as safety accidents and explosions, and achieve the effect of improving production efficiency and reducing processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

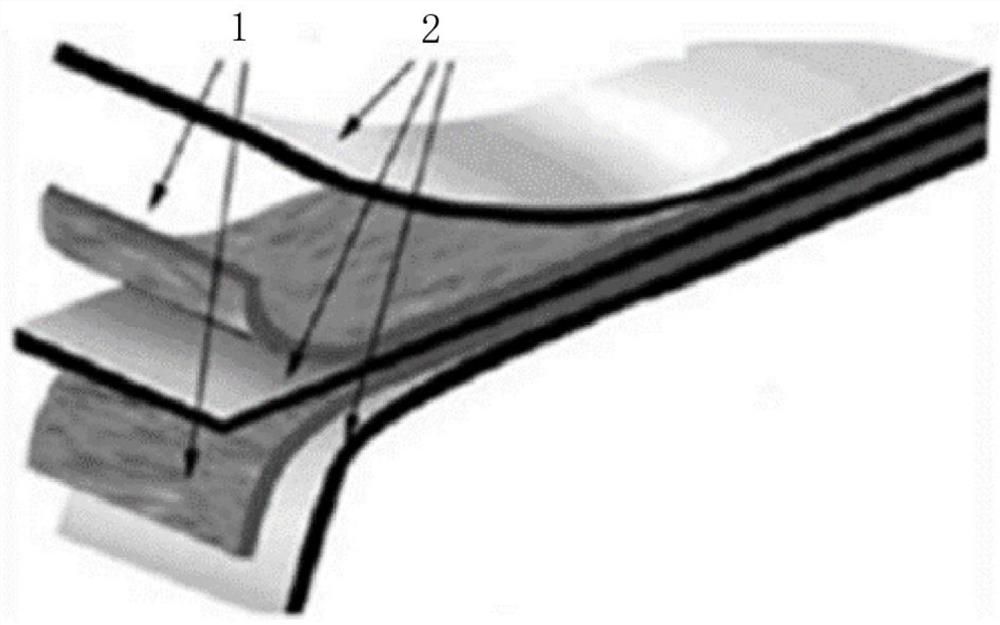

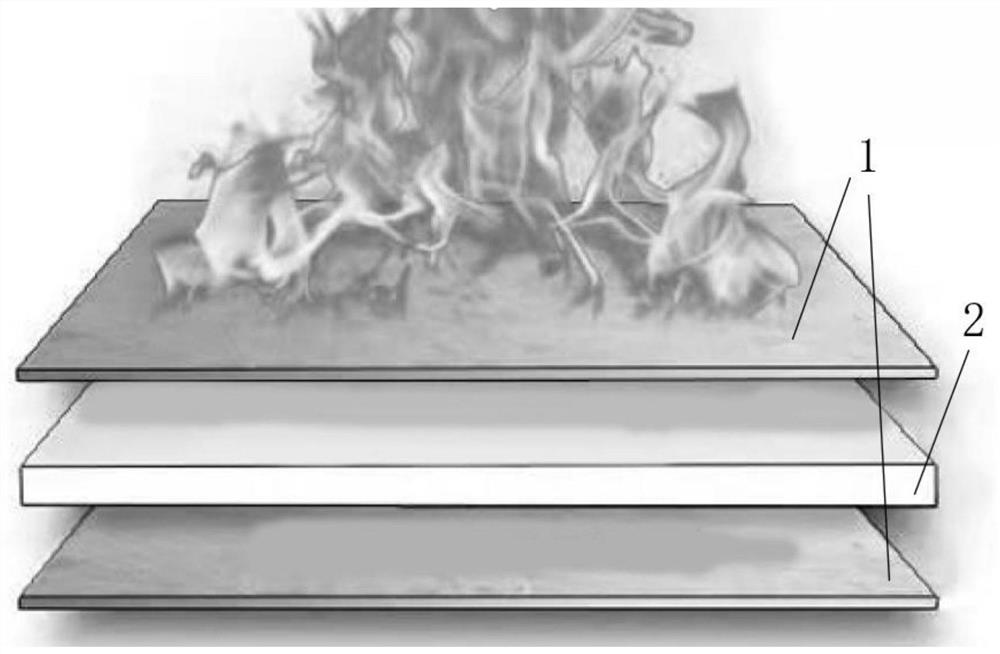

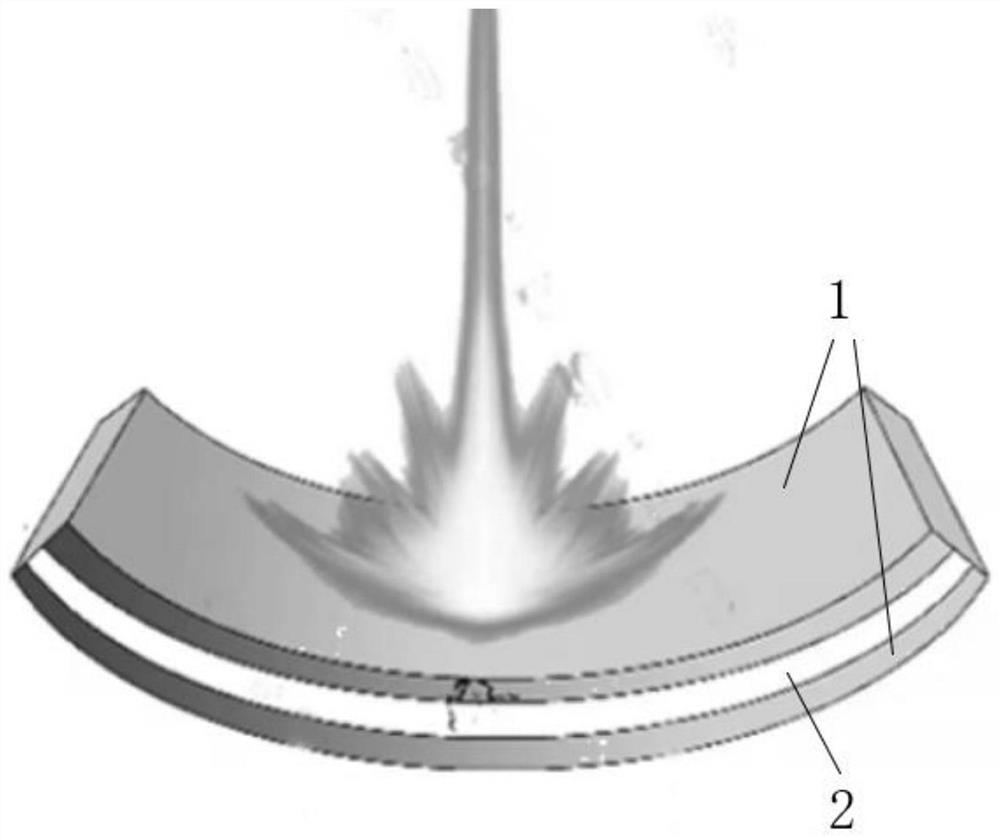

[0036] The flame-retardant layer 1 is made of fiber-reinforced composite material;

[0037] No. 1 explosion-proof layer 2 is made of aluminum alloy;

[0038] The second explosion-proof layer is made of adhesive.

[0039] A preparation method of a flame-retardant and explosion-proof new energy vehicle battery shell, comprising the following steps:

[0040] S1. First, select the materials for preparing the battery case, including the No. 1 explosion-proof layer 2 made of aluminum alloy, the flame-retardant layer 1 made of fiber-reinforced composite material, and the No. 2 explosion-proof layer made of adhesive;

[0041] S2, then design the battery shell, and set the direction of the layup according to the needs;

[0042] S3. Take one layer of No. 1 explosion-proof layer 2 as the inner core, and attach the preheated side of No. 2 explosion-proof layer to the upper and lower sides of No. 1 explosion-proof layer 2, and then attach the flame-retardant layer 1 to No. 1 explosion-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com