Preparation method and application of dimethyl benzyl acetate

A technology of dimethylbenzyl acetate and acetic anhydride is applied in the field of preparation of dimethylbenzyl acetate, and can solve the problems of low total yield of dimethylbenzyl acetate and high economic cost of tetrahydrofuran , to achieve the effect of increasing production volume and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

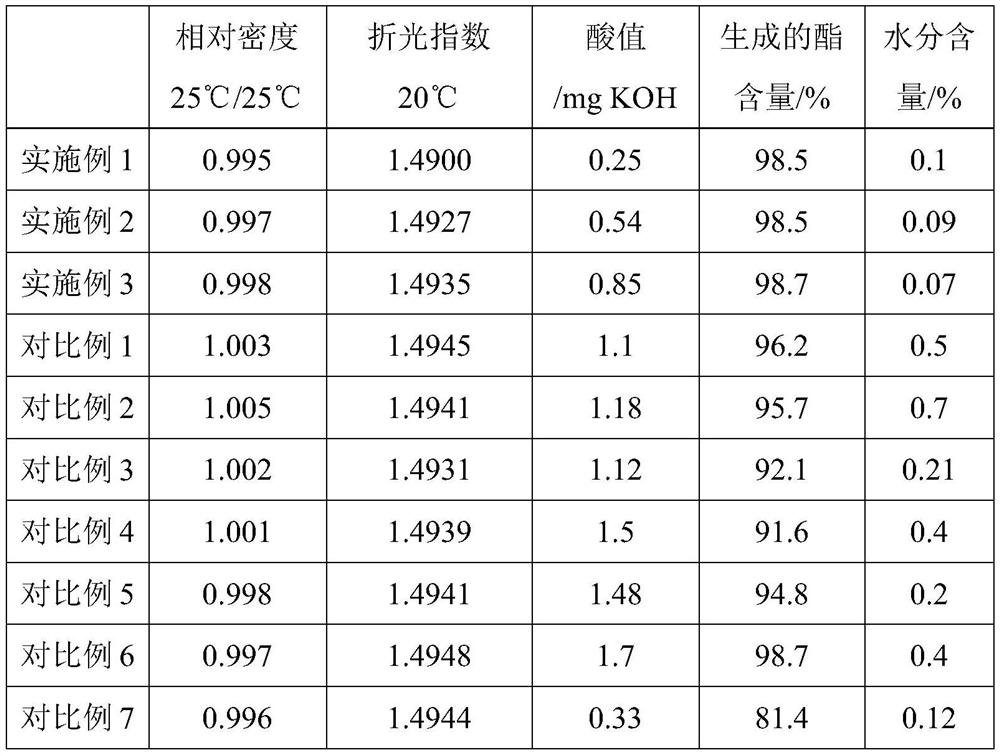

Examples

preparation example Construction

[0026] In order to solve the above problems, the first aspect of the present invention provides a preparation method of dimethylbenzyl acetate, the preparation raw materials include benzyl chloride, magnesium powder, acetone, acetic anhydride, toluene, ether, potassium carbonate, so The specific steps of the preparation method are as follows:

[0027] Add magnesium powder to S1 mixed solvent of toluene and ether;

[0028] S2 is added dropwise the mixed substance of benzyl chloride and acetone to react;

[0029] S3 adds potassium carbonate again, adds acetic anhydride again, and heats to reflux;

[0030] S4 is separated and purified to obtain dimethylbenzyl acetate.

[0031] Preferably, the specific steps of the preparation method are as follows:

[0032] Add magnesium powder to S1 mixed solvent of toluene and ether;

[0033] S2 is added dropwise the mixed substance A of benzyl chloride and acetone for 0.5-1h; then the mixed substance B of benzyl chloride and acetone is add...

Embodiment 1

[0055] Provided is a preparation method of dimethylbenzyl acetate, comprising the following steps:

[0056] S1 Mix 140ml of toluene and 60ml of ether, and add 5.6g of magnesium powder;

[0057] S2 was added dropwise 50ml of mixed substance A of benzyl chloride and acetone, reacted at 50°C for 0.5h, wherein the volume of benzyl chloride in mixed substance A was 35ml; then 50ml of mixed substance B of benzyl chloride and acetone was added dropwise, 50 The reaction was carried out at ℃ for 0.5h, wherein the volume of benzyl chloride in the mixed substance B was 15ml;

[0058] Add 5g potassium carbonate to S3, then add 55g acetic anhydride, and heat under reflux for 3h at 105°C;

[0059] S4 is separated and purified to obtain dimethylbenzyl acetate.

[0060] Provided is an application of dimethylbenzyl acetate, which can be used in the fields of food, cosmetics, skin care products, toiletries and fragrances.

Embodiment 2

[0062] Provided is a preparation method of dimethylbenzyl acetate, comprising the following steps:

[0063] S1 Mix 160ml of toluene and 40ml of ether, and add 5.6g of magnesium powder;

[0064] S2 was added dropwise 40ml of mixed substance A of benzyl chloride and acetone, and reacted at 50°C for 0.5h, wherein the volume of benzyl chloride in mixed substance A was 35ml; then 60ml of mixed substance B of benzyl chloride and acetone was added dropwise, and 50 The reaction was carried out at ℃ for 0.5h, wherein the volume of benzyl chloride in the mixed substance B was 15ml;

[0065] Add 5g potassium carbonate to S3, then add 60g acetic anhydride, and heat under reflux for 3h at 110°C;

[0066] S4 is separated and purified to obtain dimethylbenzyl acetate.

[0067] Provided is an application of dimethylbenzyl acetate, which can be used in the fields of food, cosmetics, skin care products, toiletries and fragrances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com